Injection molded centrifugal air impeller

a centrifugal air and injection molding technology, applied in the direction of propulsive elements, vessel construction, marine propulsion, etc., can solve problems such as reducing efficiency, and achieve the effect of reducing the likelihood of flashing and minimizing mold wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

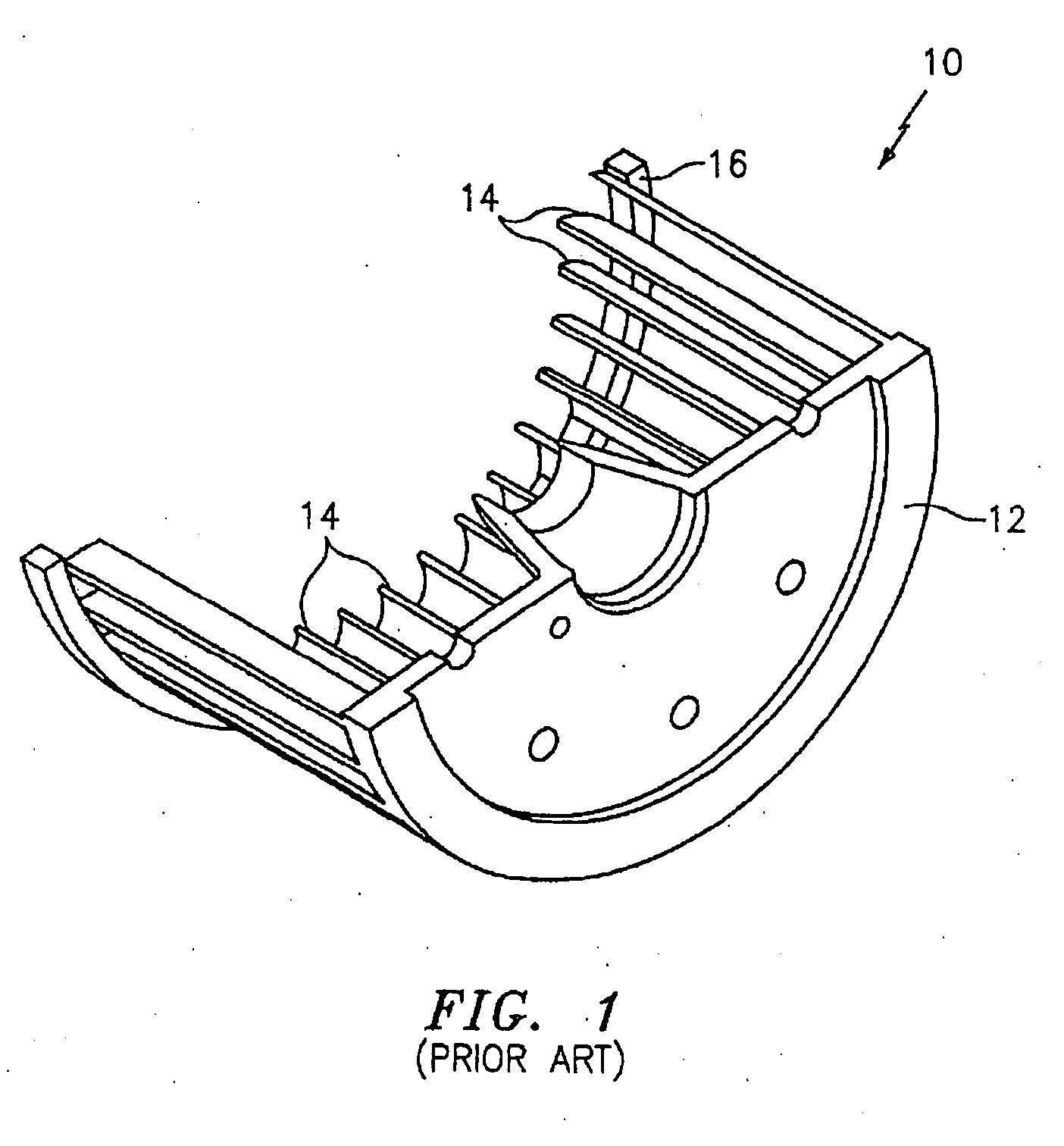

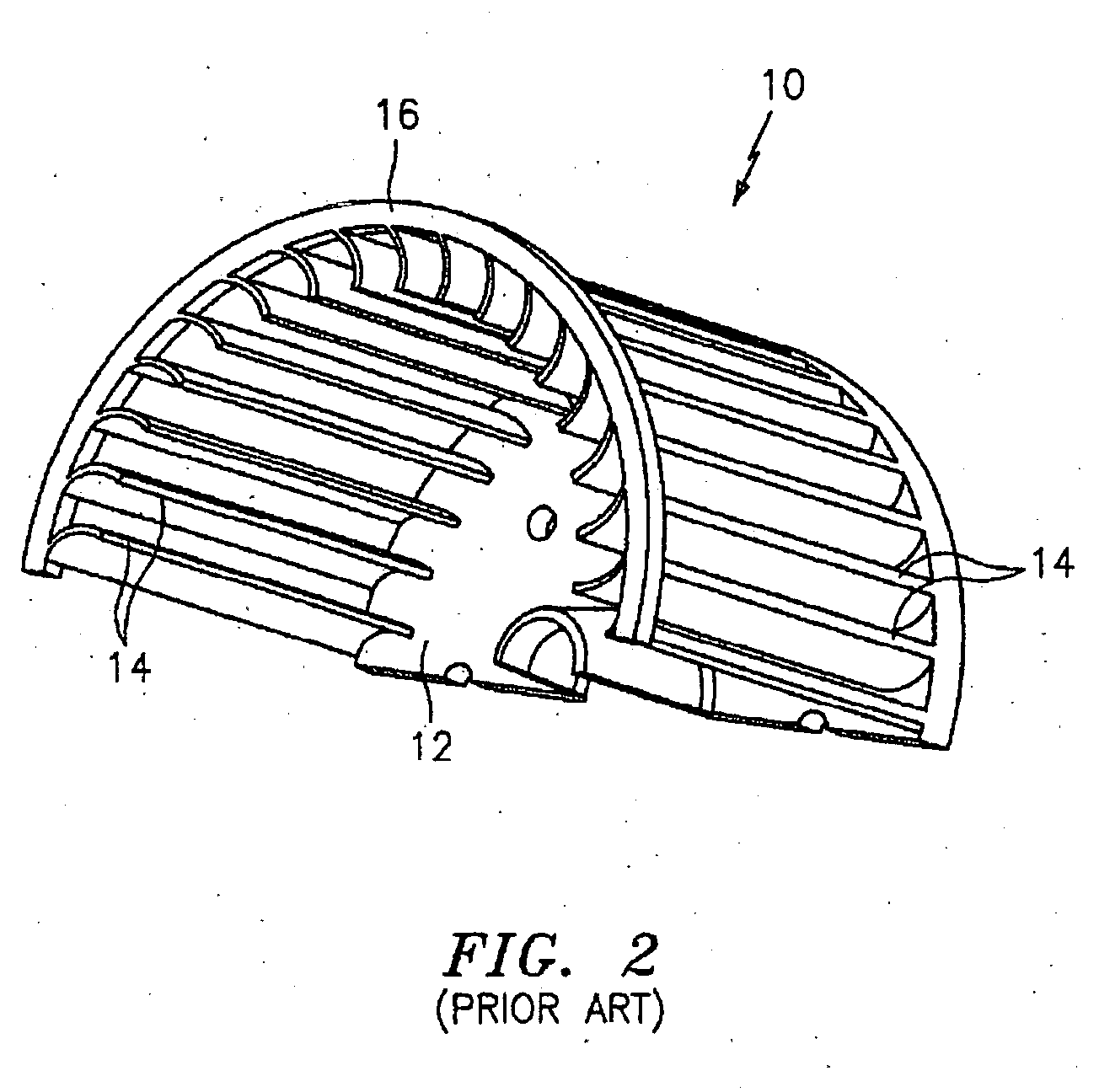

[0013] Referring initially to FIGS. 1 and 2, a prior art impeller indicated generally at 10 has a back plate 12, a plurality of circumaxially arranged air moving blades 14,14 integral with the back plate 12, and an end ring 16 integral with the blades at an end thereof opposite the back plate. The outer diameter of the back plate coincides with that of the blades and the inner diameter of the end ring coincides with the outer diameter of the blades. Thus, it will be apparent that the cavity of the mold forms only the inlet ring and the core of the mold forms the back plate and blades. It will also be apparent that the shut off and parting line must reside along the outer edges of the blades the aforementioned attendant disadvantages being encountered.

