Flanging arrangement for wall hole of thin metal pipe

A thin metal flanging technology, applied in the field of processing equipment, can solve the problems of complex flanging process, difficult to improve production efficiency, unsmooth water flow channel, etc., and achieve the effect of simple flanging process and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

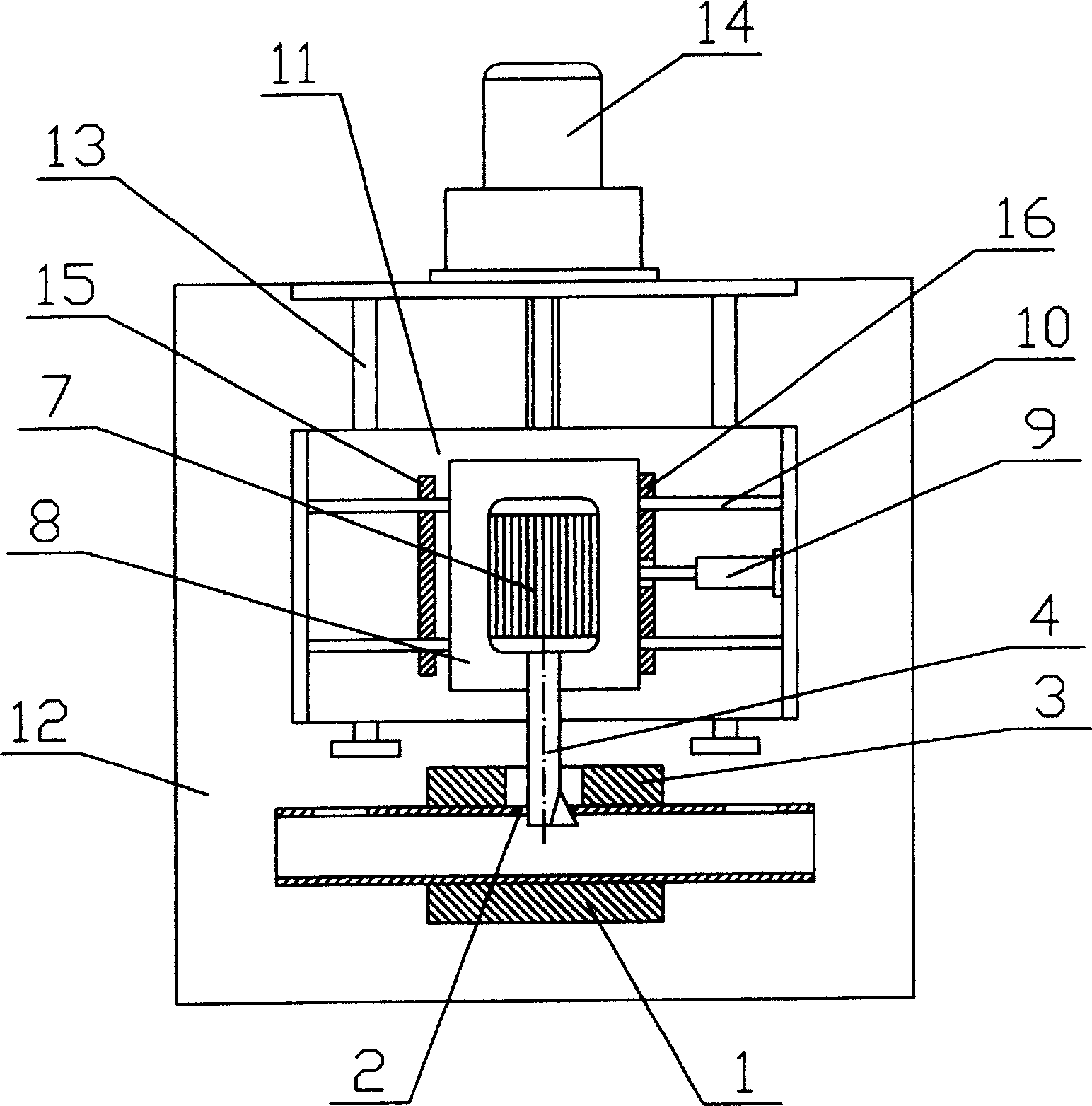

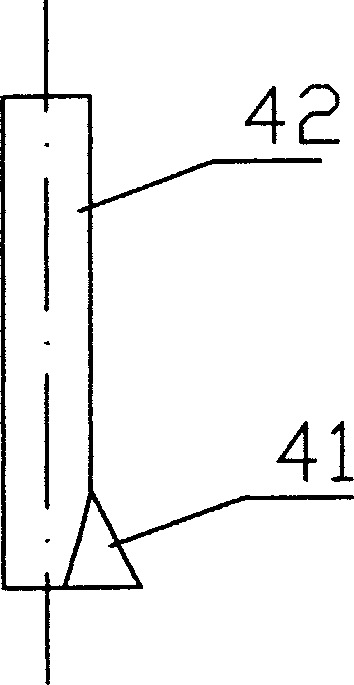

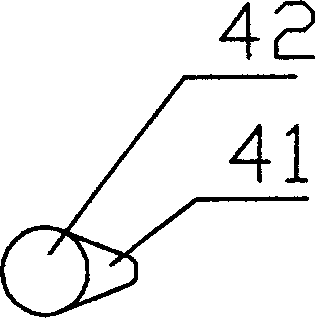

[0014] Example one: such as figure 1 , figure 2 , image 3 As shown, the outer flanging device for thin metal tube wall holes includes a clamp 1 for clamping thin-walled metal tubes, and an outer flanging die 3 corresponding to the thin metal tube wall holes 2, which can be flanged from the outside and the thin metal tube The wall hole 2 is inserted into the flanging tool 4 in the hole to drive the power device for the flanging tool 4 to work. The flanging blade 41 of the flanging tool 4 is arranged on one side of the shank 42 and the transverse direction of the flanging blade 41 is The eccentricity of the cross section along the axis of the tool holder 42 gradually increases from top to bottom. The distance from the distal end of the outer edge of the largest cross section of the flanging blade 41 to the axis of the tool holder 42 is greater than the radius of the unflanged pipe wall hole. The maximum cross section of the blade 41 and the circumscribed circle of the cross secti...

Embodiment 2

[0017] Embodiment 2: The flanging tool of this embodiment is exactly the same as that of the first embodiment, and the difference lies in the power device that drives the flanging tool to work, such as Figure 4 As shown, the power device includes a tool holder 5 that can be clamped on the outer flanging die 3 and is provided with an internal threaded hole. The internal threaded hole of the tool holder 5 is equipped with a tool holder 42 with a thread on the outer surface. The outer end of the handle 42 is fixedly provided with a rotating handle 6.

[0018] The technical solution of this embodiment is a manual processing method, and its working process is as follows: first, the clamp 1 clamps the thin-walled metal tube with the processed hole, the thin metal tube wall hole 2 is facing the outer flanging die 3, and the flanging tool is firstly clamped The head of 4 is inserted into the hole 2 of the thin metal pipe wall, and the knife holder 5 is clamped on the outer flanging die 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com