Improved soft rock roadway integral tunneling protection support

An improved, soft rock technology, used in pillars/supports, mining equipment, earthwork drilling, etc., can solve problems such as limitations and unreliable stability, achieve high installation efficiency, control the amount of roadway deformation, and comprehensive support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the present invention will be further described in detail with reference to the embodiments and drawings, but the implementation of the present invention is not limited thereto.

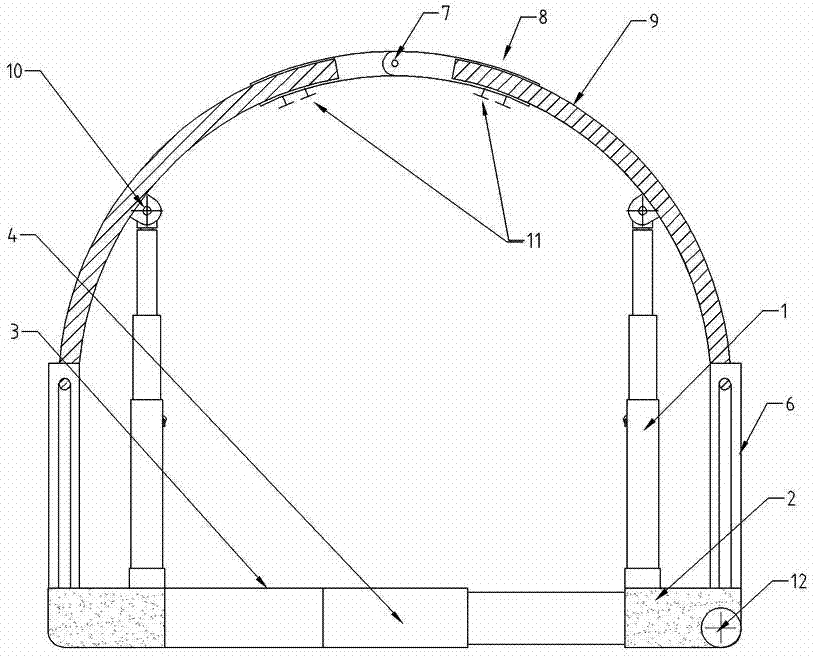

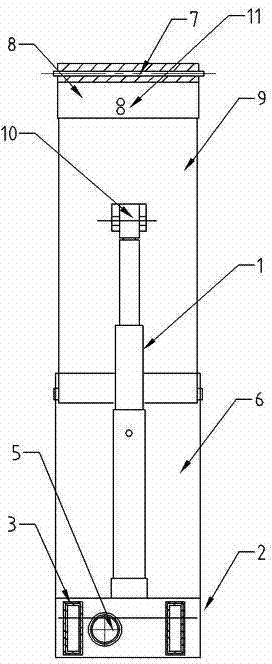

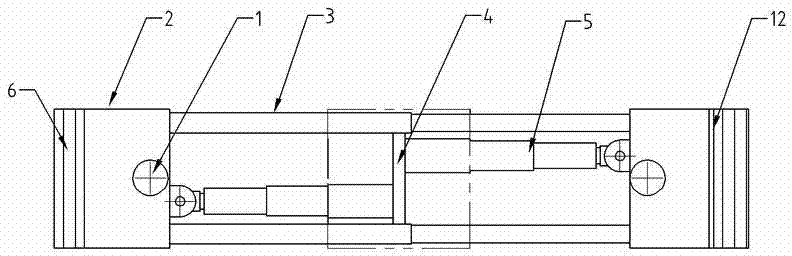

[0018] figure 1 Shows an improved soft rock roadway integral excavation and protection support, which is mainly composed of a semicircular arch protection, two left and right hydraulic support columns 1 and a support base; the overall cross section of the support base is in the shape of "U" or flat bottom "U" "Shape, the bracket base is formed by connecting two left and right column fixing seats 2 and two sets of parallel telescopic guide rails 3, of which two sets of parallel telescopic guide rails 3 are arranged between the two left and right column fixing seats 2; The middle part between the parallel telescopic guide rails 3 is provided with a fixed seat 4 that connects the two telescopic guide rails transversely, and two side push cylinders 5 facing opposite to the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com