Segmental lining reinforcing type combined supporting structure

A combined support and reinforced technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve problems such as water leakage, insufficient rigidity and deformation of fabricated segment lining support, and segment misalignment, etc., to achieve Control the deformation of surrounding rock, fast and convenient installation, and improve the effect of mechanical behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

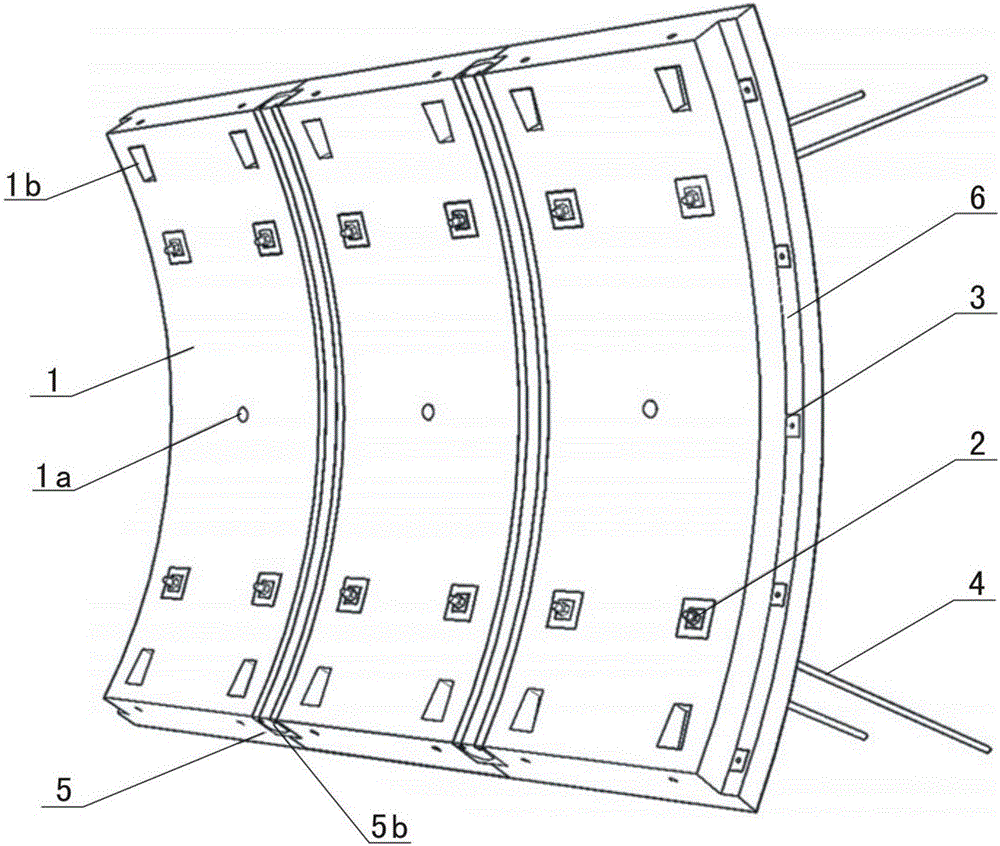

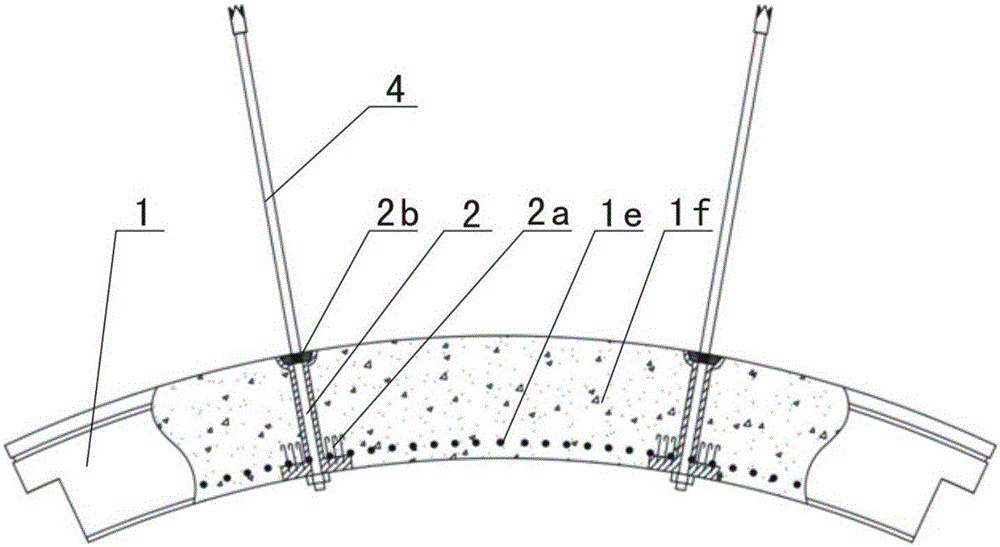

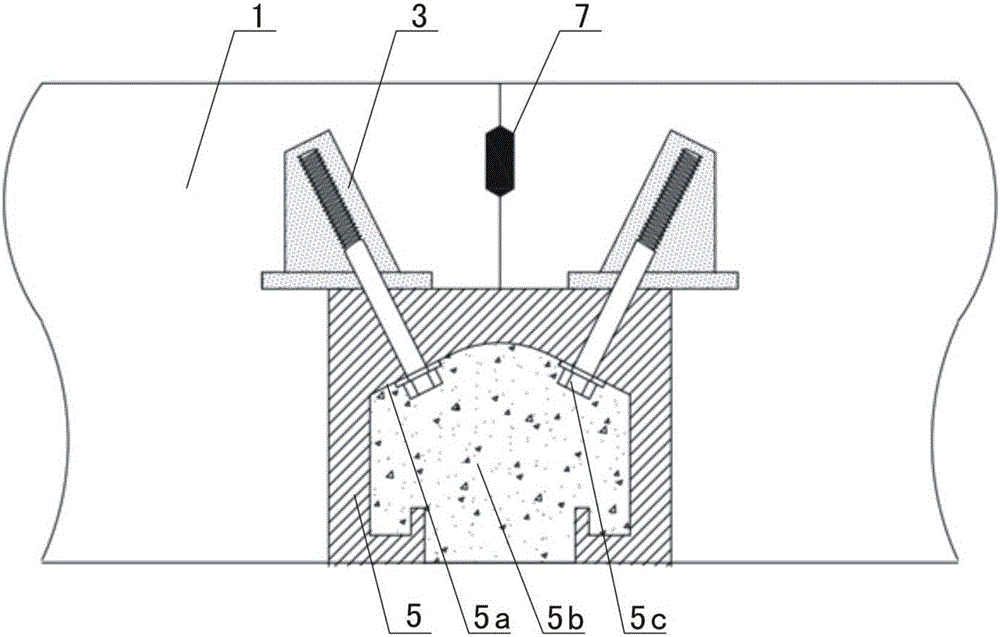

[0024] Such as figure 1 , figure 2 and image 3 As shown, the segment lining reinforced combined support structure of the present invention includes a segment 1 made of steel bars and concrete, an arched steel frame 5 equal to the inner diameter of the segment 1, and a self-advancing threaded anchor rod 4, the arched The radial section of the steel frame 5 is "C" shape, and the two sides of the segment 1 are respectively provided with installation grooves 6, and the bottom of the corresponding installation groove 6 is provided with a pre-embedded bolt connector 3 in the segment 1, The arched steel frame 5 is installed in the installation groove 6 of two adjacent segments 1 and fixedly connected with the two adjacent segments 1, and a waterproof rubber strip is provided between the two side edges of the adjacent segments 1 7. The outer opening of the arched steel frame 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com