Closing Method and Closing Machine

a technology of closing machine and closing method, which is applied in the direction of manufacturing tools, shaping tools, other domestic objects, etc., can solve the problems of reducing poor wear resistance of the die, and achieves the effects of improving production efficiency, high wear resistance, and greatly prolonging the life of the di

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]This invention will now be described in further detail with reference to the attached drawings.

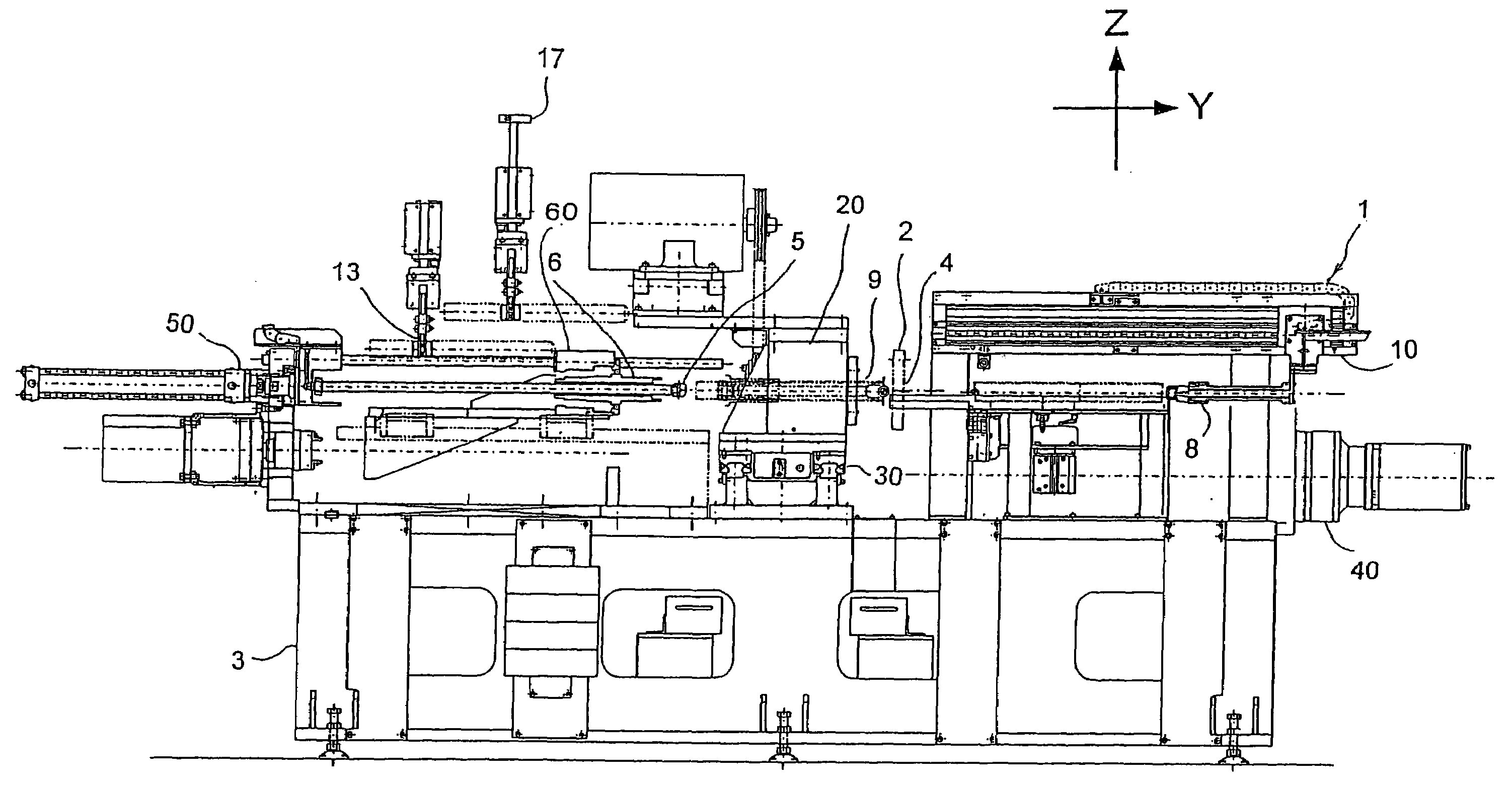

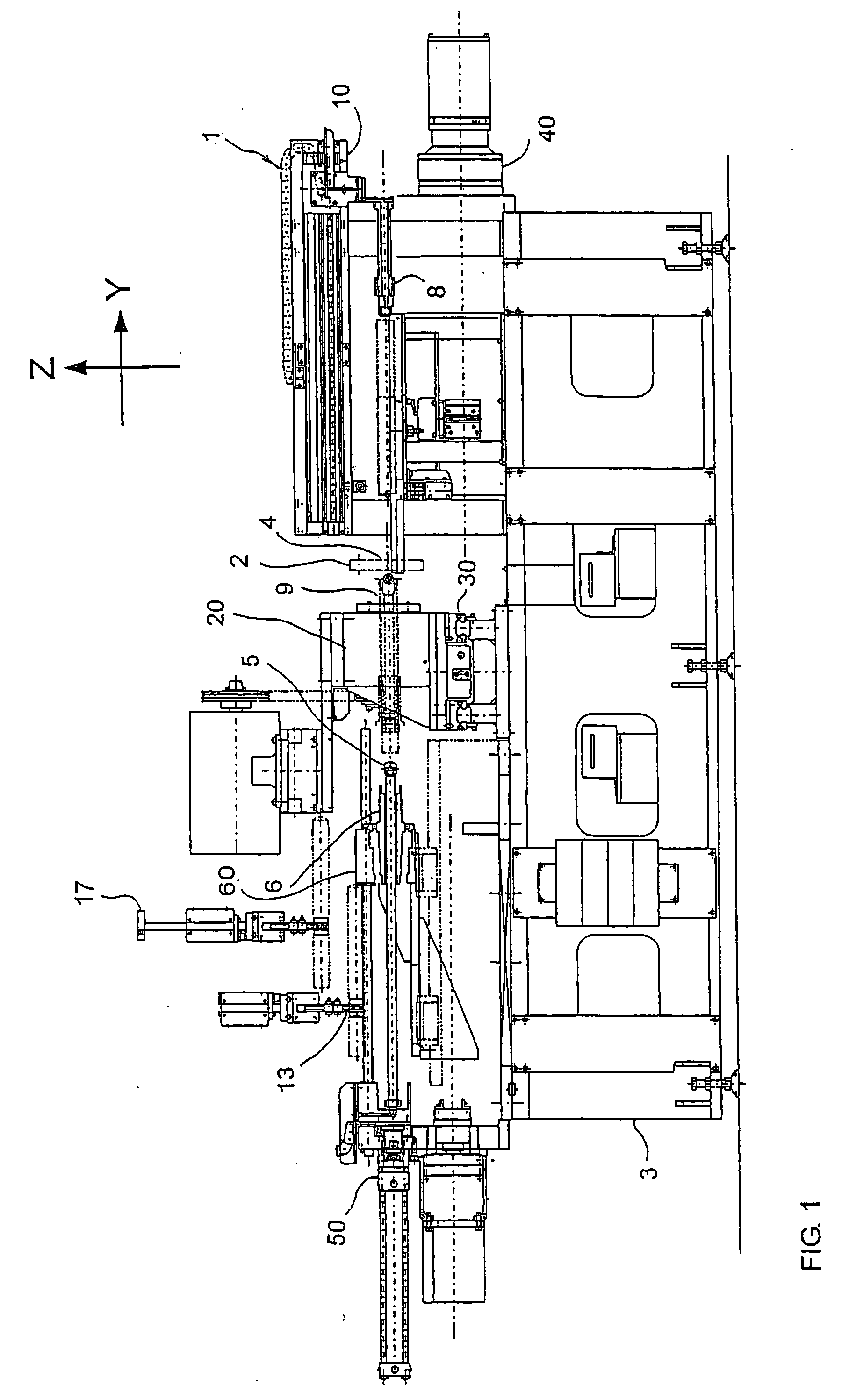

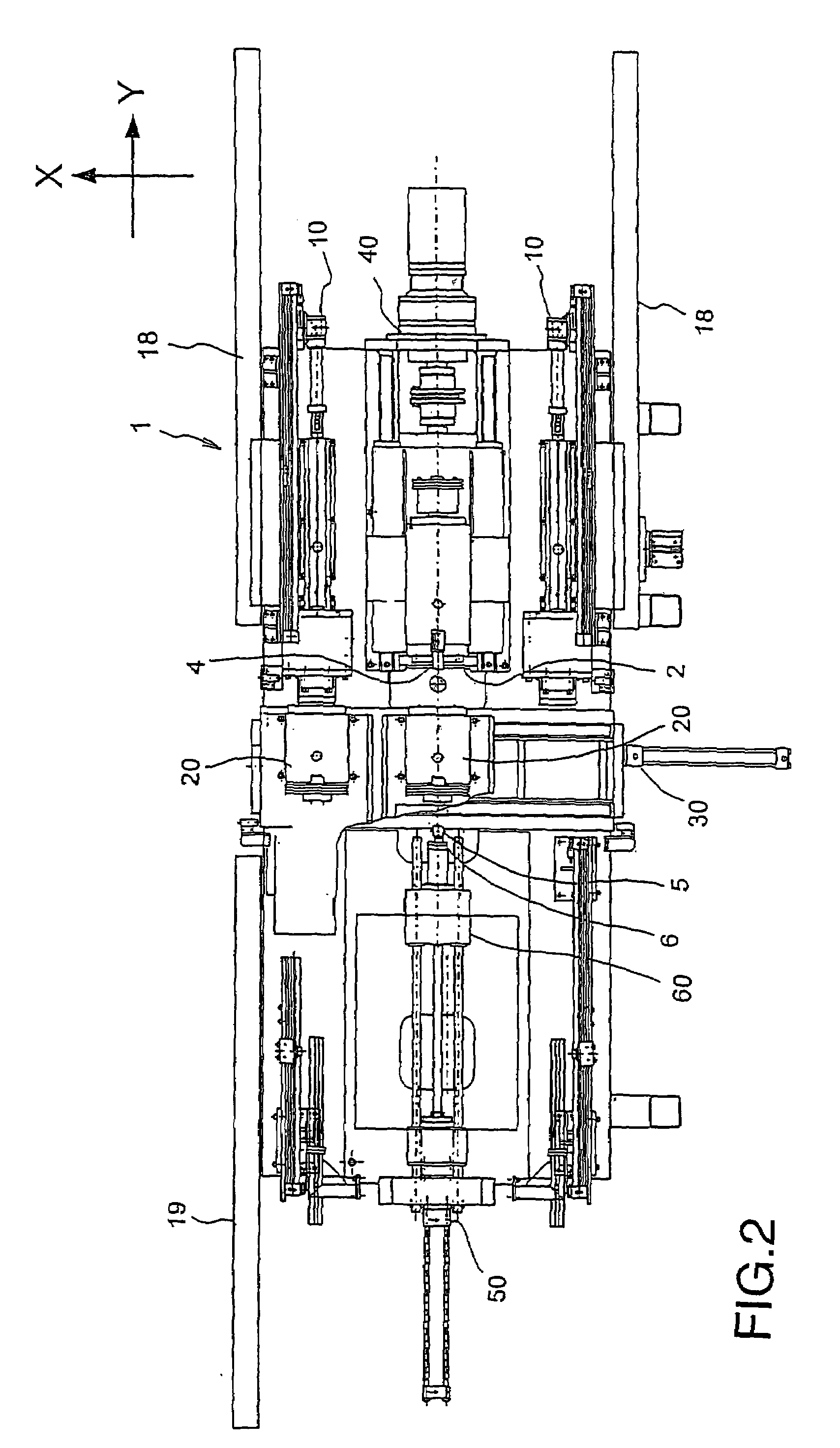

[0017]FIGS. 1 to 3 show the overall constitution of a closing machine 1. In FIGS. 1 to 3, three axes, namely X, Y, and Z, are set orthogonal to each other. It is assumed that the X axis extends in a substantially horizontal lateral direction, the Y axis extends in a substantially horizontal front-rear direction, and the Z axis extends in a substantially vertical direction. The overall constitution of the closing machine 1 will now be described.

[0018]Two chuck spindles 20 which drive a work piece 9 to rotate about its axial center, and a single die driving device 40 which drives a die 4, are provided in a central portion of the closing machine 1. The chuck spindles 20 perform a reciprocating motion in the X axis direction relative to a pedestal 3 via a chuck spindle moving device 30, to be described later, thereby moving alternately to the central portion of the closing machine 1 so a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com