Manufacturing method of fiber ball filtering material and its device

A technology of fiber ball filter material and production method, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., and can solve problems affecting the popularization and application of fiber ball filter materials, affecting the use of fiber ball filter materials, and high sales prices, etc. Problems, to achieve the effect of reasonable design, easy processing and manufacturing, and good implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method of the present invention has been described in the above-mentioned technical solution part. They are exactly the same and will not be repeated here.

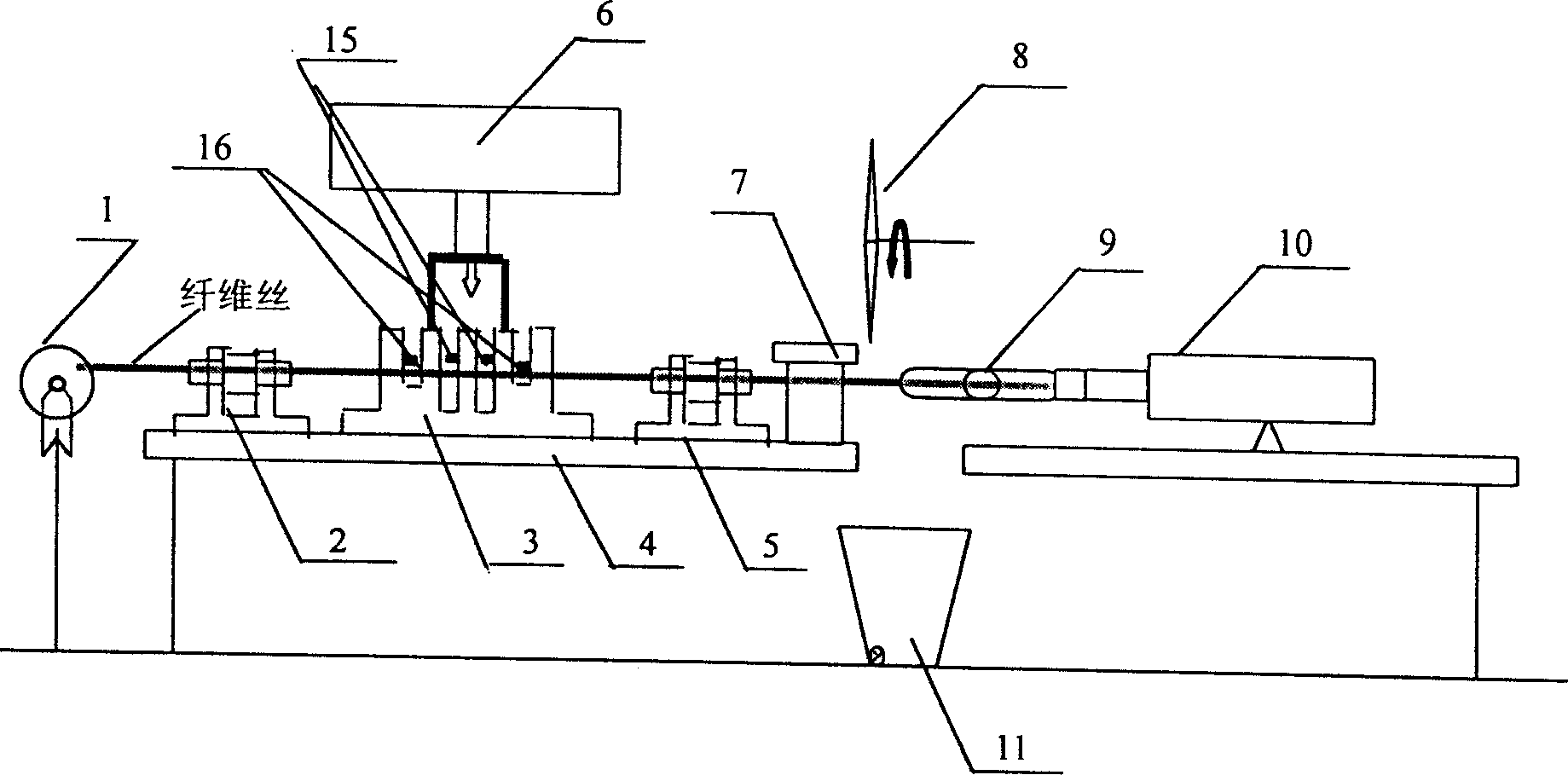

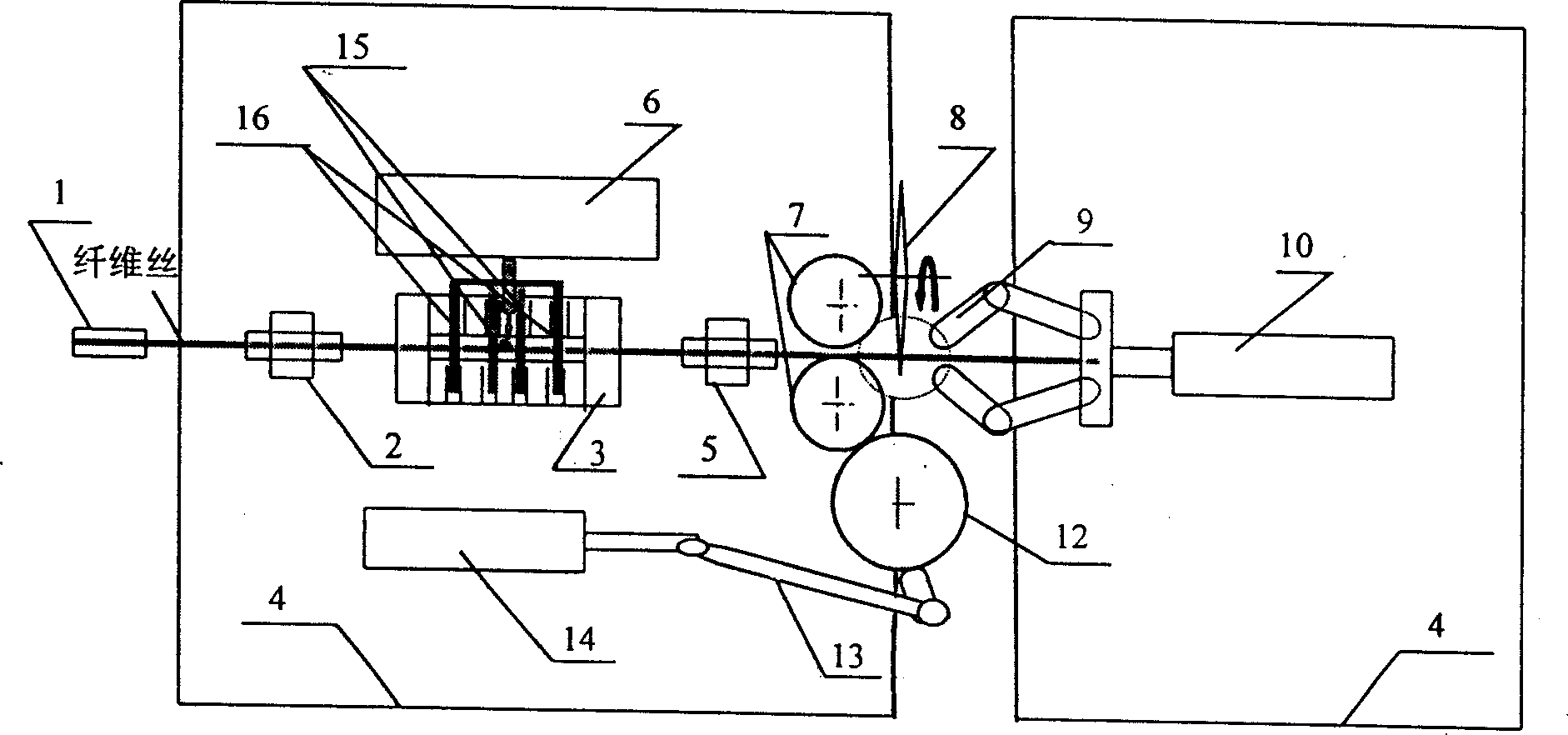

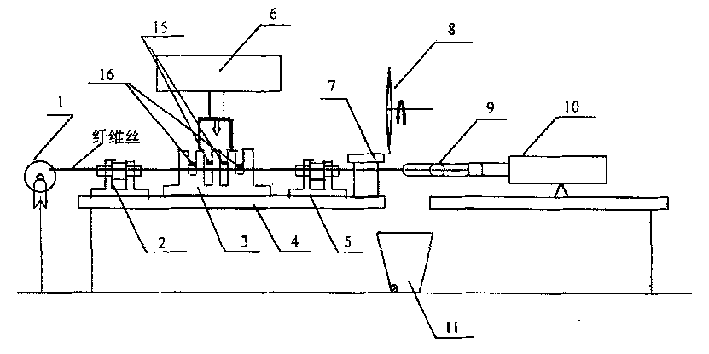

[0014] see figure 1 and figure 2 , to realize the device of the manufacturing method of fiber filter material, it is to arrange in order on the set machine base 4 the perforator 2 that can make the fiber bundle pass straight through, the welding seat 3 for fusing the fiber bundle, the adjustment perforator 5, by A clamping wheel 7 composed of double transmission wheels and a double-link holder 9 capable of clamping fiber bundles. The front end of the machine base 4 places the fiber bundle spool 1, which is connected to the clamper 9 to make it possible to make the cylinder 10 of the double-linkage linkage, one side of a transmission wheel in the clamping wheel 7 meshes with the friction ratchet 12, and the friction ratchet 12 passes through Transmission rod 13 realizes distance rotation by cylinder 14 . An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com