Method for machining high-rigidity inner ring flange of automobile hub bearing unit

An automobile wheel hub and processing method technology, applied in the field of metal processing, can solve the problems of difficult processing, complex and asymmetric inner ring flange structure, etc., and achieve the effects of improving surface rigidity, increasing mold life, and improving overall rigidity

Inactive Publication Date: 2017-08-29

江苏昊鹏机械有限公司 +1

View PDF9 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the complex and asymmetric structure of the inner ring fla

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

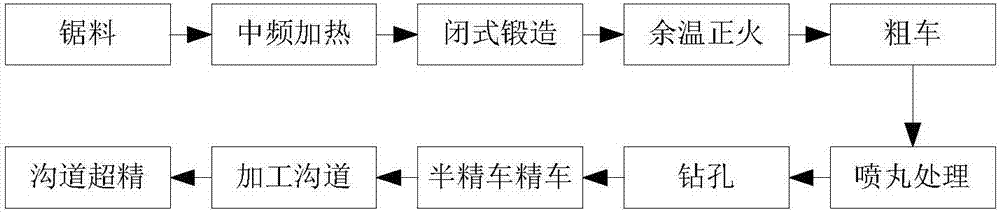

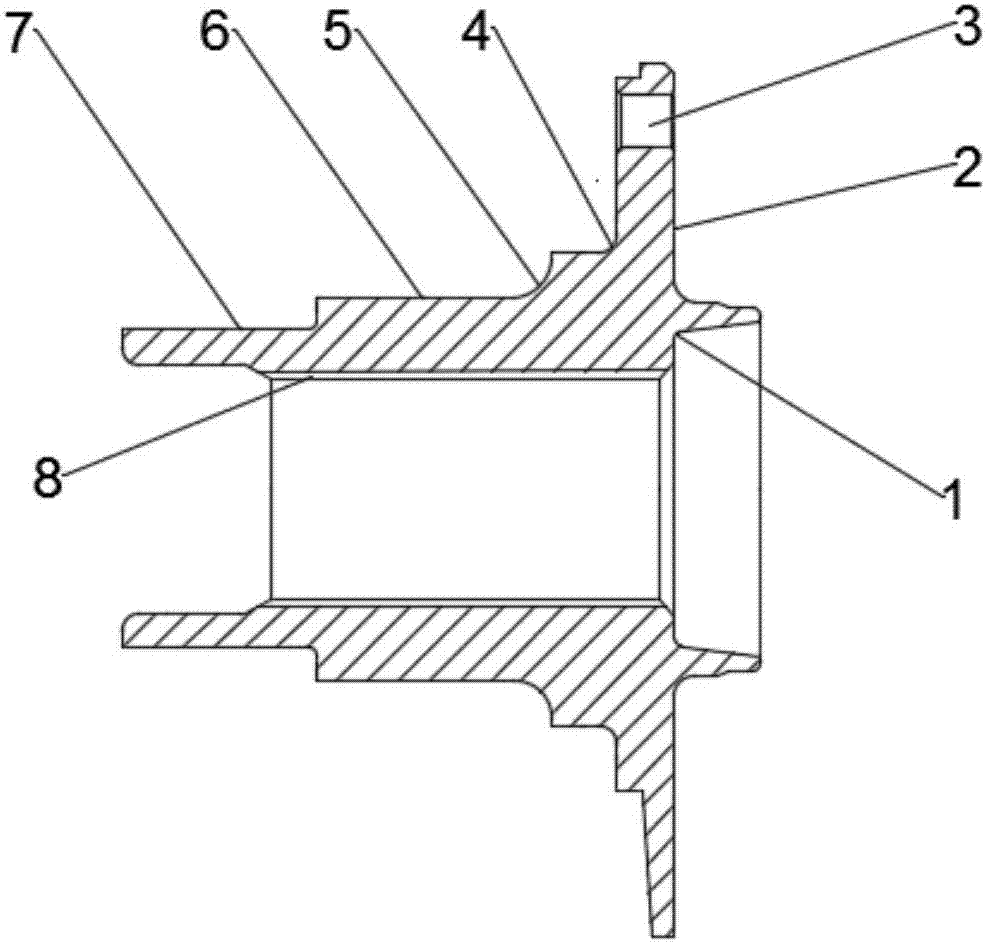

The invention provides a method for machining a high-rigidity inner ring flange of an automobile hub bearing unit. The method comprises the steps of 1, sawing materials; 2, performing medium-frequency heating; 3, performing closed type forging; 4, performing residual-temperature normalizing and low-temperature tempering; 5, performing cooling and rough turning; 6, performing double shot blasting treatment; 7, drilling a hole, specifically, machining a flange plate hole by adopting a drill; 8, performing semi-finish turning, finish turning and forming, specifically, performing semi-finish turning and finish turning treatment on a flange plate obtained in the step 7; and 9, machining a channel and performing superfinishing on the channel.

Description

technical field [0001] The invention relates to a processing method for a high-rigidity inner ring flange of an automobile hub bearing unit, belonging to the field of metal processing. Background technique [0002] The main function of the automobile hub bearing unit is to bear the weight of the vehicle transmitted through the suspension system, the axial load generated by the steering, transmit the torque transmitted by the gearbox and the drive shaft, and provide accurate guidance for the rotation of the hub, etc. Hub bearing units mainly include inner rings, outer rings, rolling elements, cages and other components. The third-generation hub bearing unit that has developed to the present mainstream is composed of an outer ring with a flange connected to the suspension and an inner ring with a flange connected to the brake disc and steel ring, and is similar to the second-generation hub bearing unit. Different, the third generation hub bearing unit integrates the ABS senso...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P15/00

CPCB23P15/00

Inventor 丁宏山臧利国刘建赵振东严冬霞尹荣栋

Owner 江苏昊鹏机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com