Manual hole digging non-uniform pile support construction technology

A technology of variable cross-section piles and manual digging, which is applied in the direction of excavation, sheet pile walls, protective devices, etc., can solve the problems of small construction space and difficult construction, and achieve cost saving, convenient construction, and strong bending and shearing resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the description.

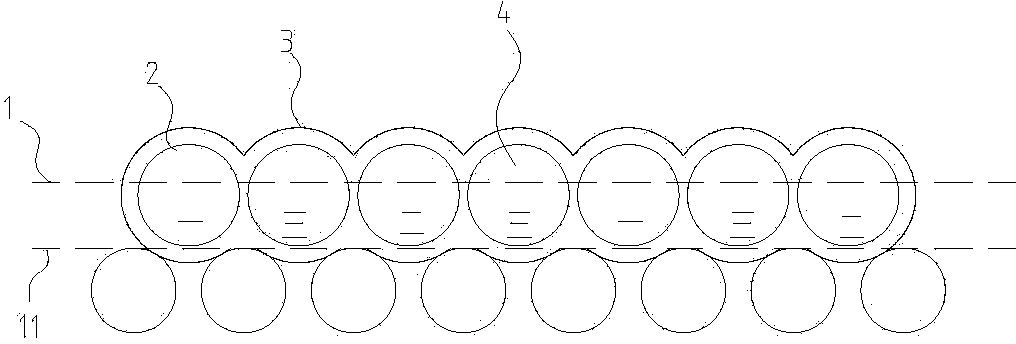

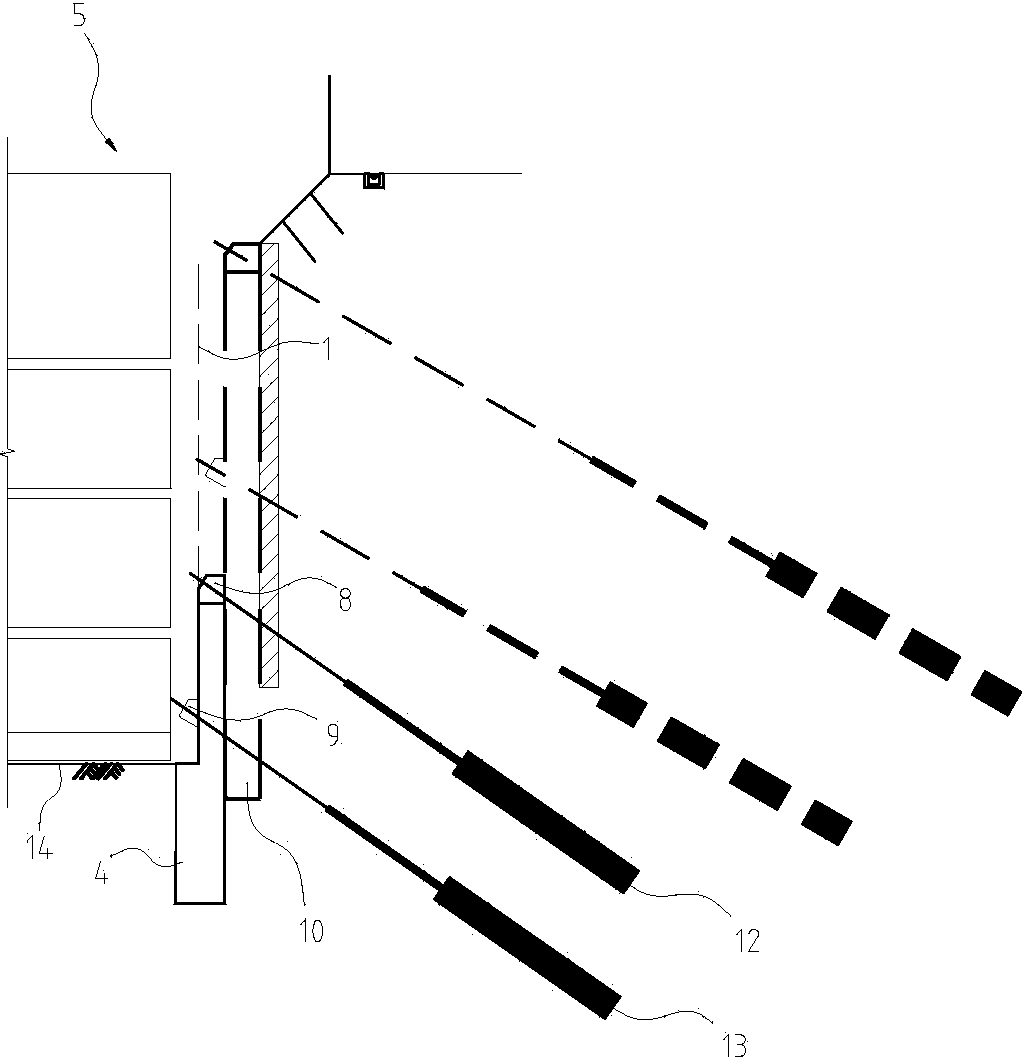

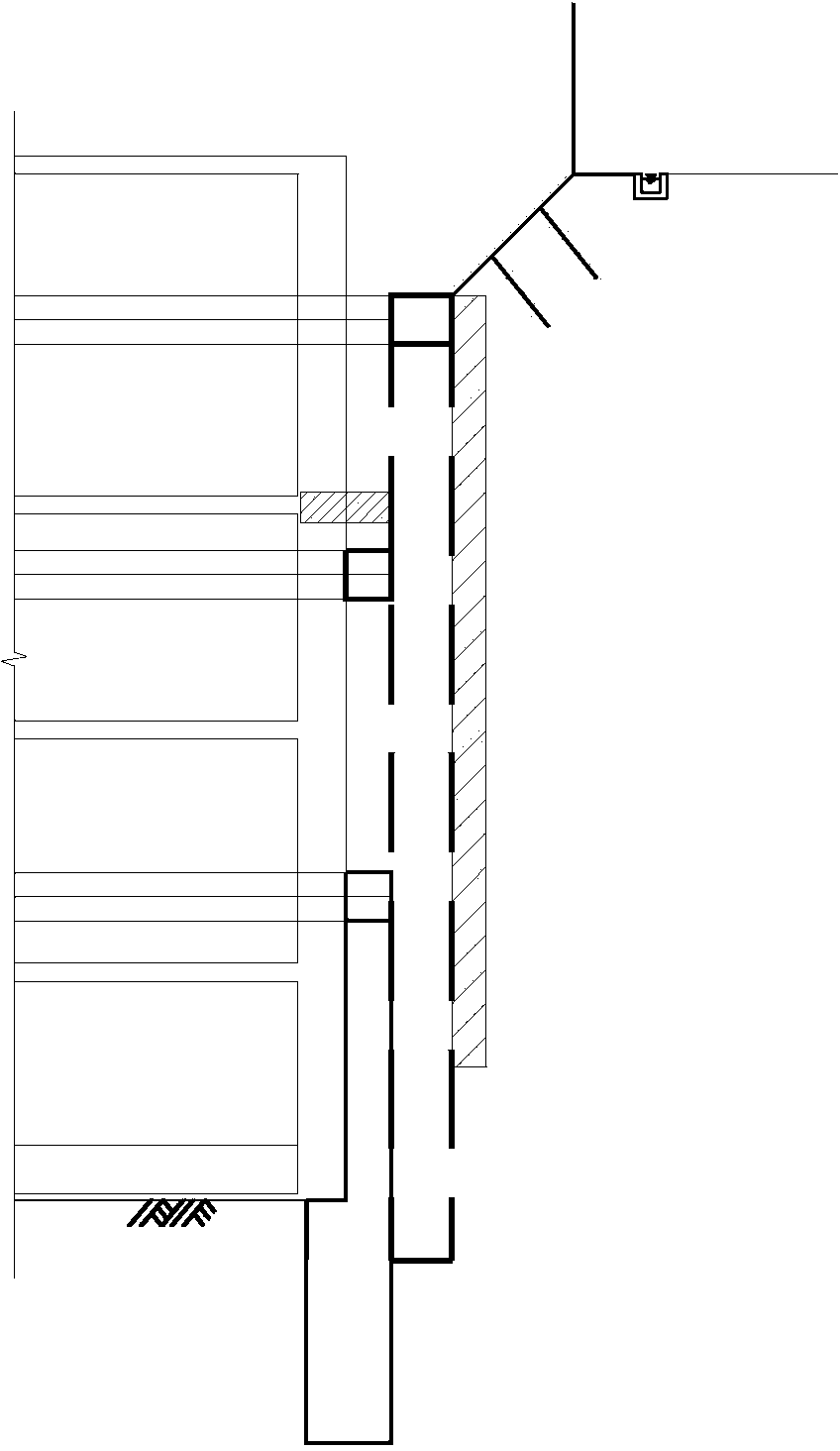

[0033] Such as Figures 1 to 5 As shown, the manual excavation variable section pile support system is composed of newly added manual excavation variable section support piles, anchor cables and / or supports, crown beams, and waist beams. It is applied to strengthen the original support structure when the bearing capacity of the original support structure is insufficient.

[0034] Before construction, first determine the size of the available space between the outer edge 11 of the original support structure and the outer edge 1 of the basement, and calculate and determine the width, reinforcement, and required horizontal support or anchor cables of the artificially dug variable-section piles above the pit bottom The spacing and specifications, the embedding depth of the support piles below the pit bottom, the reinforcement and the plane layout of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com