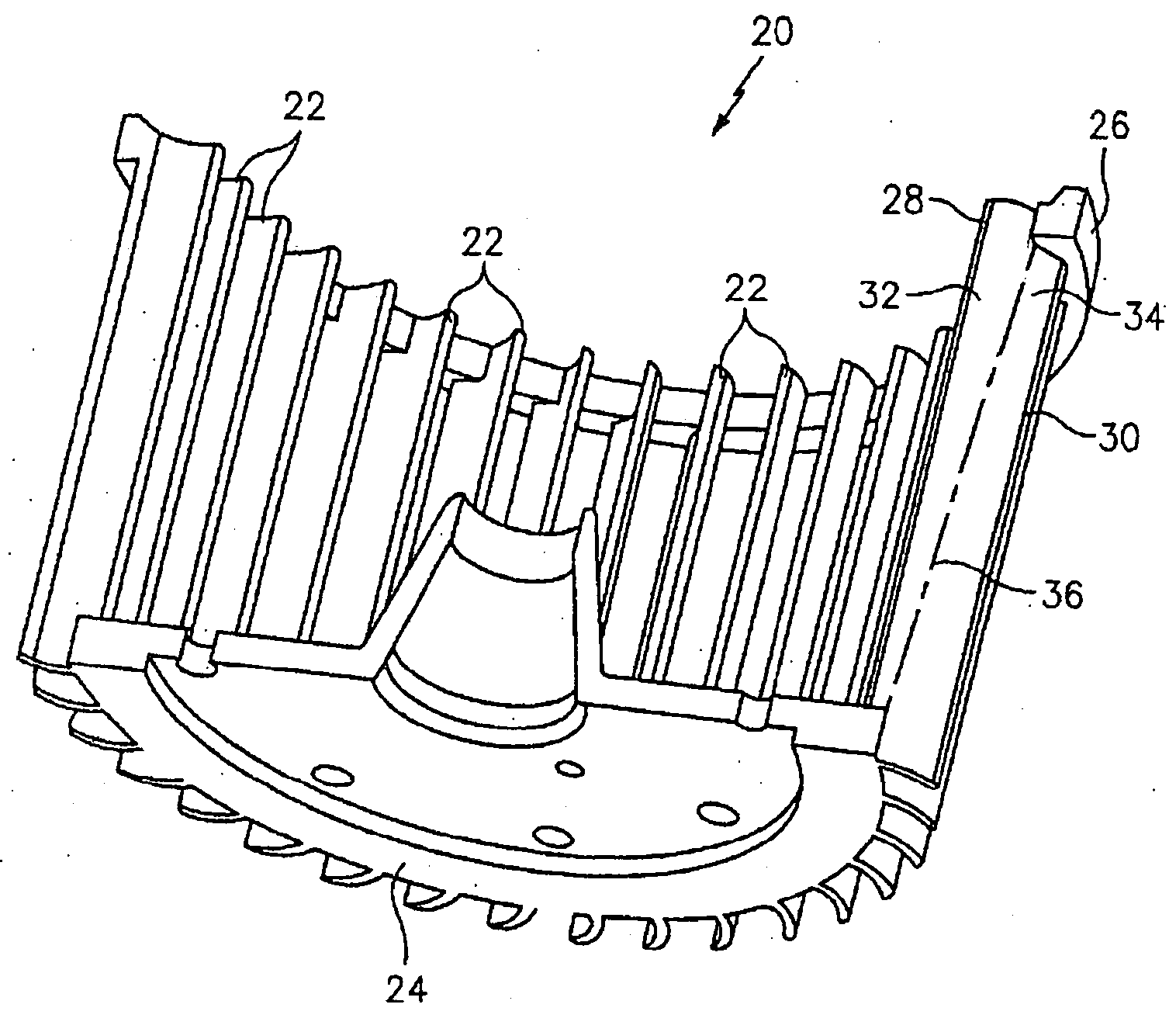

[0014] The improved impeller shown in FIG. 3 at 20 has a plurality of blades 22,22, a back plate 24, and an end ring 26. Each blade 22 has inner and outer edges 28 and 30 and adjacent inner and outer elongated portions 32 and 34 which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com