High-stress roadway surrounding rock deformation control method

A technology of surrounding rock deformation and control method, which is applied to earth cube drilling, mining equipment, mining equipment, etc., and can solve problems such as high cost and unsatisfactory support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

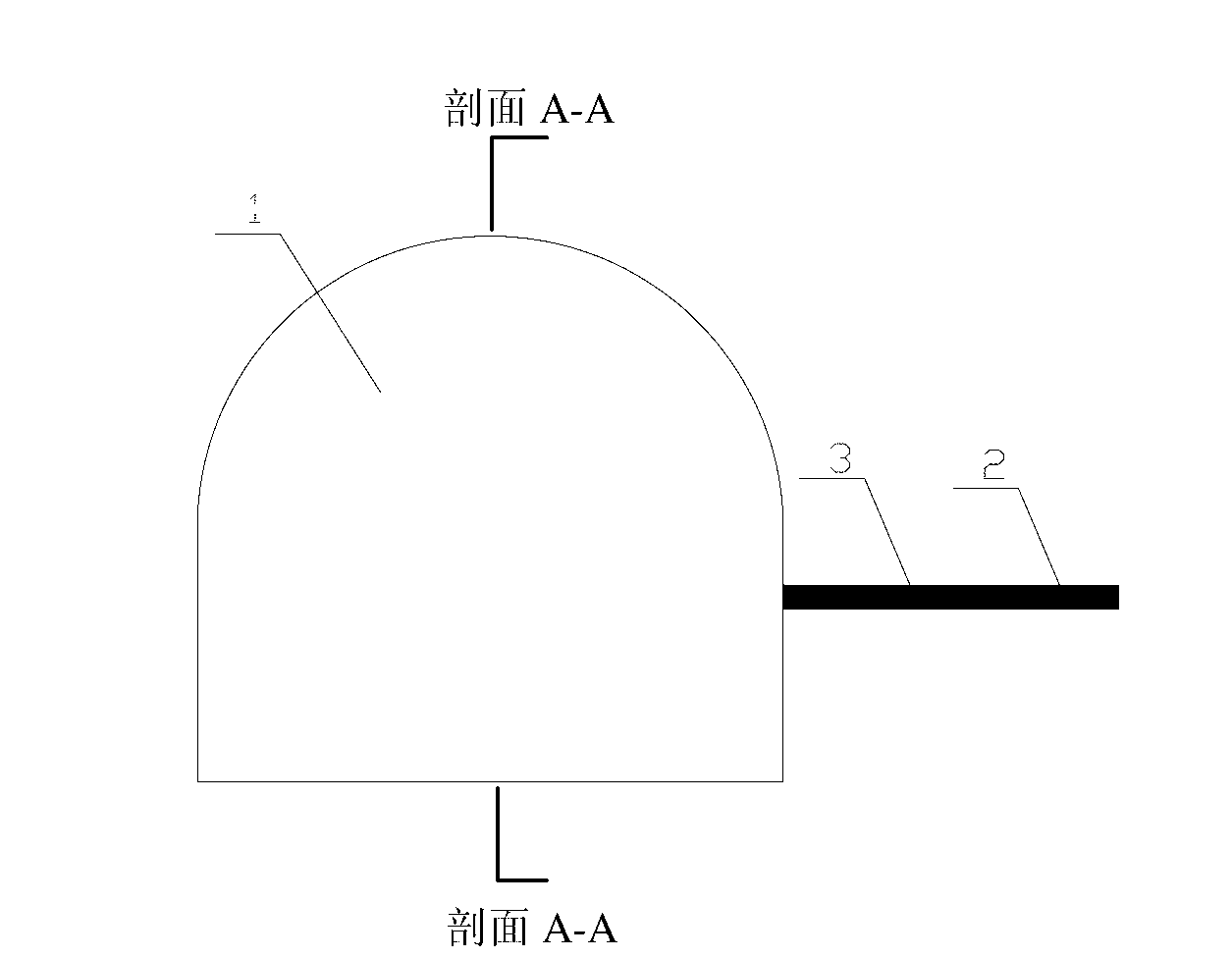

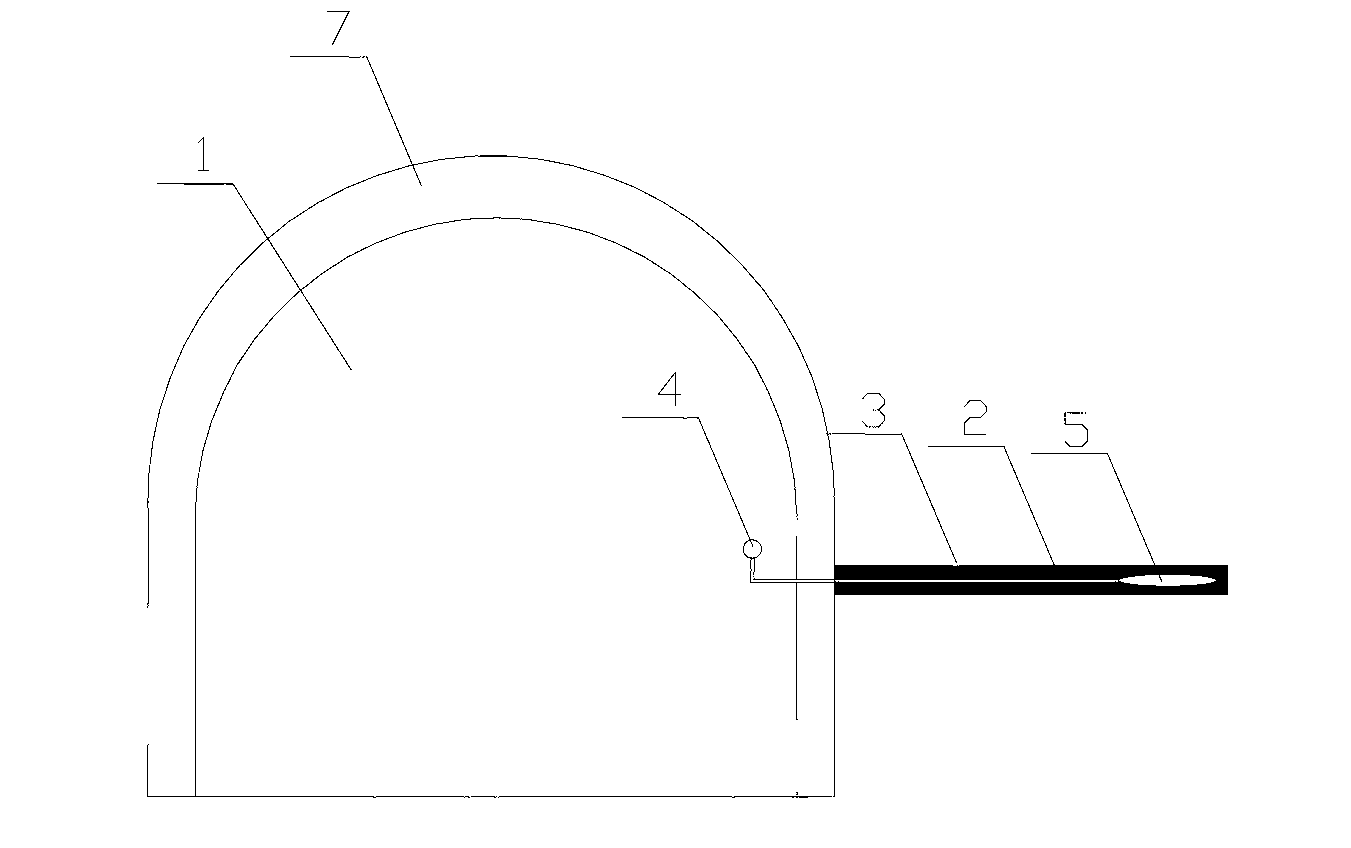

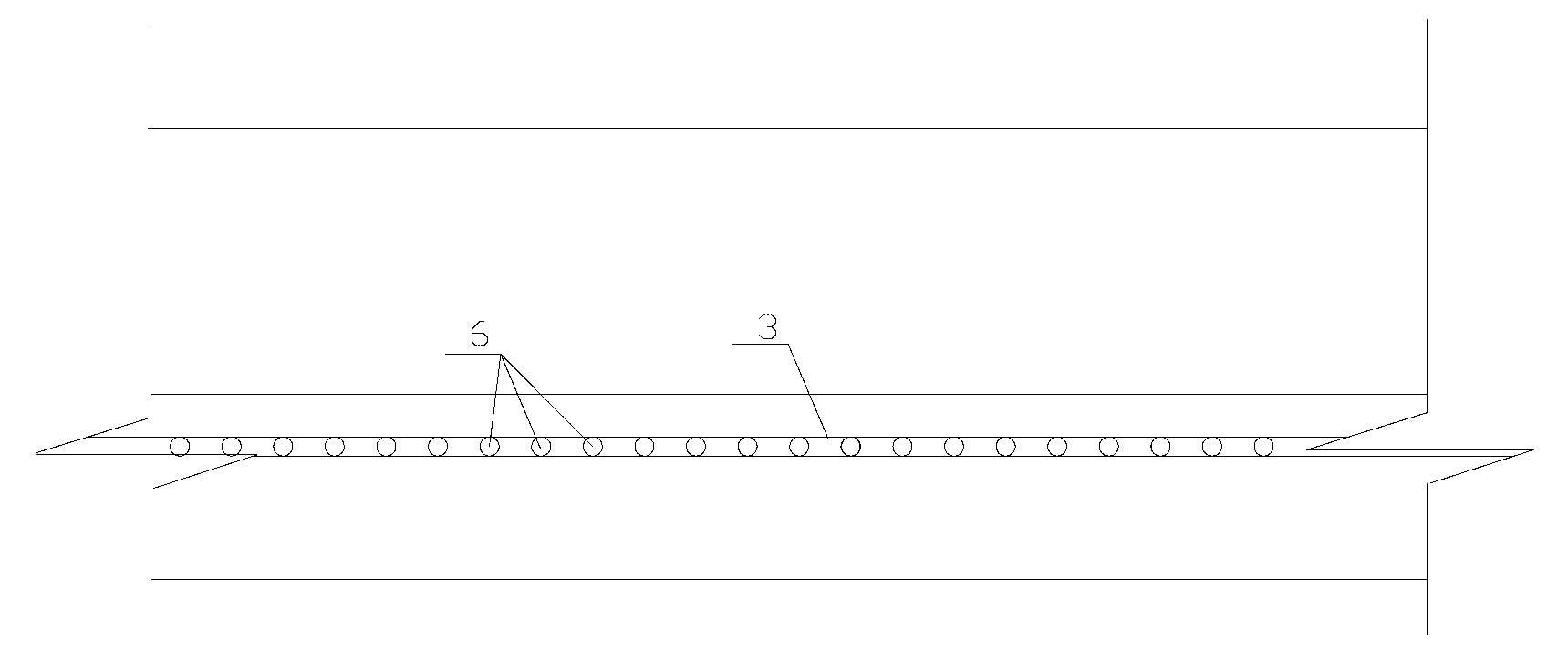

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Surrounding rock decompression mechanism: Use artificial measures to change the stress state of the surrounding rock of the roadway, so that the shallow surrounding rock of the roadway is in the stress reduction zone, so that the shallow surrounding rock of the roadway is separated from the deep rock mass, and the original high-stress state The rock formation is unloaded and the stress is transferred to the deep part of the surrounding rock. Thereby slowing down and reducing the stress level of the surrounding rock in the shallow part of the roadway.

[0022] Surrounding rock pressure relief methods: According to different pressure relief methods, it can be divided into blasting pressure relief, drilling pressure relief and cutting groove pressure relief; according to different pressure relief positions, it can be divided into bottom plate pressure relief, side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com