Additive manufacturing deformation control method for thin-wall partition plate type parts

A technology of additive manufacturing and deformation control, applied in the direction of additive manufacturing, additive processing, etc., can solve problems such as deformation of thin-walled isolation parts, and achieve the effect of improving surface quality, reducing deformation, and facilitating removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

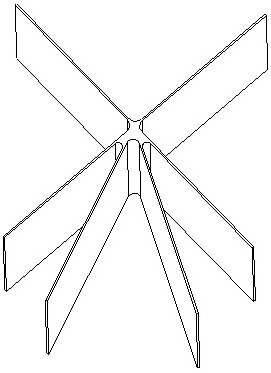

[0040] The three-dimensional number of components of the thin-walled partition component according to the present embodiment is as figure 1 As shown, the material is an aluminum alloy, and the forming method is manufactured by SLM additive. After analysis, the part size is 220 × 200 × 80mm, the thickness of the thin wall separator is 1 mm, the thin-walled part length is about 100 mm, belongs to the V-shaped part, the thin-walled structure is easy to deform, the knife, causing parts to be difficult to form .

[0041] The modification control method for manufacturing a thin-walled partition component of the present application, the steps are as follows:

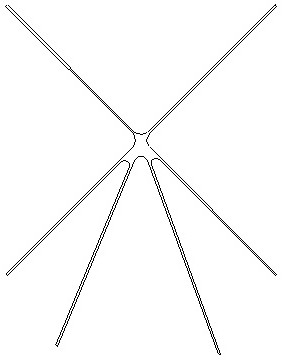

[0042] S1. Determine the placement of the part, determine the part growth direction to be parallel to each of the thin-walled partitions. The two-dimensional contour of the partial sintered part figure 2 As shown, there is no constraint in the thin plate position, which is easily deformed during the molding process, and after the...

Embodiment 2

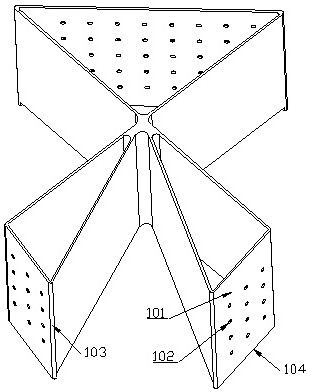

[0047] The three-dimensional number of components of the thin-walled partition component according to the present embodiment is as Figure 5 As shown, the material is a titanium alloy, and the forming method is manufactured by SLM additive. After analysis, the part size is 300 × 300 × 50mm, the thickness of the thin wall blade is 2mm, the length of the thin wall blade is about 130mm, belongs to the V-shaped part, the stress in the titanium alloy formation process, the thin-walled constitutive process is easy to deform, the knife It is difficult to form a part.

[0048] The modification control method for manufacturing a thin-walled partition component of the present application, the steps are as follows:

[0049] S1. Determine the placement of the part, determine the part growth direction to be parallel to each of the thin-walled partitions. The two-dimensional contour of the partial sintered part Figure 6 As shown, there is no constraint in the thin plate position, and the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com