Forming machine of standing toilet pan

A molding machine and toilet technology, which is applied to ceramic molding machines, urinals, water supply devices, etc., can solve the problems of large model size, low efficiency, troubles, etc., reduce the physical requirements of employees, improve work efficiency, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

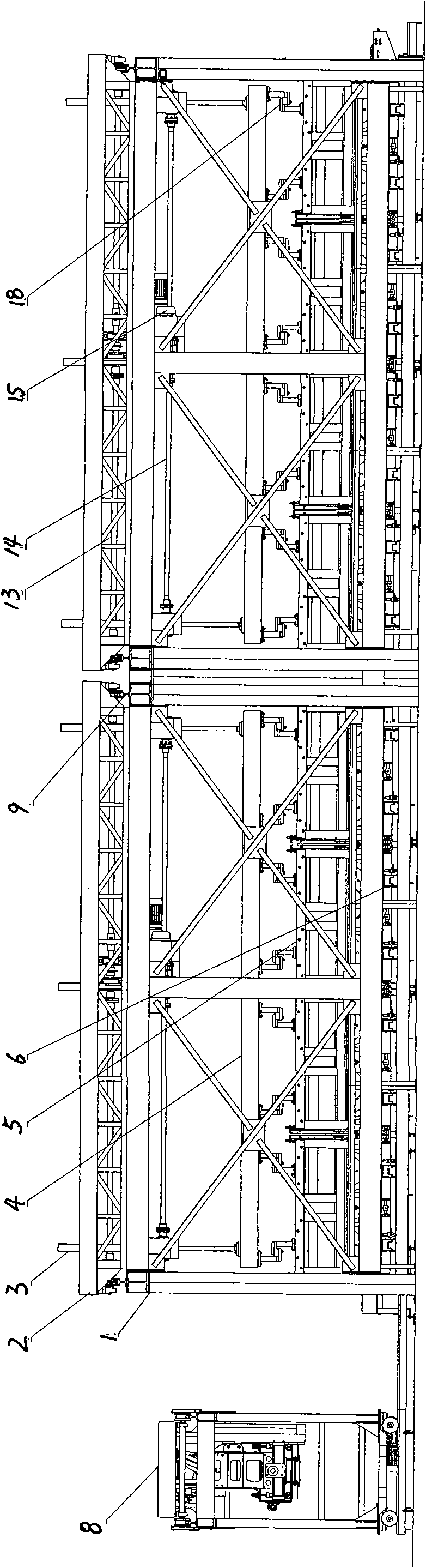

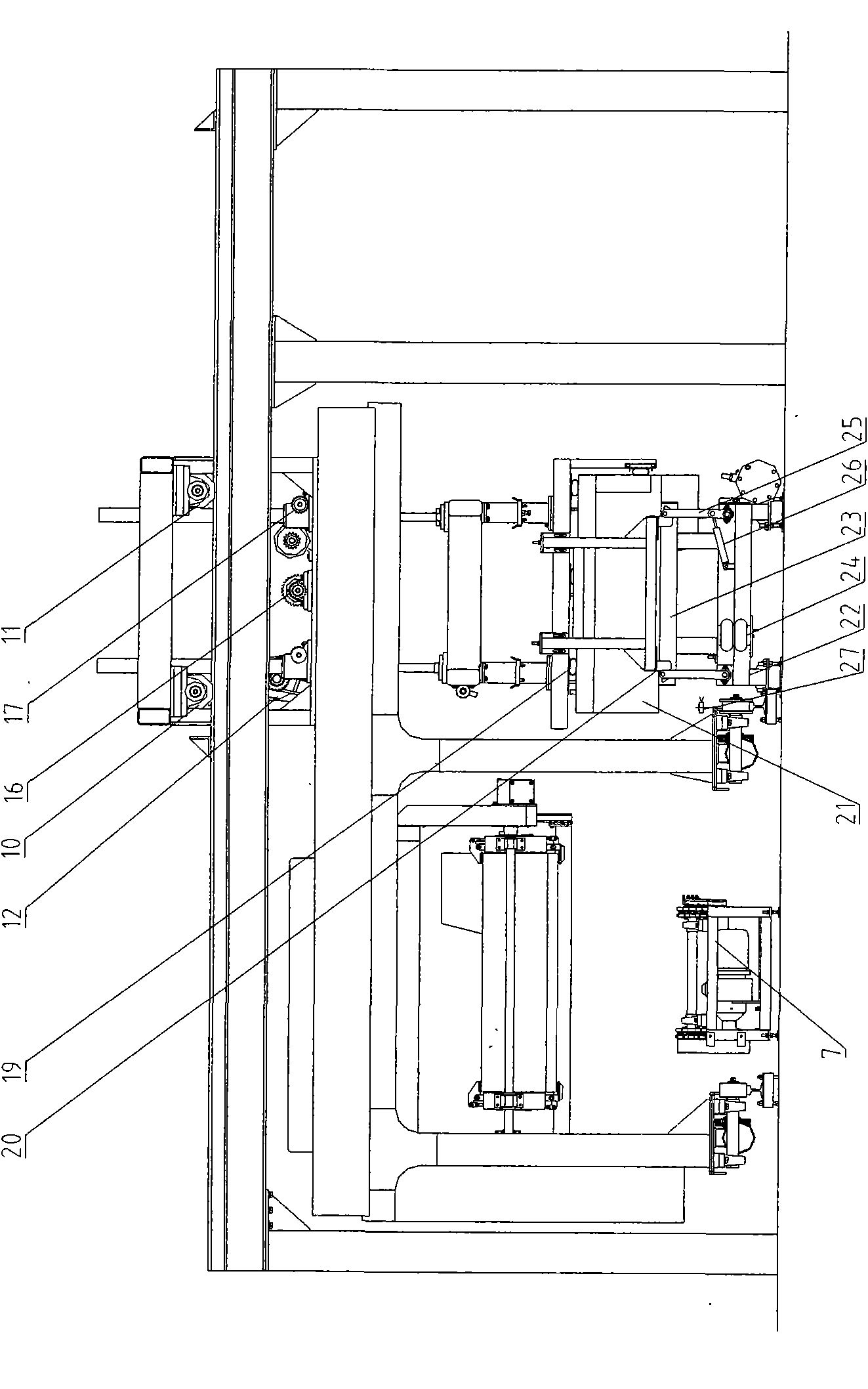

[0020] figure 1 , 2 Shown, the present invention is made up of main frame 1, mold opening crane 2, screw elevator 3, main girder 4, clamping hanger 5, forming line 6, side roller conveying line 7, automatic blanking machine 8.

