One-step preparation process of acid gossypol derivative with acid and acetone aqua

A technology of acetone aqueous solution and derivatives, which is applied in the separation/purification of carbonyl compounds, chemical recovery, organic chemistry, etc. It can solve the problems of inability to achieve reflux extraction, residual aniline gossypol, and industrial production hazards, and shorten the process cycle. The effect of increasing the yield and the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

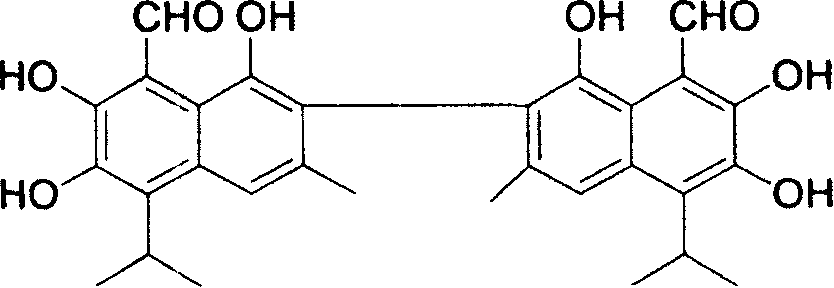

Image

Examples

Embodiment 1

[0013] Weigh 50 grams of cottonseed meal, put it into a 1-liter flask, extract with 2 times the amount of 75% (by volume) 1M acetone aqueous solution at room temperature for 1 hour, then raise the temperature to 50°C for heating and extraction for 4 hours, and concentrate the extract to the original 1 / 3 of the volume, placed at room temperature and then refrigerated for 8 hours, filtered by suction and washed with petroleum ether to obtain an orange-yellow precipitate, which was vacuum-dried and weighed 0.254 g. Its content was determined to be 99% by HPLC.

Embodiment 2

[0015] 100 grams of cottonseed were extracted according to the steps of Example 1, except that 1 times the amount of 95% 0.1M aqueous acetone acetate was extracted to obtain 0.508 grams of orange-yellow solid. Content: 99%

Embodiment 3

[0017] 500 grams of cottonseed were extracted according to the steps of Example 1, except that the temperature was raised to 35° C. and heated for 6 hours to obtain 3.305 grams of orange-yellow solid. Content: 98%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com