Assembly welding system for cone-shaped pipe circumferential weld

A welding system and conical tube technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of low efficiency, no automatic welding system, no single-tube conveying, positioning, grouping, and bottoming Circumferential Welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

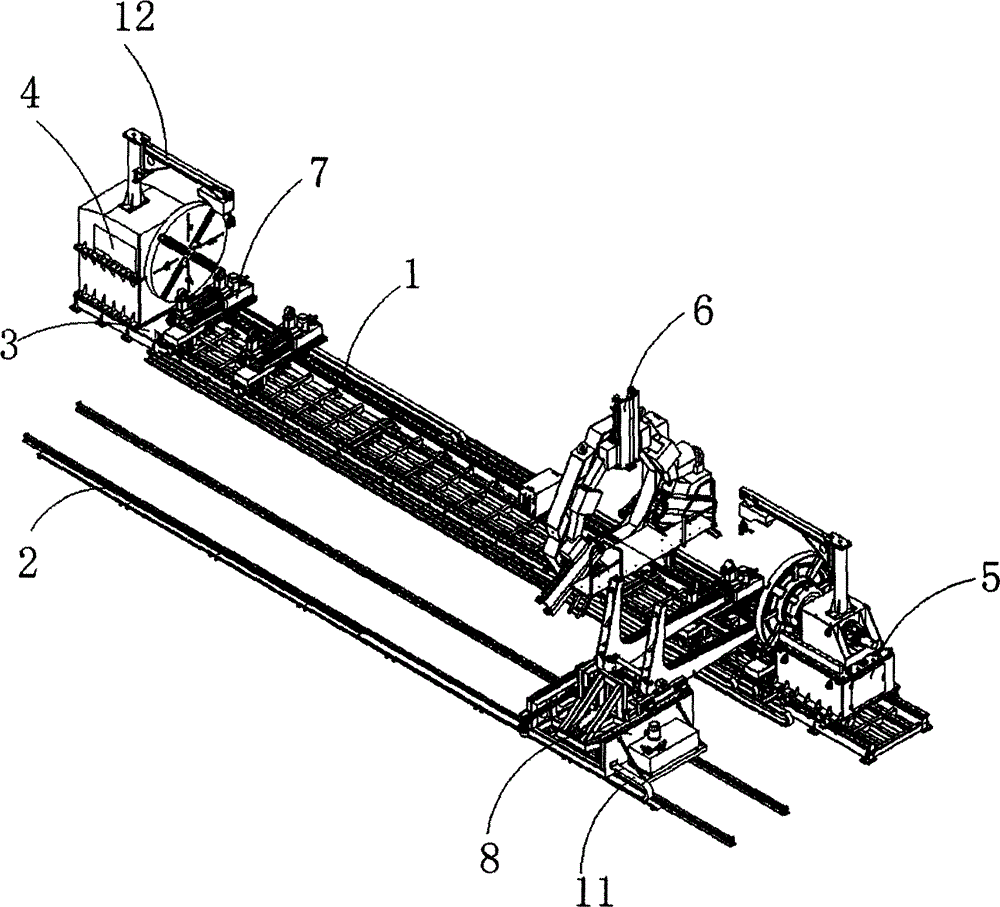

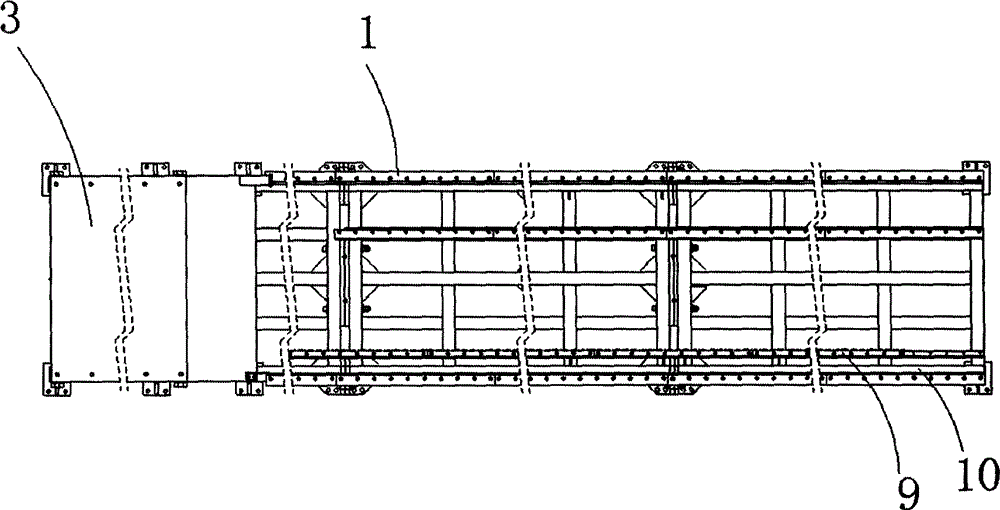

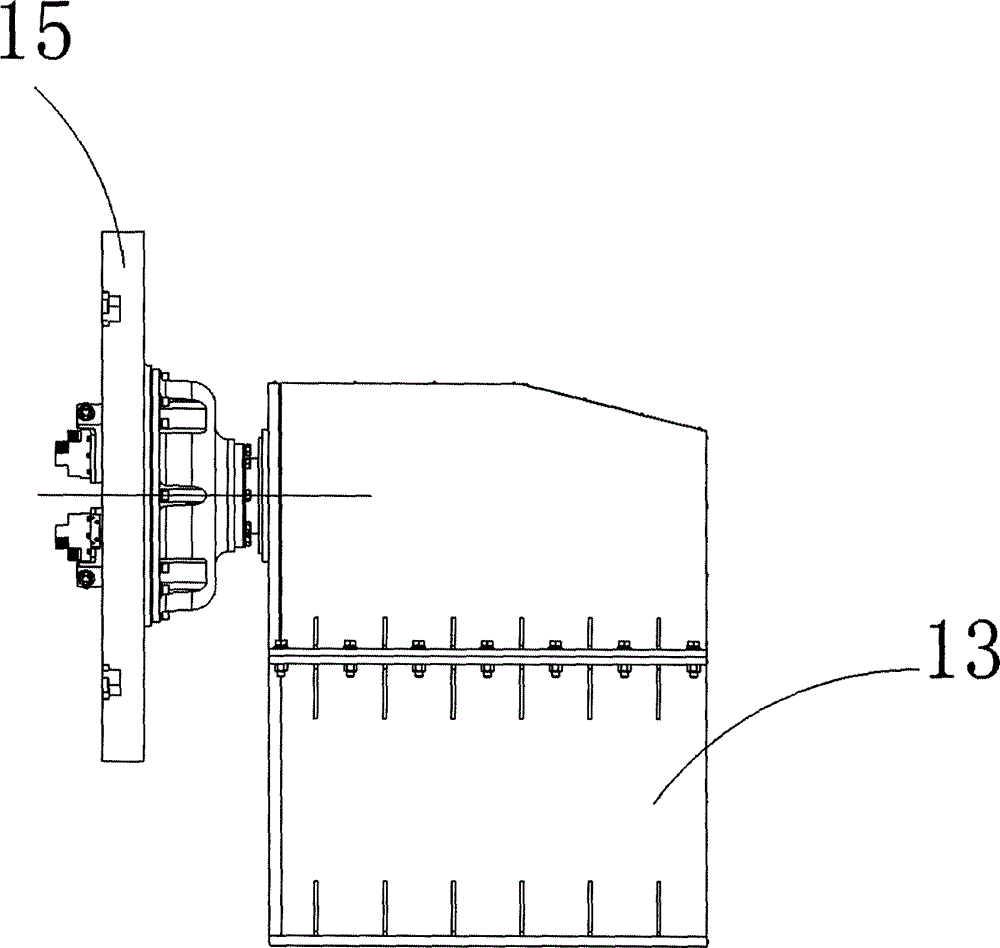

[0086] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 , Figure 27 , Figure 28 , Figure 30 , Figure 31 , Figure 32 , Figure 33 , Figure 34 , Figure 35 , Figure 36 , Figure 37 , Figure 38 , Figure 39 , Figure 40 , Figure 41 , Figure 42 , Figure 43 and Figure 44 As shown, a butt welding system for conical pipe annular seam group, including a base 1 and an overturning track 2, the left end of the base 1 is provided with a head seat mounting plate 3, and the head seat mounting plate 3 is provided with There is a head seat locking machine 4, the right end of the base 1 is provided with a displaceable tail stock locking machine 5, the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com