Processing method of floral organic black tea

A technology of organic black tea and processing method, which is applied in tea spices, tea treatment before extraction, etc., can solve the problems of difficult control of black tea quality stability, difficult control of room temperature, low production efficiency, etc. Soup color red and bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

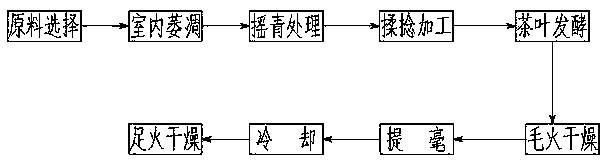

Method used

Image

Examples

Embodiment 1

[0034] (1) Selection of raw materials: From May to June every year, the hollow single buds from the tea trees in the Yinding Mountain tea garden that are free of pollution and do not use chemical fertilizers and pesticides are used as raw materials for fresh leaves. The tea buds are not required to be solid at the beginning.

[0035] (2) Indoor withering: Control the temperature of the withering room at 25°C, and place the fresh leaves harvested in step 1 in the withering room to wither naturally for 8-10 hours. After indoor withering, the moisture content of the fresh leaves is 66%-70%; The tea leaves shrink and become soft, the leaves feel soft when pinched by hand, there is no friction sound, the leaves form into agglomerates when held tightly, the leaves loosen slowly when the hands are released, the surface luster disappears, and the grassy smell of fresh leaves decreases.

[0036] (3) Shaking green treatment: put the withered fresh leaves into the green shaker for three s...

Embodiment 2

[0047] Embodiment 2: The basic steps are the same as in Example 1, except that in the step (3) shake the greens and greens for 2 times, shake the greens and greens for 2-3 minutes for the first time, and cool the greens and greens for 1-1.5 hours; 4 minutes, cool the greens for 1.5-2 hours, and skip step (7) at the same time.

Embodiment 3

[0048] Example 3: The steps of the base fabric are the same as in Example 1, omitting step (3) shake green treatment and step (7) extraction, and step (5) tea fermentation adopts the existing traditional black tea fermentation method.

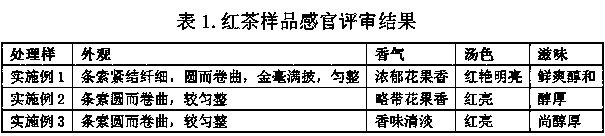

[0049] The black teas obtained after processing in Examples 1-3 were compared, and the sensory evaluation results of the prepared tea products are shown in Table 1. It can be seen from Table 1 that the flower-flavored organic black tea product obtained by the method of the present invention is tightly knotted and slender, round and curly, full of golden hairs, the aroma of dry tea is like comprehensive flavor types such as fruit, honey, flower, potato, etc., and the soup color is red Brilliant and bright, the taste is lively and sweet, the throat rhyme is long and refreshing, and if any step in the steps of the present invention is omitted, the effect will be greatly reduced.

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com