Shield construction method for three-line parallel under-passing trunk railway tunnel

A construction method and shield technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as ground surface and railway main line settlement overrun, increased difficulty of tunnel construction, train hazards, etc., to ensure the quality of project construction, good Economic benefits, the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

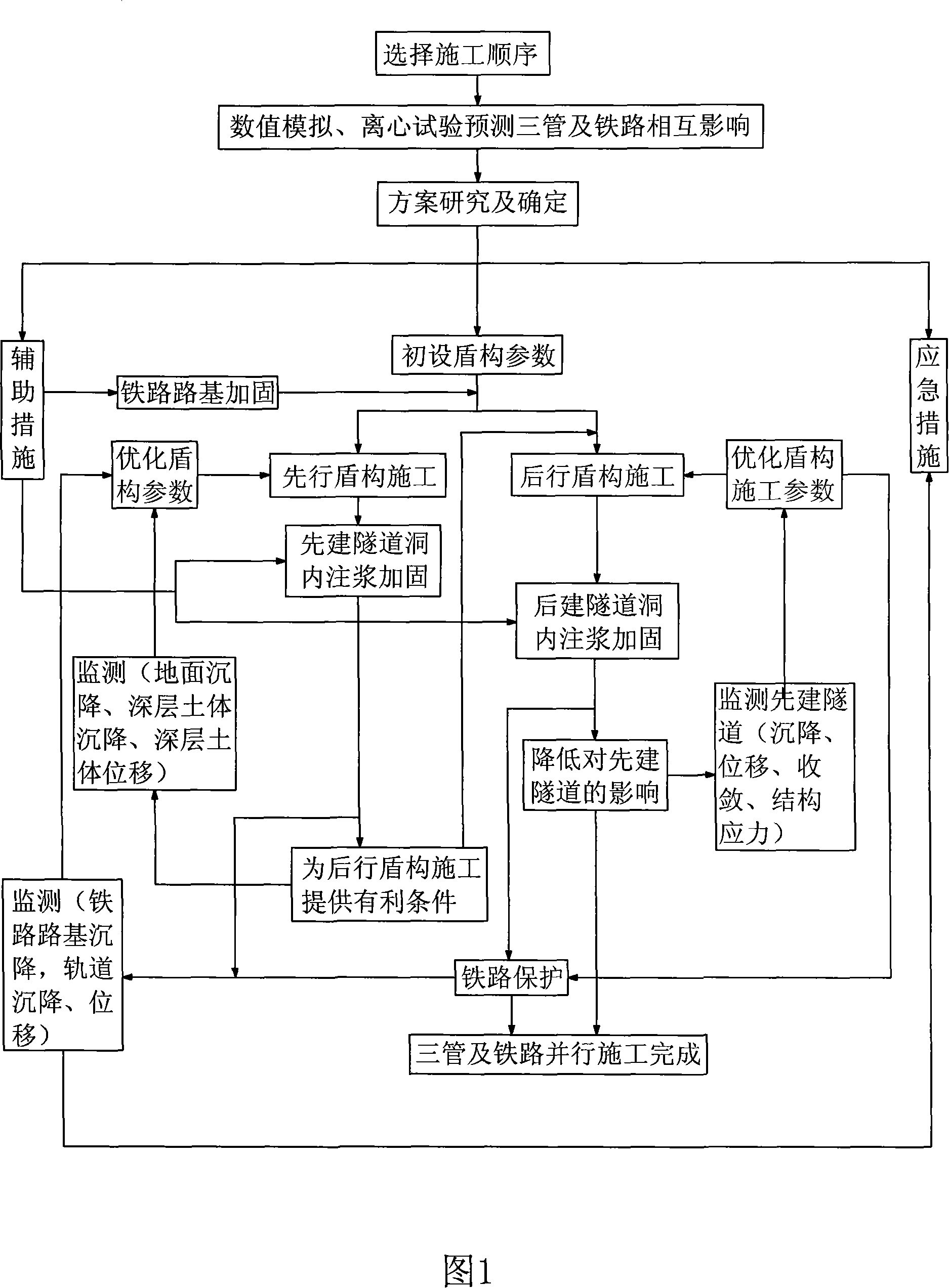

Image

Examples

Embodiment 1

[0035] The three-dimensional finite element is used to simulate each construction sequence and method. The software used is the large-scale finite element general software ANSYS, and the self-gravity stress field is taken as the initial stress field. The expression of the excavation simulation matrix is:

[0036] {[K i-1 ]+[ΔK i ]}{Δδ i}={ΔF ir}+{ΔF ia}(i=1, M), where M is the total number of construction stages, [K i-1 ] is the stiffness matrix after step i-1, [ΔK i ] is the increment or decrement of the soil and structure stiffness during the i-th construction process; {ΔF ir} is the boundary incremental nodal force array generated by excavation release; {ΔF ia} is the array of node forces added during construction. The D-P model is used for calculation, the calculation range is 100m horizontally, 50m vertically, the top is taken from the ground surface, and 72m along the tunnel axis. In the calculation, elastic shell elements are used for segments, and isoparametric...

Embodiment 2

[0045] The method of numerical simulation and centrifugal test is used to determine the detailed foundation reinforcement scheme and specific auxiliary construction method construction, to clarify the items and frequency of monitoring and measurement, and to comprehensively control and optimize the shield construction parameters.

[0046] The loss in shield tunneling is simulated by water injection and discharge method, and the surface settlement of three-hole shield tunnel under the condition of ground reinforcement and non-reinforcement condition is studied by centrifugal simulation test. The test is divided into two groups, one group is unreinforced stratum, which is undisturbed soil, and the other group is reinforced stratum. The reinforcement range is a rectangular parallelepiped stratum from the left, right and bottom of the tunnel to the surface. The reinforced stratum is made of 425 ordinary Portland cement and The formation is mixed, and the cement content is 10%. Put...

Embodiment 3

[0051] Take the shield construction of a three-line parallel tunnel passing through the tunnel area of the two-way main railway line as an example: the three-line parallel section of the project passes under the double-line main line railway with a subgrade width of about 12m. Orthogonal. The shield construction method of the three-line parallel tunnel crossing the double-line railway trunk line is as follows:

[0052] (1) Select the earth pressure balance shield machine with hinges, and advance sequentially according to the plan of constructing the tunnels on both sides one by one, and then constructing the middle tunnel. The construction interval of the third-line tunnel should be long to avoid superposition of impacts between tunnels.

[0053] (2) Before the construction of the third-line shield tunnel passing under the railway, two rows of 4.2m thick rotary grouting piles are installed on both sides of the railway line in the underpassing area. The area between the jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com