Corner-crossing transfer conveyer

A technology of conveyors and belt conveyors, applied in the field of transportation machinery, can solve problems such as unsafety, increased labor intensity of workers, and excessive manpower, and achieve the effects of increasing coal transportation speed, saving manpower, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

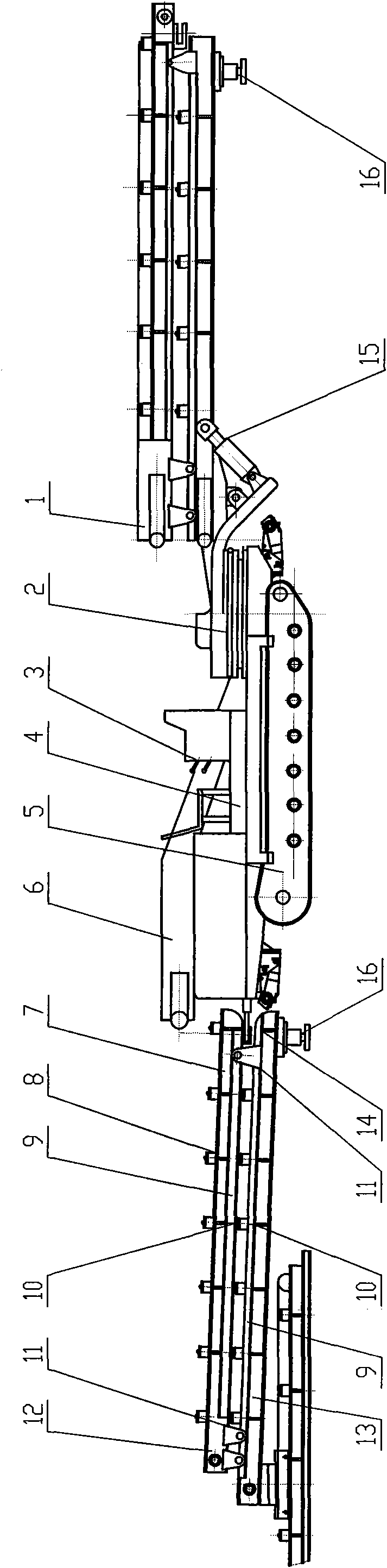

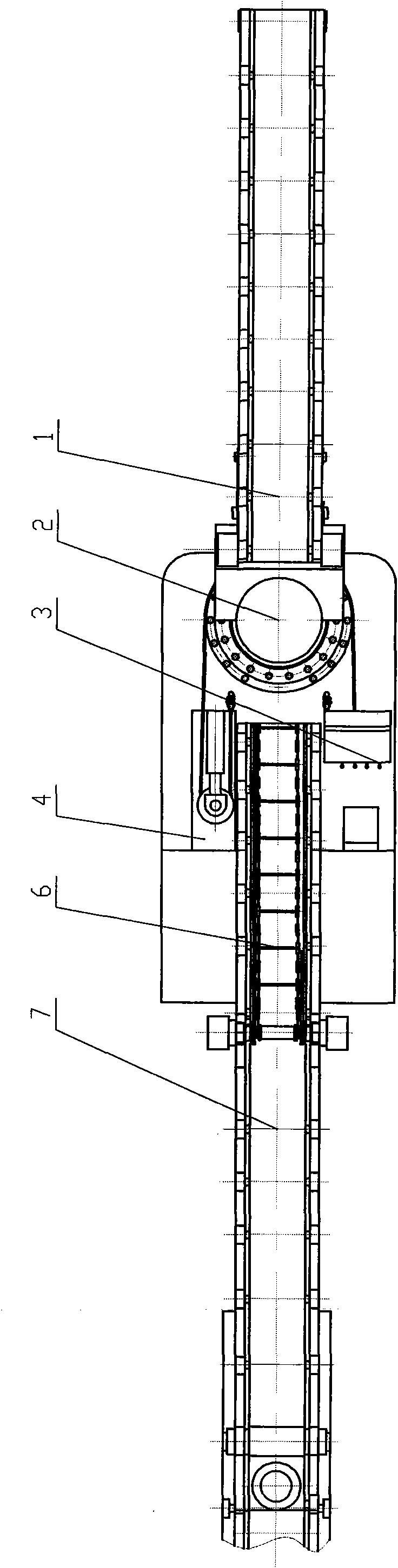

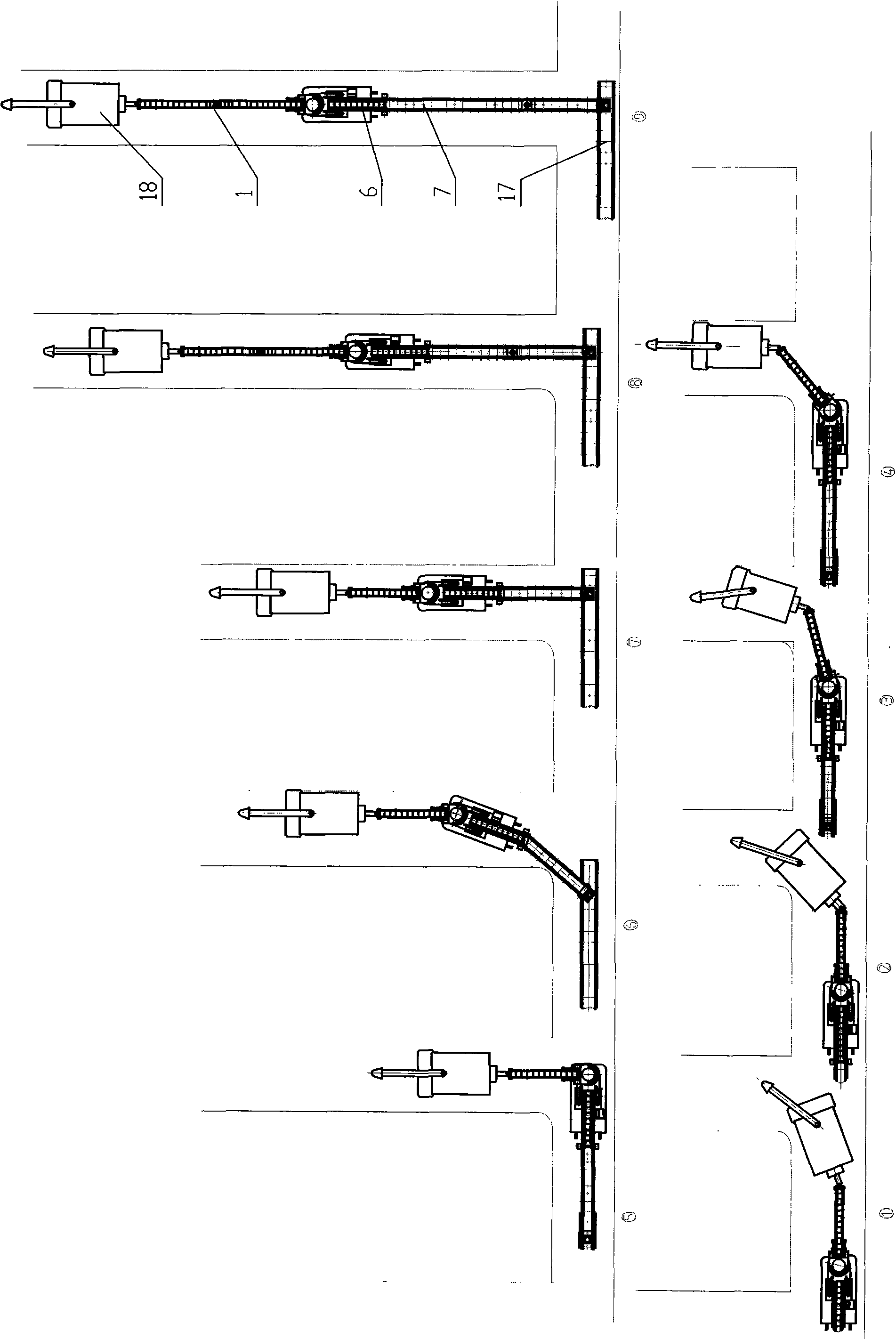

[0020] The present invention is made up of left and right running part 5, front conveyor 1, middle conveyor 6, tail conveyor 7, hydraulic system 3, and left and right running part 5 is equipped with frame 4, and front part is equipped with and can turn left and right 90 ° Turntable 2, organic front conveyor 1 is installed on turntable 2, intermediate conveyor 6 is installed in the middle of left and right walking parts 5, and organic tail conveyor 7 is hung at the tail of the machine.

[0021] The turntable 2 is hinged with the front conveyor 1, and a support oil cylinder 15 is installed between the turntable 2 and the front conveyor 2, so that the front conveyor can adjust the angle.

[0022] The lower belt machine tail 14 bottom left and right sides of conveyor 1 and tail conveyor 6 in front of the machine are respectively equipped with a front support oil cylinder 16.

[0023] The above-mentioned intermediate conveyor 6 is a scraper conveyor.

[0024] The front conveyor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com