Ground stress release method for high ground stress soft rock tunnel positive step excavation

A technology of tunnel excavation and high ground stress, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of limited deformation control ability, large deformation, unreasonable drilling position design, etc., and achieve the effect of controlling the deformation of surrounding rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described with reference to the accompanying drawings and specific embodiments:

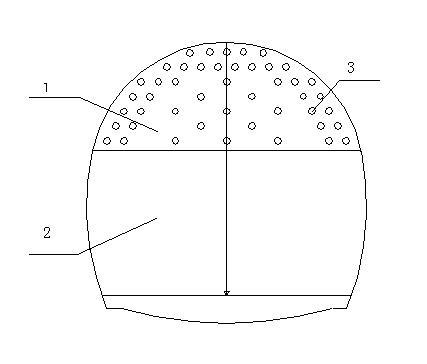

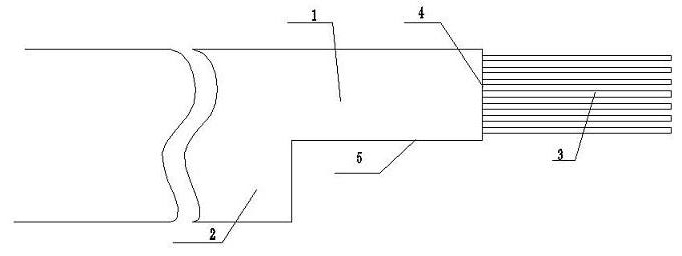

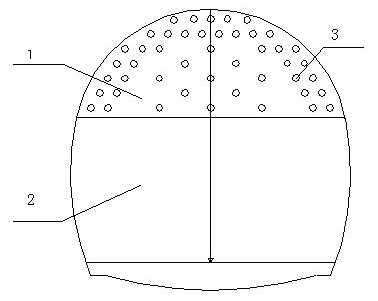

[0019] like figure 1 , figure 2 As shown in the figure, an in-situ stress release method for excavation of a high-in-situ stress soft rock tunnel by the positive step method, after the tunnel construction forms an upper step 1, several boreholes 3 are drilled in the direction of the tunnel excavation to make the in-situ stress Acting on these boreholes, the borehole consumes the energy of in-situ stress in the process of deformation, and releases the in-situ stress. The specific steps are as follows:

[0020] a. First excavate the upper part of the excavation surface to form the upper step 1, and then level the upper step 1 to provide a suitable working platform 5 for the drilling rig;

[0021] b. Carry out the steps of vertical arching, drilling bolts, and initial support of shotcrete on the upper step 1 to ensure the safety of the tunnel during drilling; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com