Double-post inclined type multi-pull-rod prestress machine frame of free forging hydrostatic press

A hydraulic press, prestressing technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machines, manufacturing tools, etc. Problems such as poor process adaptability, to achieve the effect of reducing the weight of the equipment, making full use of the working area and height space, and improving the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

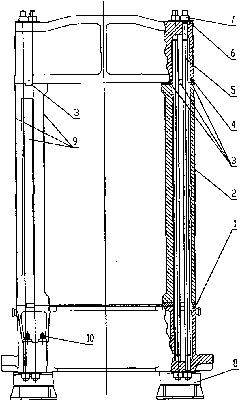

[0022] like figure 1 As shown, a double-column inclined multi-tie rod prestressed frame of a free forging hydraulic press is mainly composed of a lower beam 1, two hollow rectangular columns 2, an upper beam 4 and a high-strength tie rod 5 placed in the hollow rectangular column and preloaded. Nut 7 composition. There are two hollow rectangular columns 2, and high-strength tie rods 5 are placed in the two hollow rectangular columns 2, and pass through the upper beam 4 and the lower beam 1, the upper beam 4 and the hollow rectangular column. 2, between the lower beam 1 and the hollow rectangular column 2, the upper beam 4 and the lower beam 1 and the two hollow rectangular columns 2 are firmly fixed by 4 groups of 16 rectangular positioning keys 3 arranged in a cross shape. mosaic together.

[0023] According to the pre-tightening force and pre-tightening method specified in the design, the pre-tightening force is generated over the entire length of the high-strength tie rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com