Flanging Tooling for Automobile Bushing

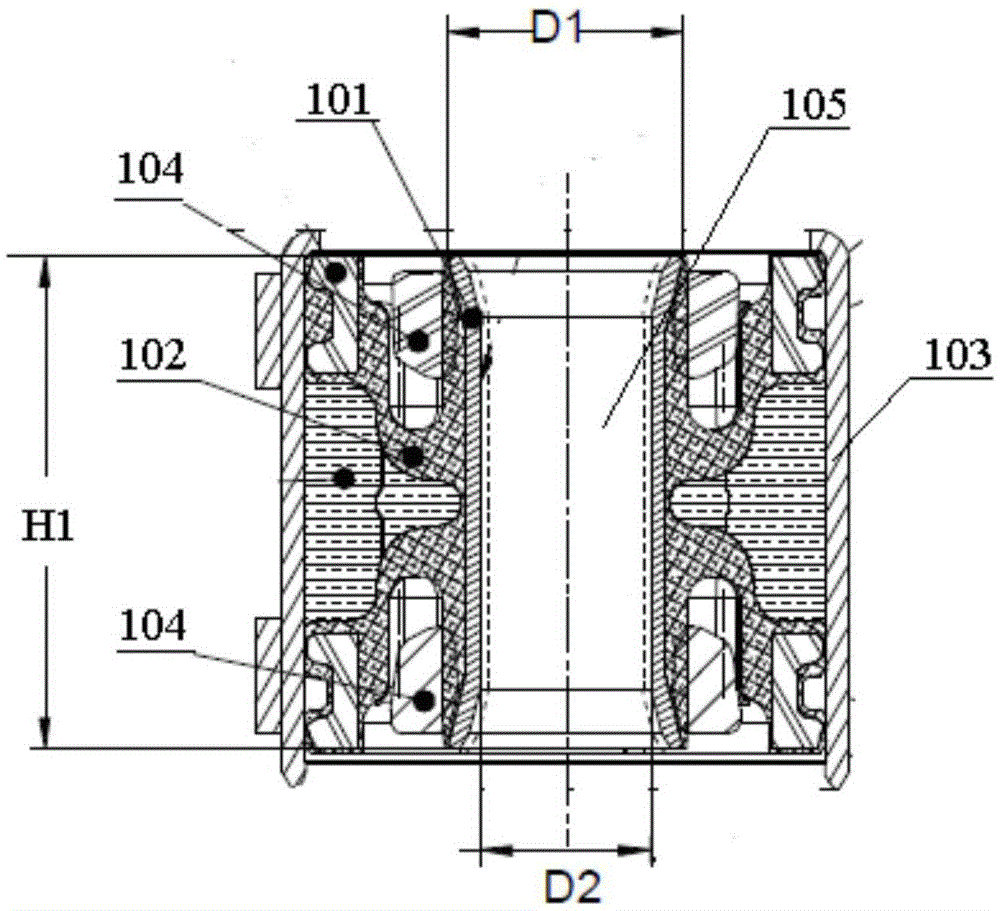

A technology of flanging tooling and bushings, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of stopper 104 falling off, etc., and achieve the effect of simple flanging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solutions of the present invention, the inventors of the present invention describe in detail below through specific embodiments and in conjunction with the accompanying drawings:

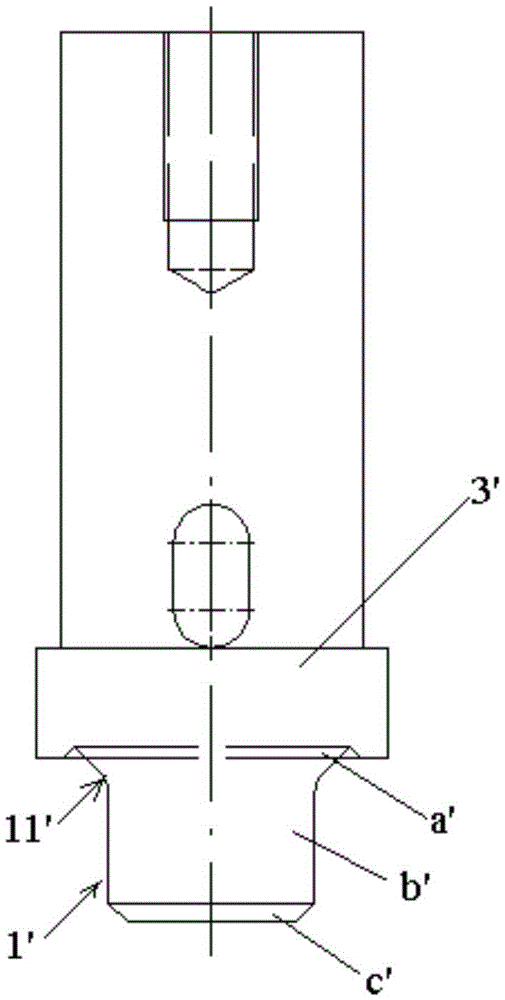

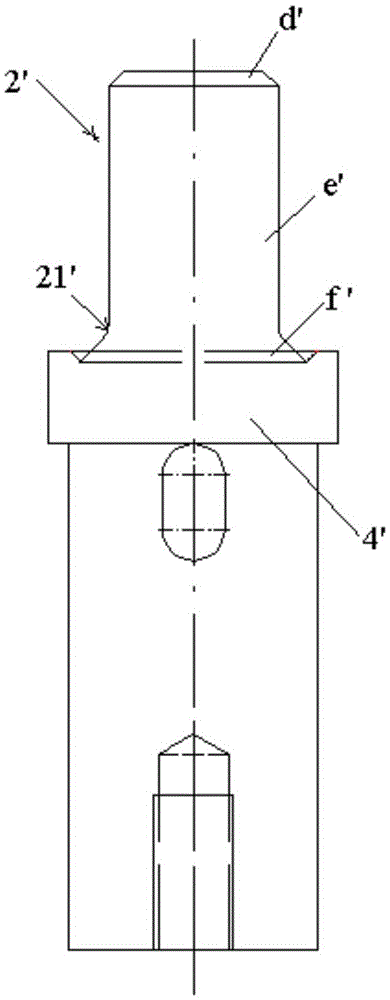

[0024] see Figure 4 , A flanging tool for automobile bushings of the present invention includes an upper flanging head 1 , a lower flanging head 2 , a left nozzle 5 and a right nozzle 6 . The lower surface of the lower flanging head 1 is fixed in the middle of the upper surface of the base 20 through the lower positioning table 4. The left and right sides of the base 20 are provided with a left column 7 and a right column 8 correspondingly, and the top and right A beam 9 is bridged between the top ends of the columns 8. The upper surface of the upper flanging head 1 is fixed on the beam 9 through the upper positioning table 3 and is located directly above the lower flanging head 2. The left nozzle 5 is installed on the left column 7. , the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com