A foldable parallel mechanism and its application

A parallel and driving motor technology, applied in the aerospace field, can solve the problems of limited working space, inability to guarantee processing, poor precision, etc., and achieve the effects of good stretchability and compression performance, reduced space occupation, and large folding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings, from which those skilled in the art can clearly understand the present application and be able to implement the present application. Without departing from the principles of the present application, the features of the various embodiments may be combined to obtain new embodiments, or instead of certain features of certain embodiments, to obtain other preferred embodiments.

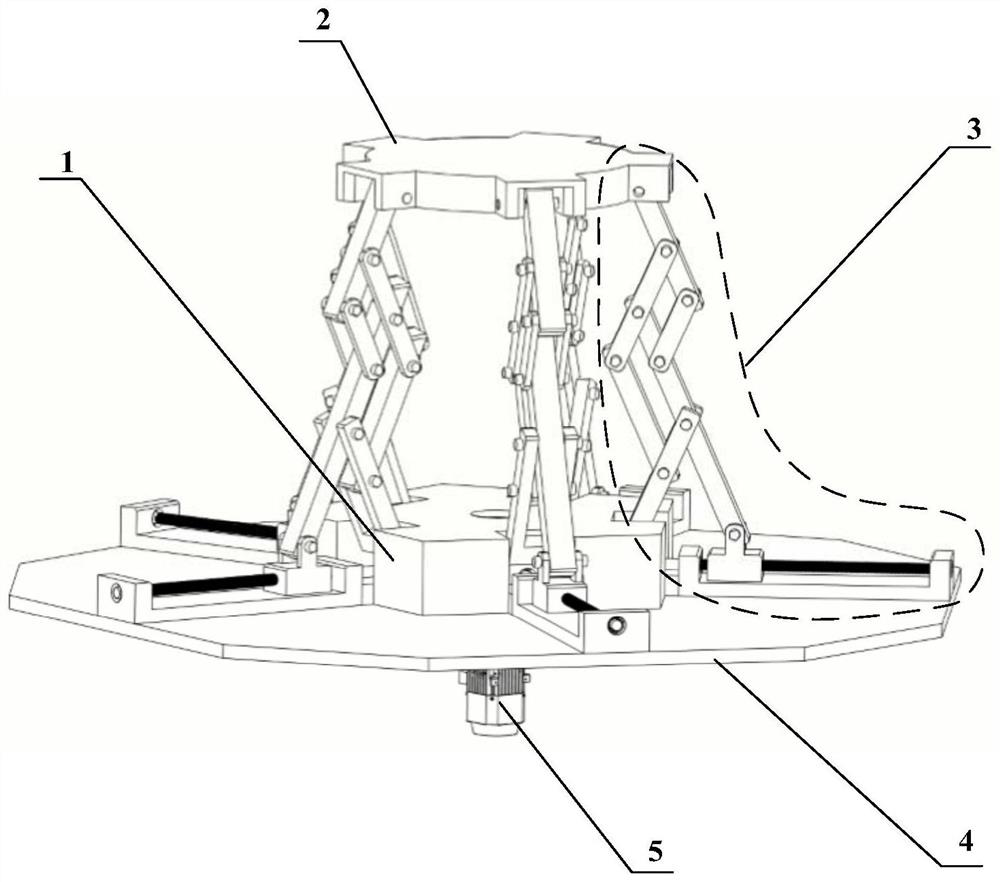

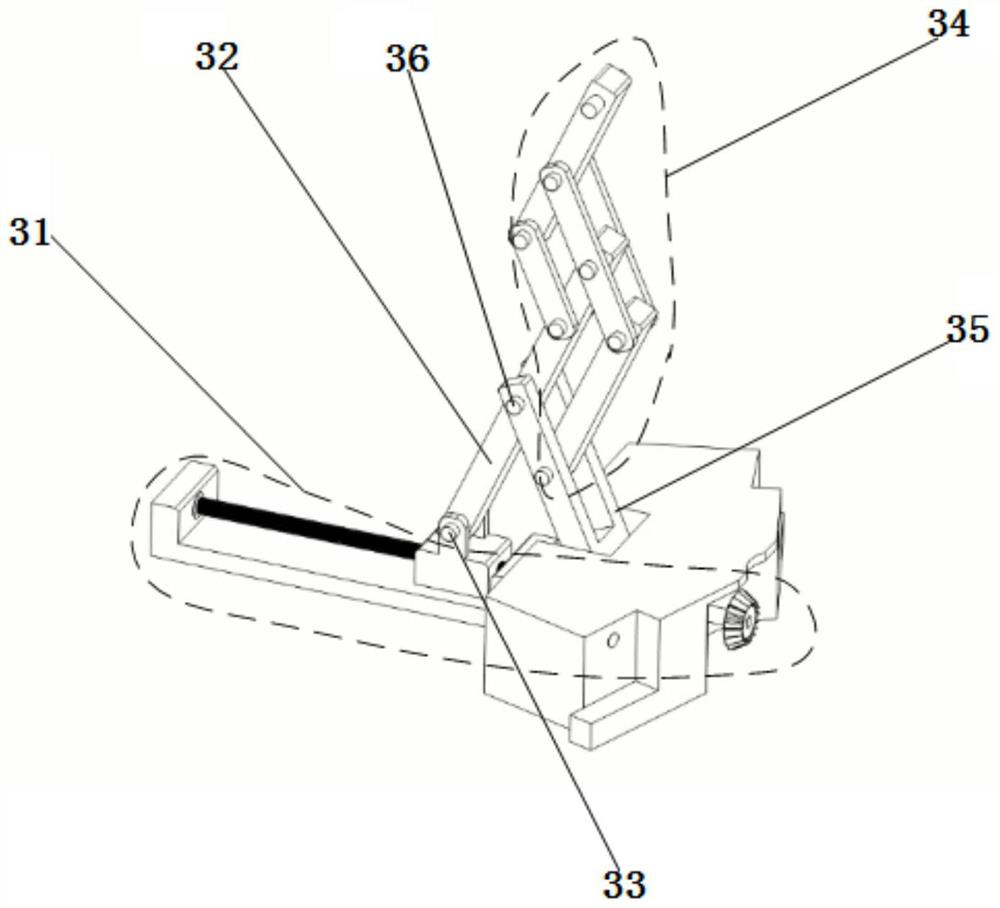

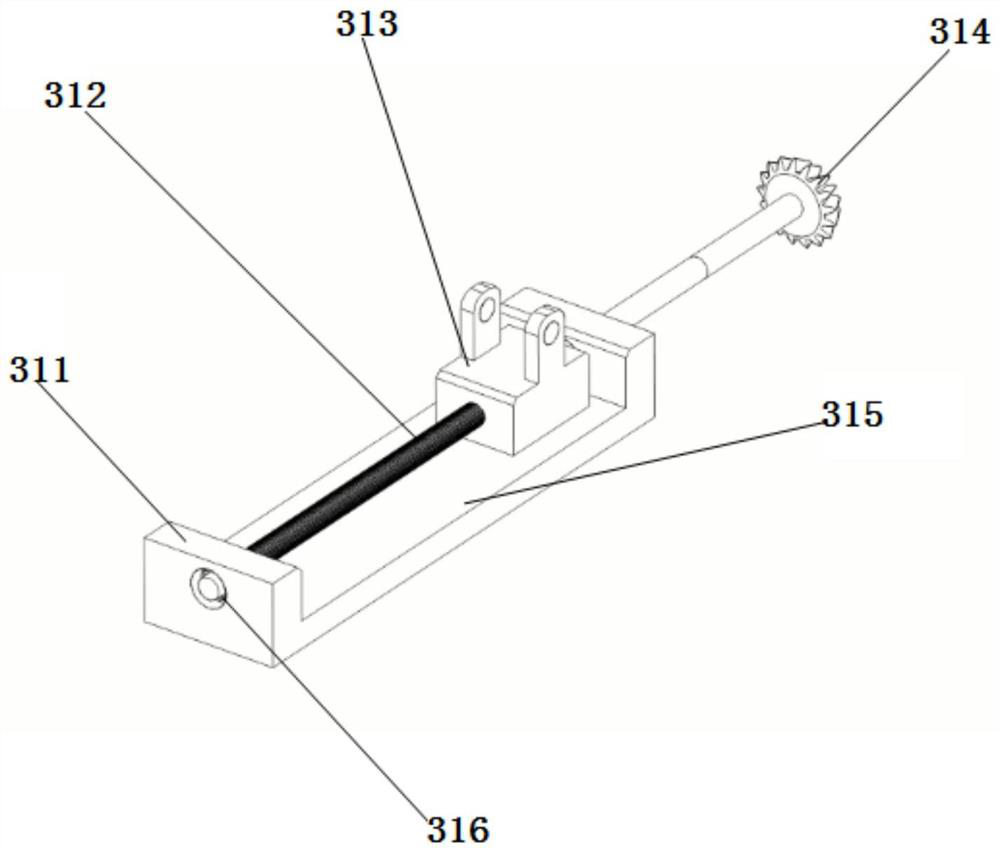

[0036] see Figures 1 to 6, the application provides a foldable parallel mechanism, including a base 1, the base 1 is connected with one end of the scissor-type extension chain 3, and the other end of the scissor-type extension chain 3 is connected with the moving platform 2, The scissor-type extension chain 3 is connected with the drive motor assembly 5; the scissor-type extension chain 3 includes a chain drive assembly 31, which is connected to one end of the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com