A method of eliminating deformation of a wax mould for an ultrathin elongated working blade of a turbine

A wax model and working technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of blade wax model deformation, etc., and achieve the effects of improving the pass rate of precision casting, saving production costs, and reducing scrap rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

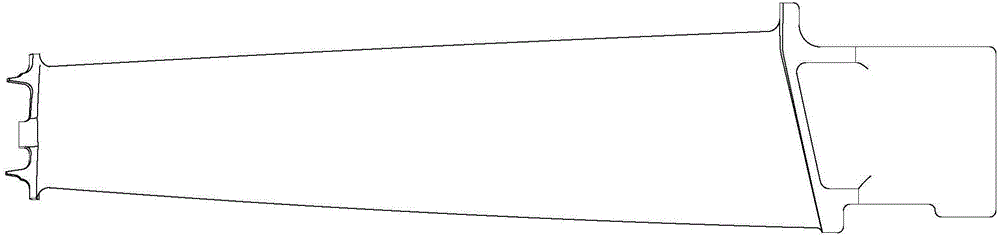

[0031] In this embodiment, the blade body length of the turbine working blade that needs to be developed and produced is 190mm, the blade body chord width is 25mm, and the thickness of the inlet and outlet edges of the blade is 0.5-0.6mm. Among them, the airfoil parameters of the blade wax model and The turbine working blades are the same.

[0032] The method for eliminating the deformation of the ultra-thin and slender turbine working blade wax model comprises the following steps:

[0033] Step 1: Design the wax mold mold according to the parameters of the blade back shape of the turbine working blade;

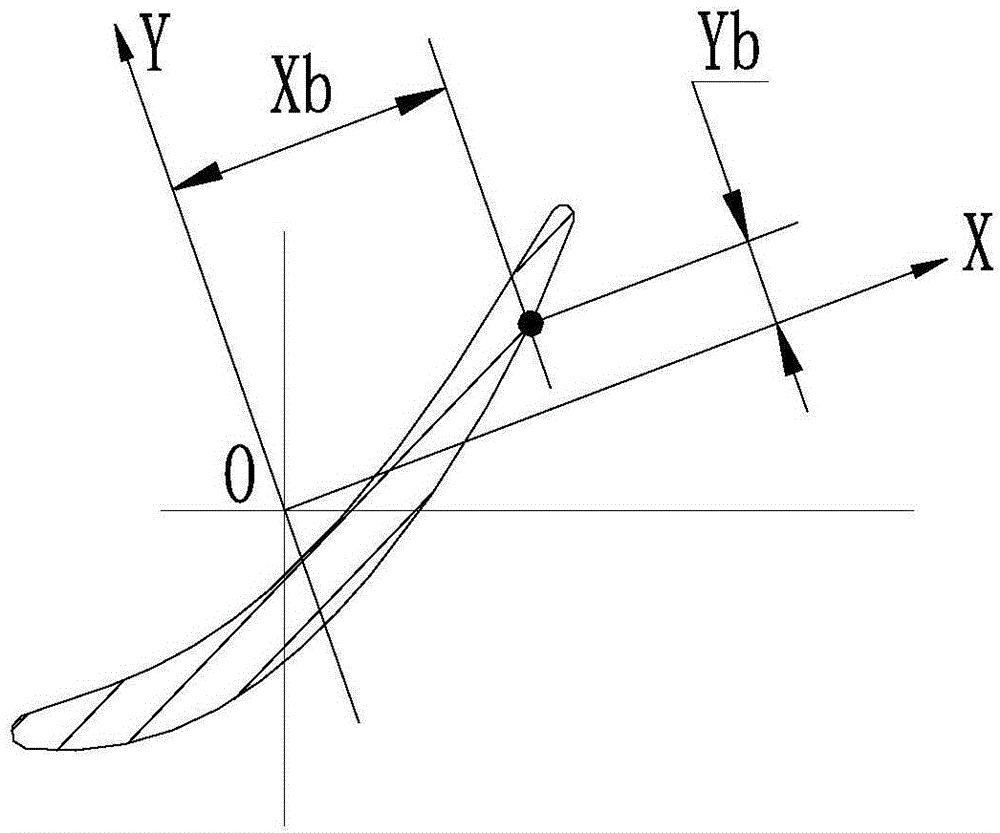

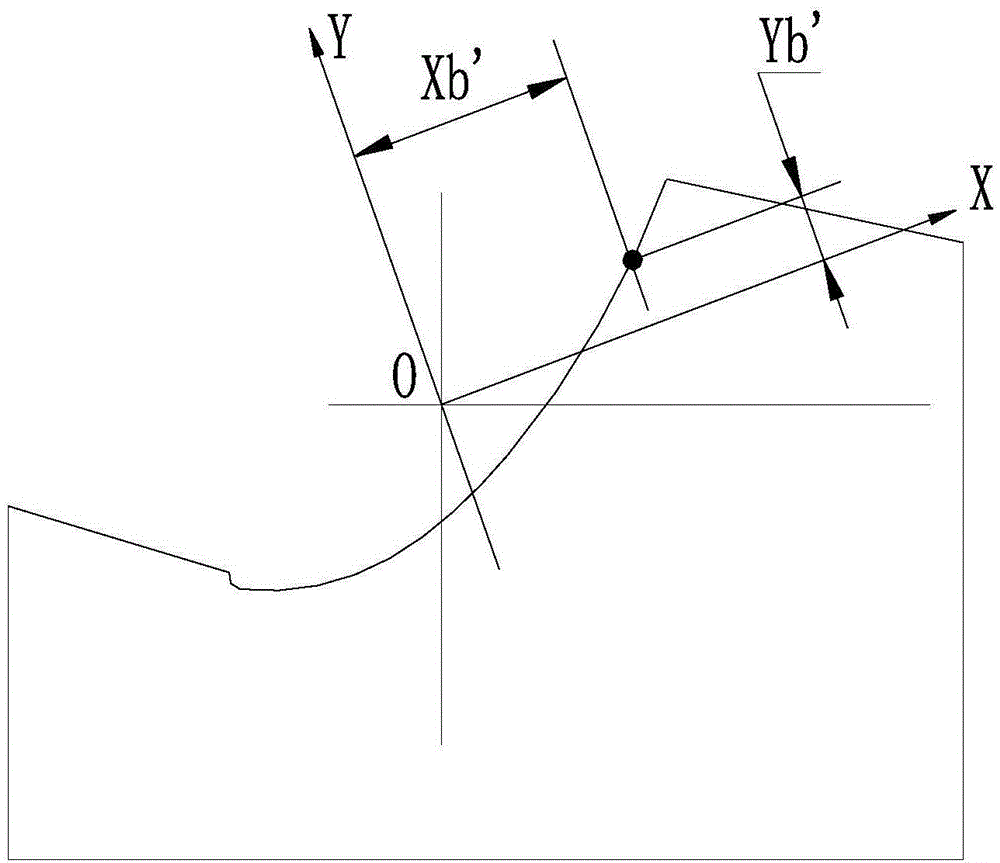

[0034] Step 2: According to the theoretical coordinate value of the blade back surface of the turbine working blade, calculate the coordinate value of the working surface of the wax mold, and the calculation formula is:

[0035] Xb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com