Adapter and method for preventing back flow of gas

An adapter and gas technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, gaseous chemical plating, etc., can solve the problems of reduced production capacity, reduced pump vacuum efficiency, and difficult cleaning of deposits in exhaust pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] As mentioned above, according to the prior art, the water vapor in the local brushing machine will flow countercurrently along the exhaust pipe to produce chemical reactions with reactive gases, reactive gases that have not completely reacted or by-products, and will Deposits form in the pipe wall. Therefore, the present invention provides an adapter for preventing gas backflow, which includes an outer tube and an inner tube.

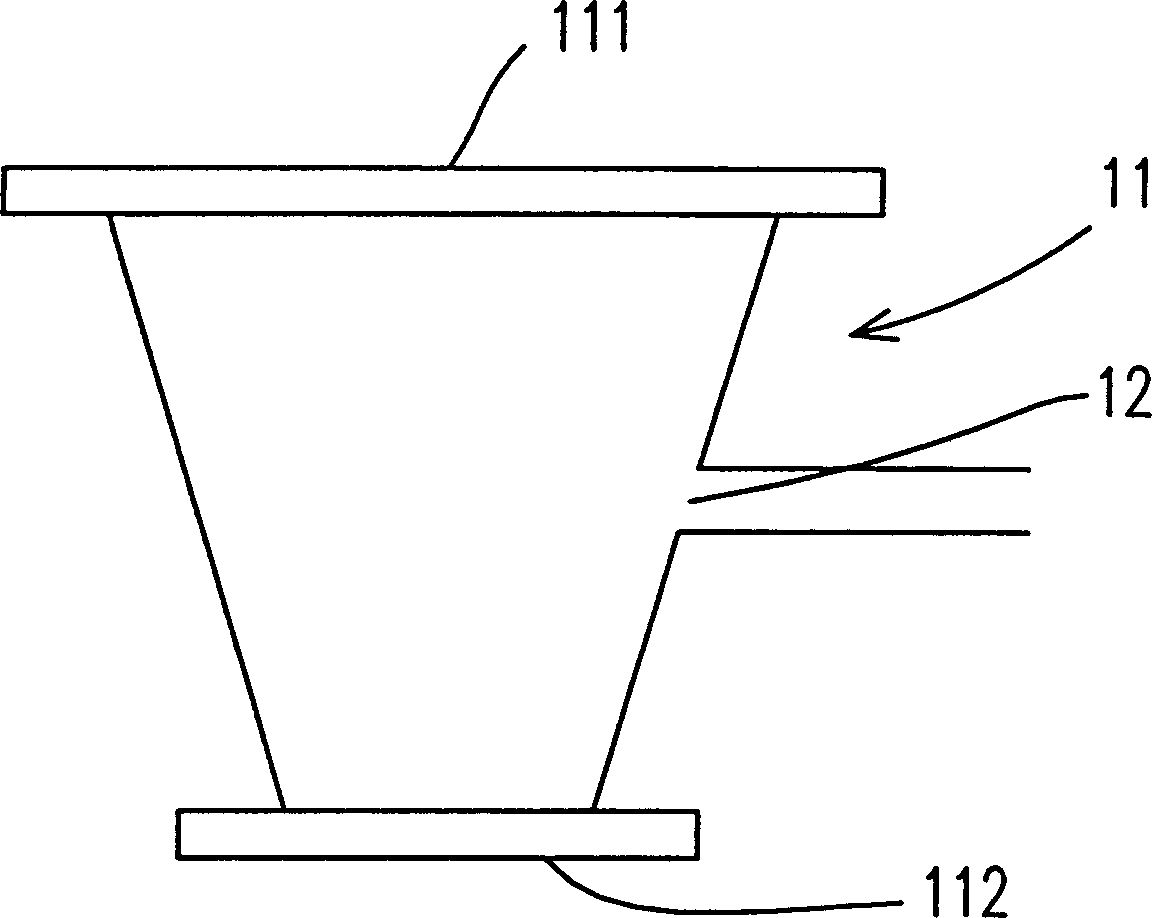

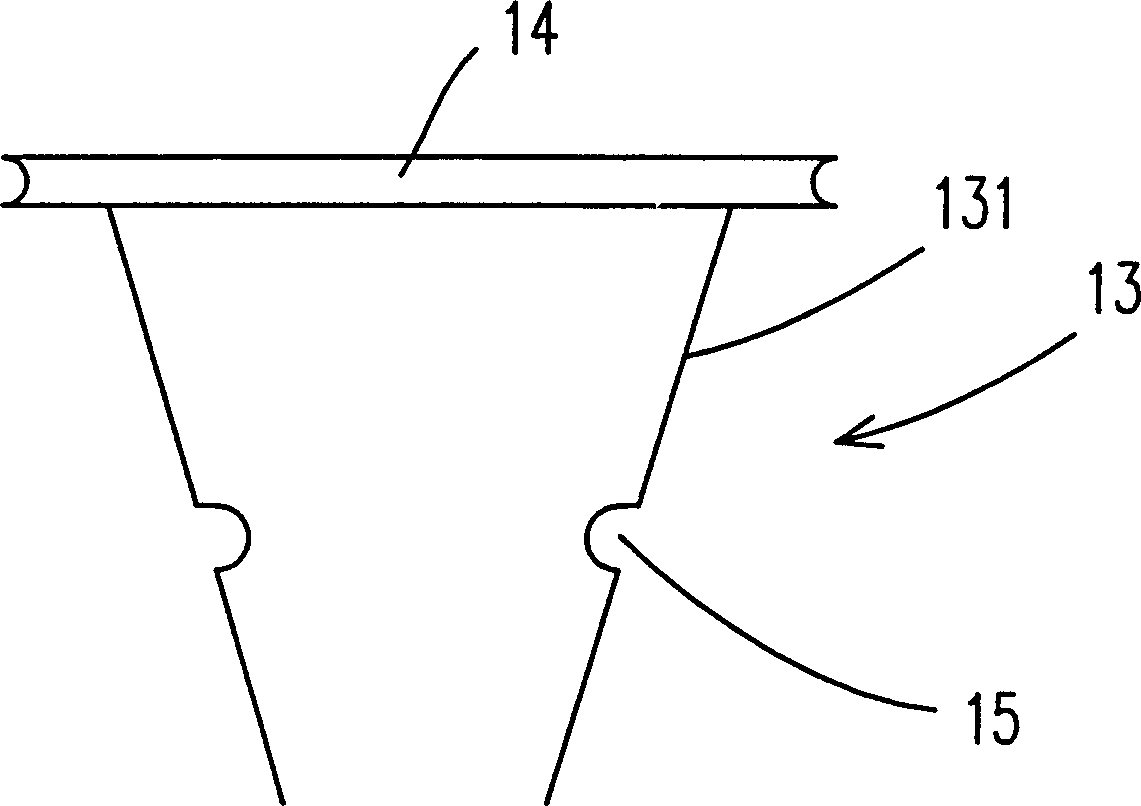

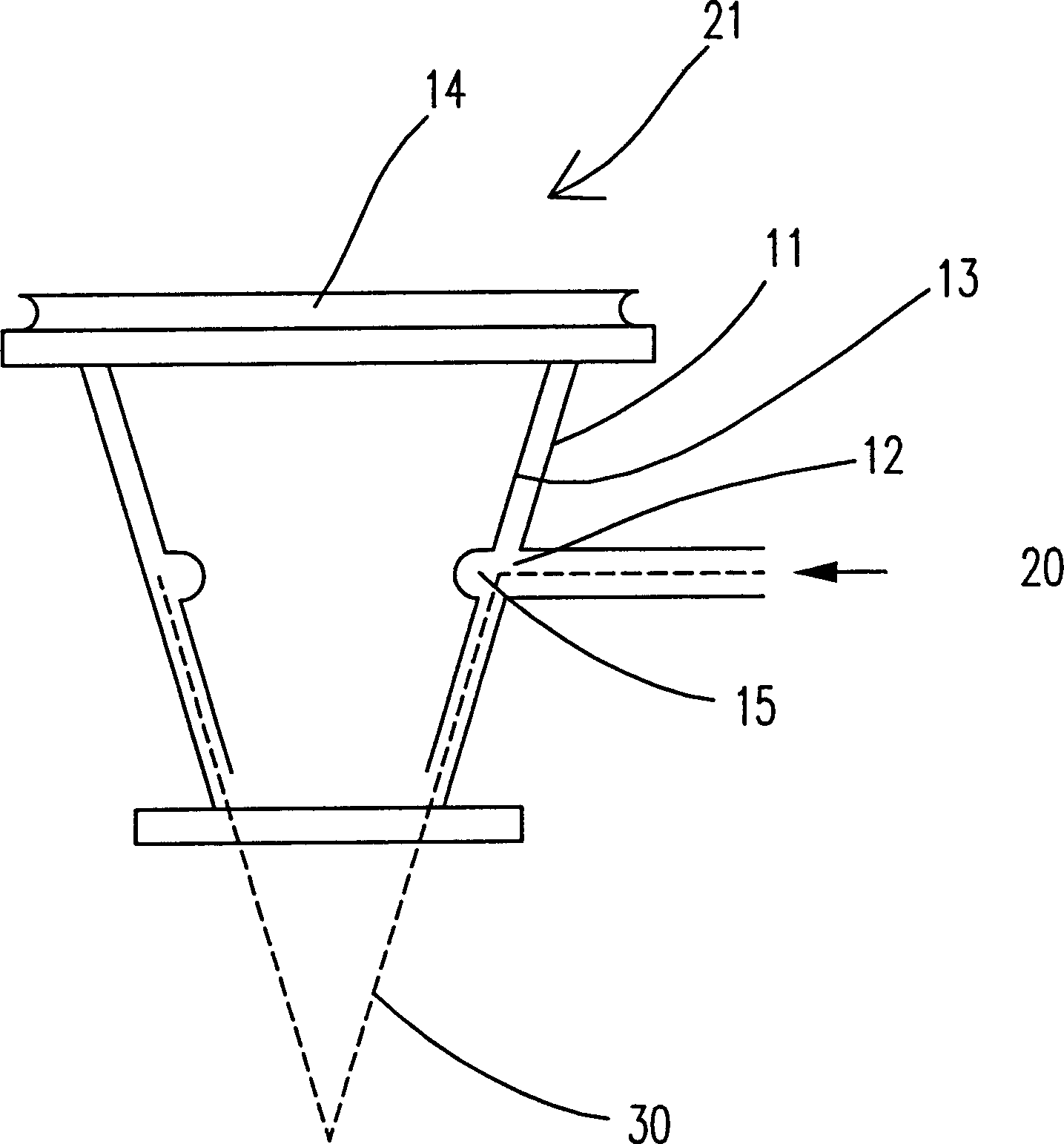

[0043] Please refer to Fig. 1(a), which is a side view of the structure of the outer tube 11 of the adapter of the present invention. The outer tube 11 of the adapter for preventing gas backflow of the present invention is in the shape of a funnel, and the upper opening 111 and the lower opening 112 are used to connect with the first pipeline 17 and the second pipeline 18 respectively (see image 3 ) connection, the calibers of the upper opening 111 and the lower opening 112 correspond to the diameters of the first pipeline 17 and the second pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com