Clamp lifting tool used for clamping steel plates in uniform thickness manner

A clamping clip and equal-thickness technology, which is applied to load hanging components, transportation and packaging, etc., can solve the problem of not being able to achieve equal-thickness clamping, and achieve the effect of simple structure and high overall rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

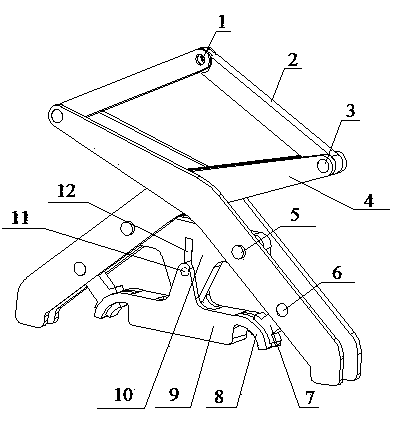

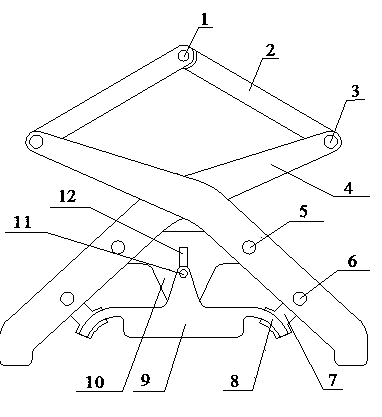

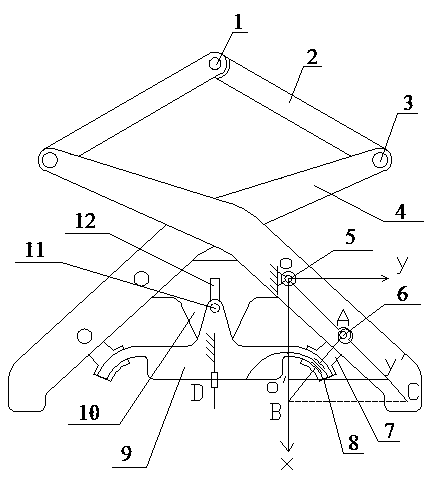

[0014] see figure 1 , figure 2 , the steel plate equal thickness clamping clamp spreader described in the present embodiment is made up of two connecting rods 2, two groups of clamp arms 4, a guide plate 10, two guide rail connecting rods 7 and a positioning plate 9, two The upper ends of the connecting rods 2 are connected through the first pin shaft 1, and are used to connect lifting devices such as ropes; 4 are relatively placed left and right, and are composed of four steel plates with the same structure. Each steel plate has a pin hole at the upper end, middle part, and lower part respectively. The guide plate 10 is located between the two steel plates of each group of tong arms 2, and the two ends of the guide plate 10 are respectively connected to the two groups of tong arms 4 through the third pin shaft 5 and the pin hole in the middle of the tong arm 4, and the guide plate 10 is arranged in the middle. There are long slotted holes 12 in the vertical direction; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com