Machine manufactured mould system for manufacturing combined open-web member

A component and mechanism technology, which is applied in the field of mechanical mold systems for combining hollow components in cast-in-place hollow floors, can solve the problems of unfavorable circulating heat energy of hollow components, large occupied space, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

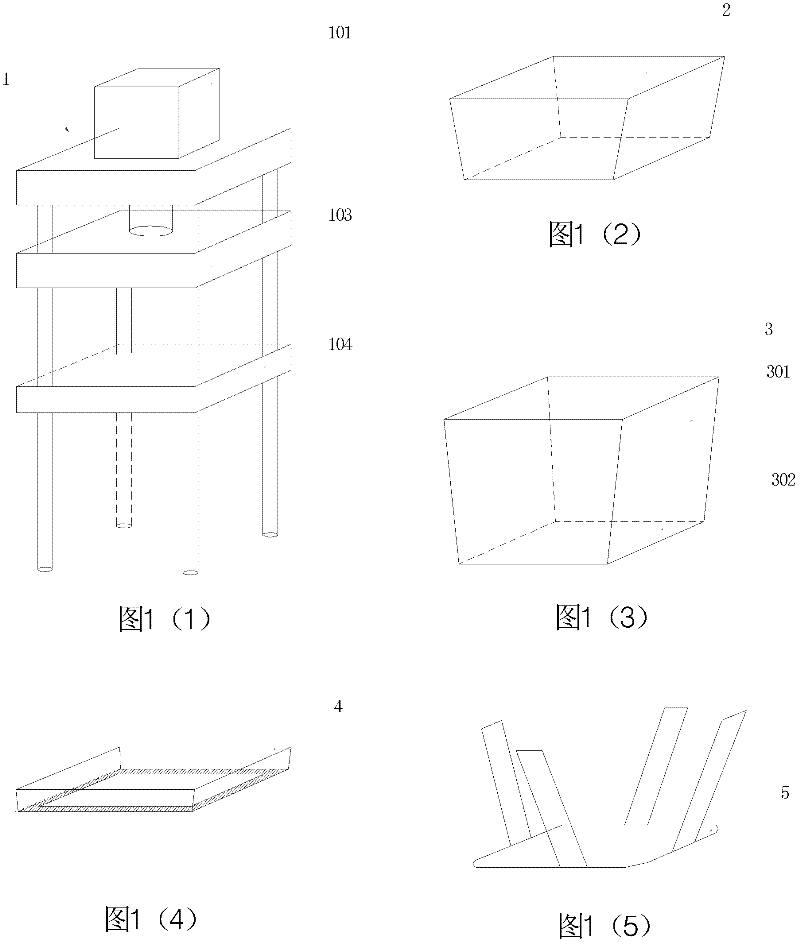

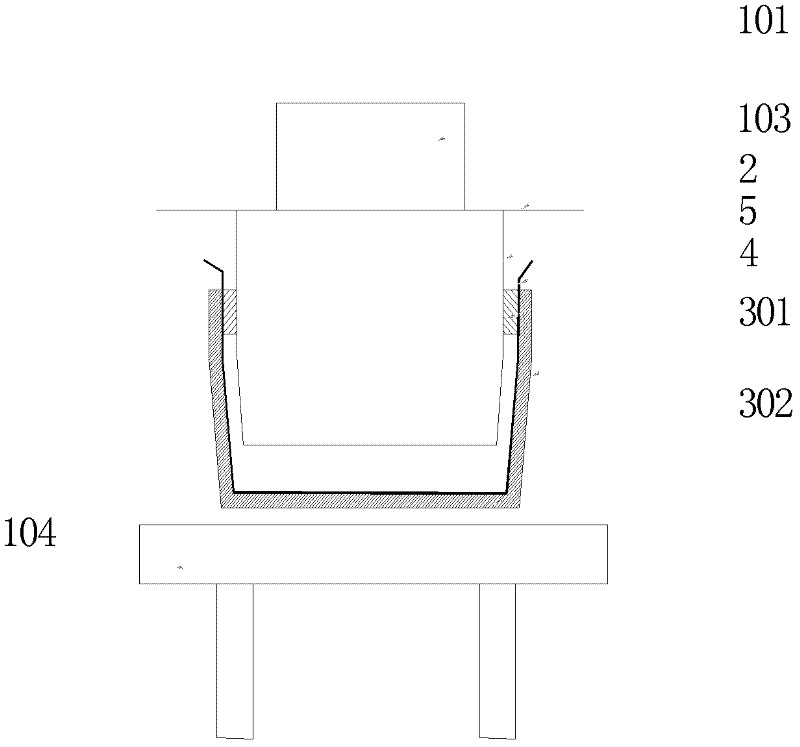

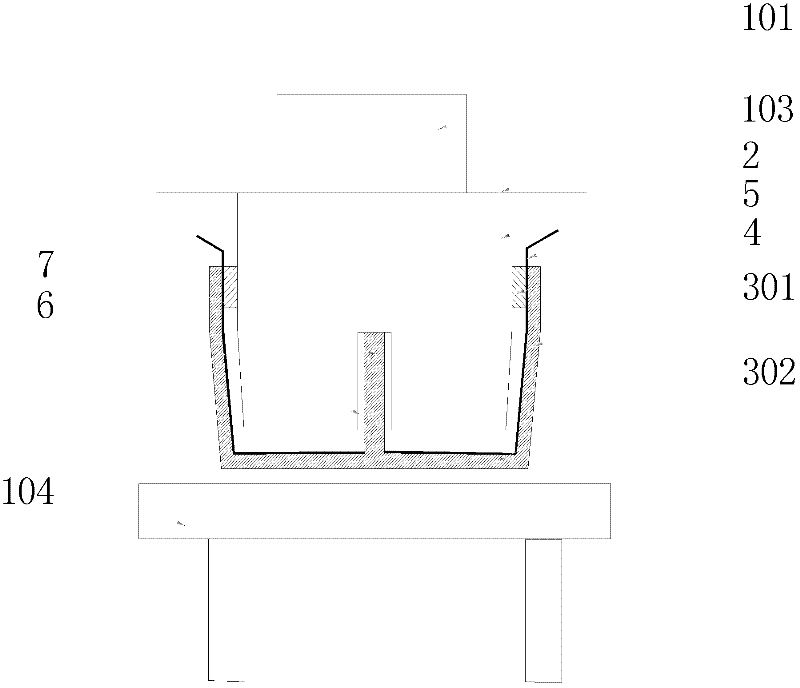

[0035] The technical scheme of the present invention is to utilize pressure machine and mold to make combined hollow member, attach figure 1 It is a schematic diagram of the individual structure of each component of the mechanism mold system, such as figure 1 As shown, the mechanism mold system includes a press machine 1 , an inner mold 2 , an outer mold 3 , a sealing plate 4 and a demoulding device 5 .

[0036] Such as figure 1 As shown in (1), the press machine 1 includes a hydraulic press 101 for press molding, a press plate 103 , and a base 104 . Such as figure 1 As shown in (2), the inner mold 2 is a square polyhedron, and the inner mold 2 squeezes the dry gelling material in the outer mold 3 under the drive of the pressure machine to form a cavity in the combined hollow member. Such as figure 1 (3), the outer mold 3 shown includes a surrounding side template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com