Pit supporting system and installation method

A technology of support system and installation method, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of low installation accuracy, difficult construction, labor and time consuming, etc., to improve project quality, speed up foundation pit construction, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

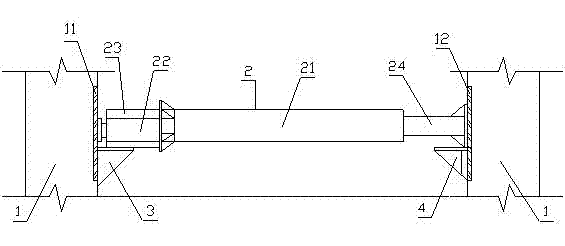

[0025] figure 1 It is a structural schematic diagram of Embodiment 1 of the foundation pit support system of the present invention, please refer to figure 1 , a foundation pit support system, comprising a telescopic steel support 2 including a steel pipe support 21 and a seat box 23, the seat box 23 is installed on one end of the steel support 21, one side of the seat box 23 is open, the support The opening side of the seat box 23 is located on the side opposite to the connecting part of the steel pipe support 21 and the support box 23, a jack 22 is placed in the support box 23, and the top of the piston of the jack 22 is exposed to the opening side, and is offset against the first steel plate 11 , the bottom of the jack 22 abuts against the connection part, and a jack 22 is installed in the support box 23 so that the length of the telescopic steel support 2 can be adjusted by operating the jack 22, and the other side of the steel pipe support 21 is connected to a joint 24 , ...

Embodiment ( 2

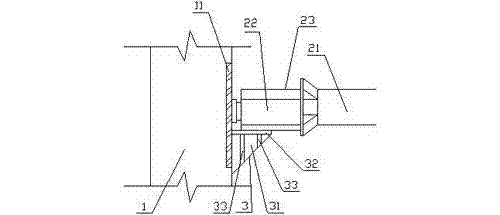

[0029] figure 2 It is a structural schematic diagram of the first support of the foundation pit support system of the present invention, please refer to figure 2 , on the basis of the above-mentioned embodiments, the first support 3 of the foundation pit support system of the present invention is specifically a corbel support, comprising: two corbel rib plates 31 installed in parallel on the first steel plate 11, installed A plurality of beef hamstring side panels 33 on the sides of the two beef hamstring panels 31, the two beef hamstring panels 31 are perpendicular to the plate surface of the first steel plate 11, and the plurality of beef hamstring side panels 33 are perpendicular to the two cow hamstring panels 31 , two hamstring plates 31 are fixedly installed on the plate surface of the first steel plate 11 by welding, and a panel 32 is horizontally installed on two hamstring plates 31 and a plurality of hamstring side plates 33, and the bottom surface of the panel 32 ...

Embodiment ( 3

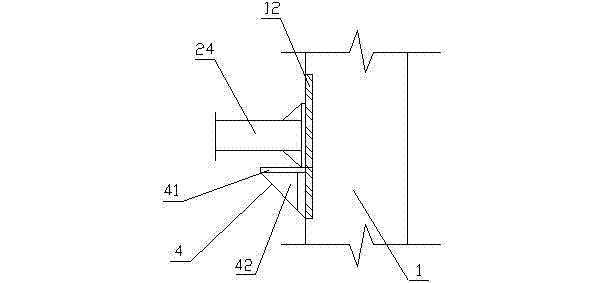

[0031] image 3 It is a structural schematic diagram of the second support of the foundation pit support system of the present invention, please refer to image 3, on the basis of the above embodiments, the second support 4 of the foundation pit support system of the present invention is specifically a steel box support, including: at least one triangular ribbed plate 42 is installed on the plate surface of the second steel plate 12, and the triangular The ribbed plate 42 is installed on the plate surface of the second steel plate 12 by welding, the triangular ribbed plate 42 can be a triangular steel plate, and the triangular ribbed plate 42 is fixed more firmly by welding, so that the triangular ribbed plate 42 can withstand upward and downward pressure, at least one triangular ribbed plate 42 is equipped with a shelf 41, and the triangular ribbed plate 42 is equipped with a shelf 41 to support the joint head sealing plate, and the joint joint 24 can be placed on the shelf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com