Automobile water tank upper beam made of carbon fiber composite materials and manufacturing method thereof

A water tank upper beam and composite material technology, which is applied in the field of carbon fiber composite automobile water tank upper beam and its production, can solve problems such as unreasonable reinforcement structure design, cracking in stress concentration areas, uneven rigidity of water tank beams, etc., so as to facilitate one-time processing and molding , to meet the effect of high strength and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

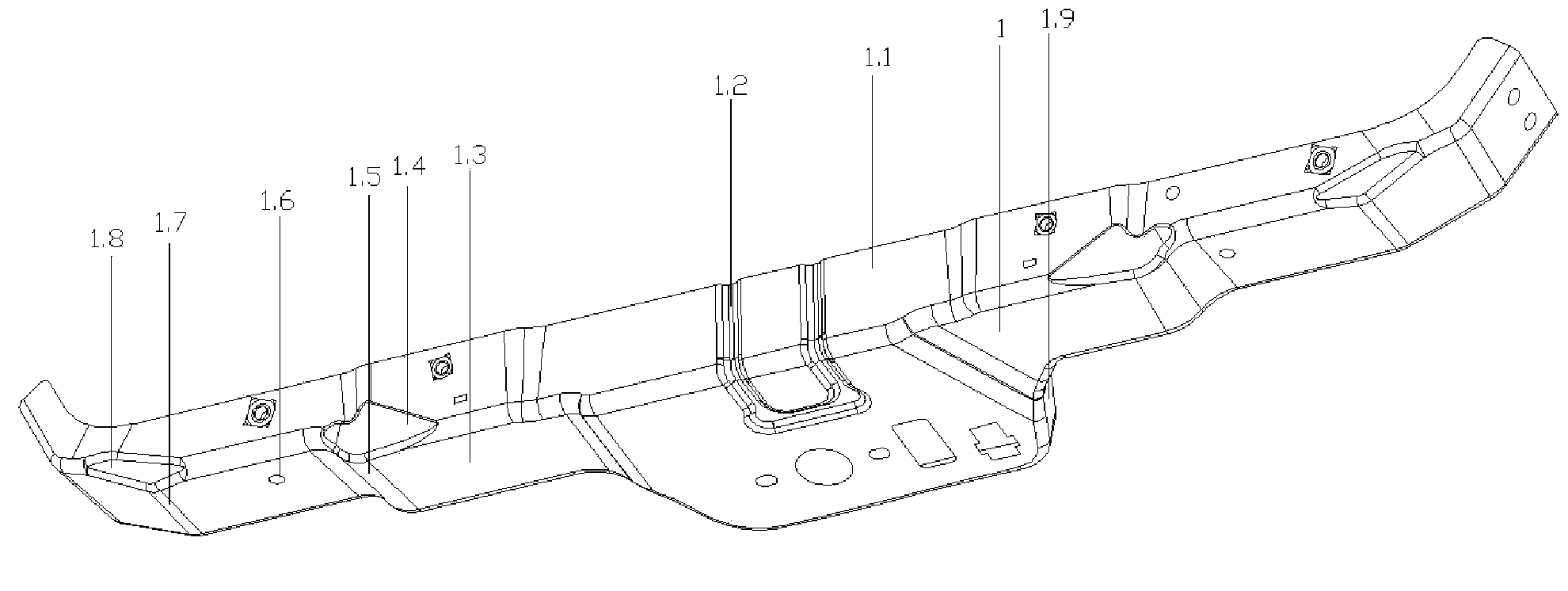

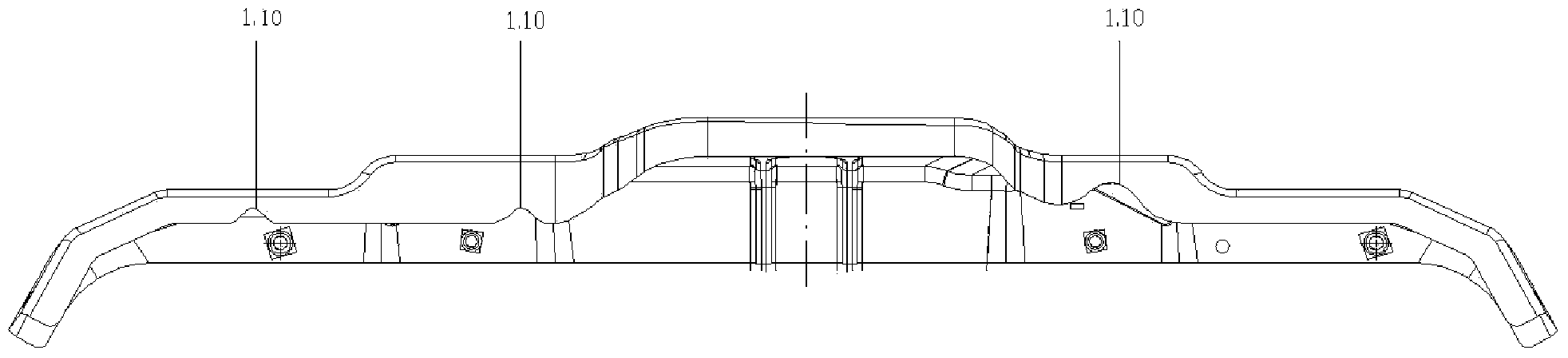

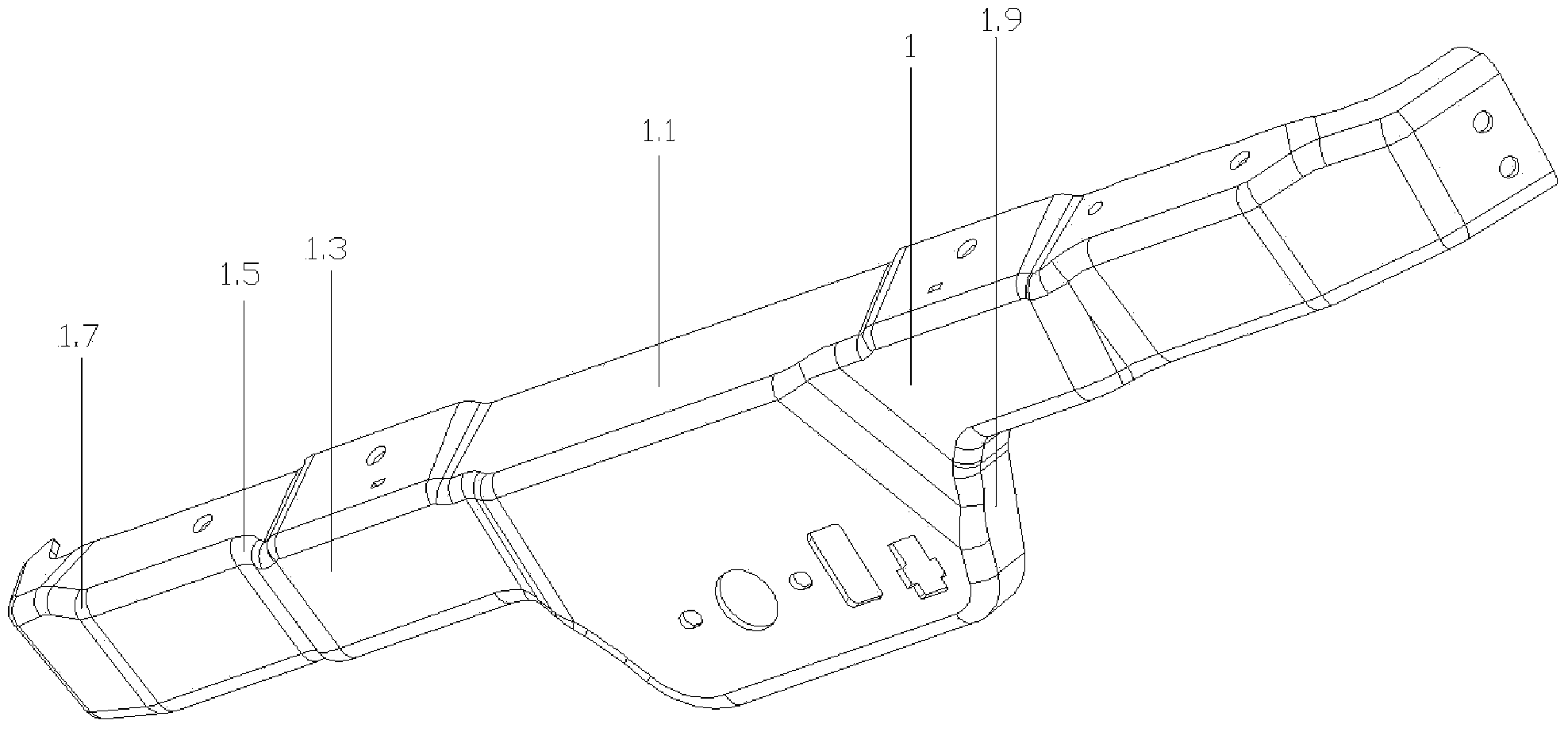

[0043] see image 3 , Figure 4 As shown, the embodiment of the present invention provides a carbon fiber composite automobile water tank upper beam, and the structure of the water tank upper beam is optimized. Specifically, the water tank upper beam 1 structure at least includes: beam body 1.1, beam wing 1.3, the second One wing 1.5, second wing 1.7, side 1.9, beam crown 1.11; the selected material is carbon fiber T300+5028 resin composite material, the thickness is about 3.0mm, and the weight is about 0.4kg; the carbon fiber (CF) is a fiber Shaped carbon material, with a carbon content of more than 90%, not only has the inherent characteristics of carbon materials, but also has the softness and processability of textile fibers, and has corrosion resistance, good heat resistance, light weight, high strength, and high elastic modulus. High density, low density and very excellent mechanical properties, depending on the fiber grade and orientation, it can even reach the strengt...

Embodiment 2

[0046] In order to realize the above-mentioned structural design, an embodiment of the present invention provides a method for manufacturing an upper crossbeam of an automobile radiator made of carbon fiber composite material. Specifically, preferably, the manufacturing method at least includes: 1) material selection; 2) layer laying; 3) sealing; 4) vacuuming; 5) resin introduction; 6) process steps such as curing and demoulding;

[0047] Step 1) material selection;

[0048] The carbon fiber composite material is composed of multi-layer carbon fiber material as a reinforcement and resin as a matrix. The multi-layer carbon fiber material is selected from Toray T300 carbon fiber fabric in Japan. The resin is selected from a medium-low temperature rapid curing 5028 epoxy resin system. Raw materials, wherein the content of carbon fiber fabric (weight percentage, the same below) is 50-60%, and the content of epoxy resin material is 40-50%;

[0049] The manufacturing method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com