[0021] The main frame 1 is divided into two symmetrical sections, which are connected as a whole with connectors in the middle, and light rails 9 are installed on the top crossbeam as the driving track, and the columns on both sides are supported and fixed with horizontal connections and scissor connections.

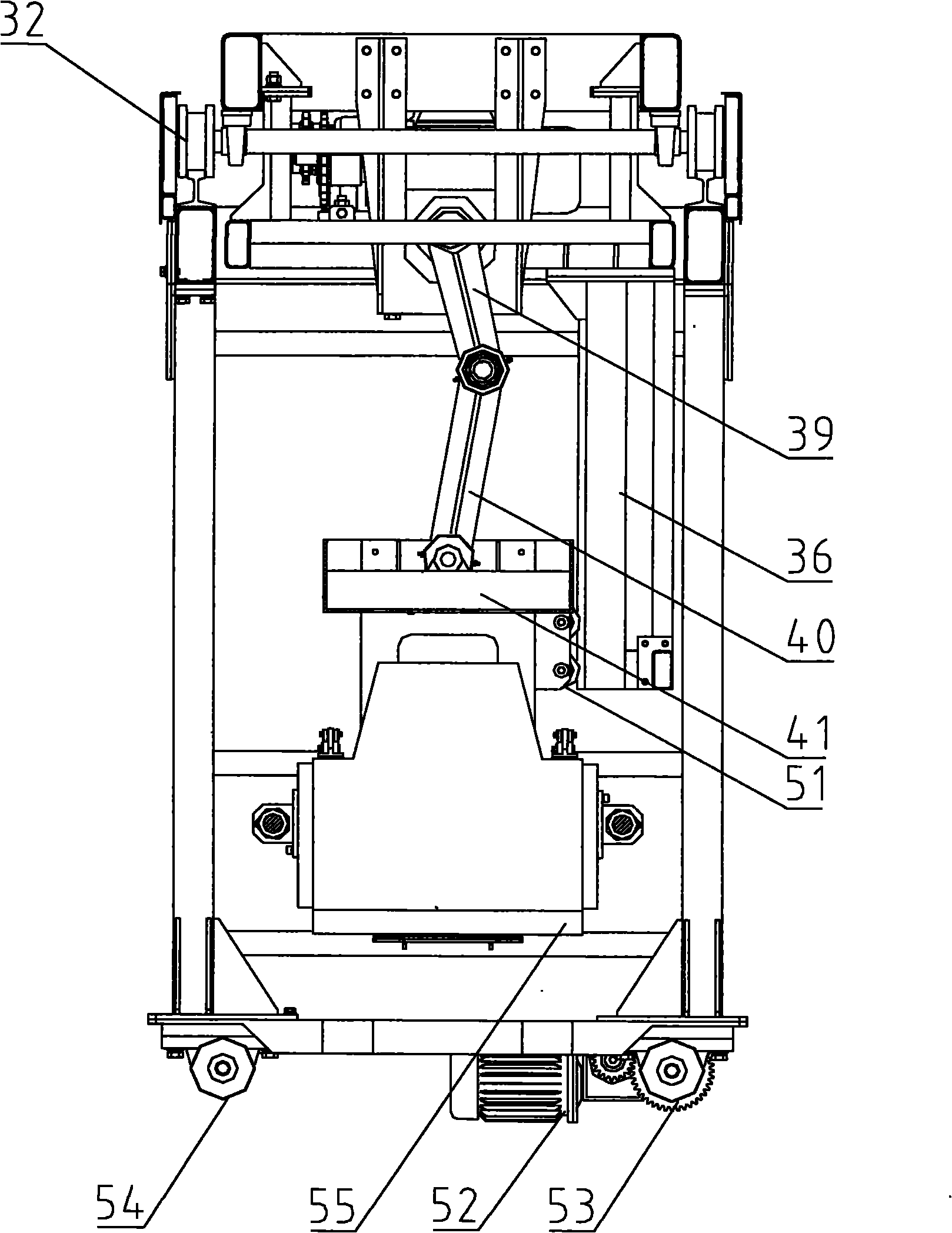

[0022] Two mold-opening cranes 2 are installed on each production line, and each crane has an independent driving device, which is equipped with 2 driving wheels 10 and 2 driven wheels 11, and the driving wheels 10 and driven wheels 11 have rims, and the driving device consists The stepless speed reducer 12 that motor directly connects is power, and is connected with driving shaft 13 chains, and driving wheel 10 is installed on the two ends of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com