Connector production method and connector structure

A production method and connector technology, which is applied in the parts, connections, and assembly/disassembly of contact pieces of connection devices, can solve problems such as difficult demoulding, uneven connection methods, and irregular terminal arrangements, etc., to achieve Simplified workflow, compact and firm assembly, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

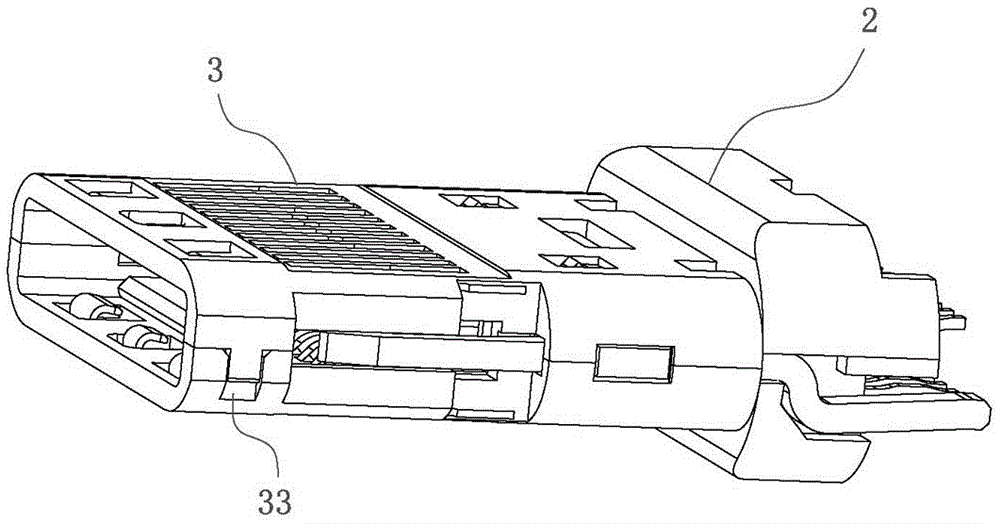

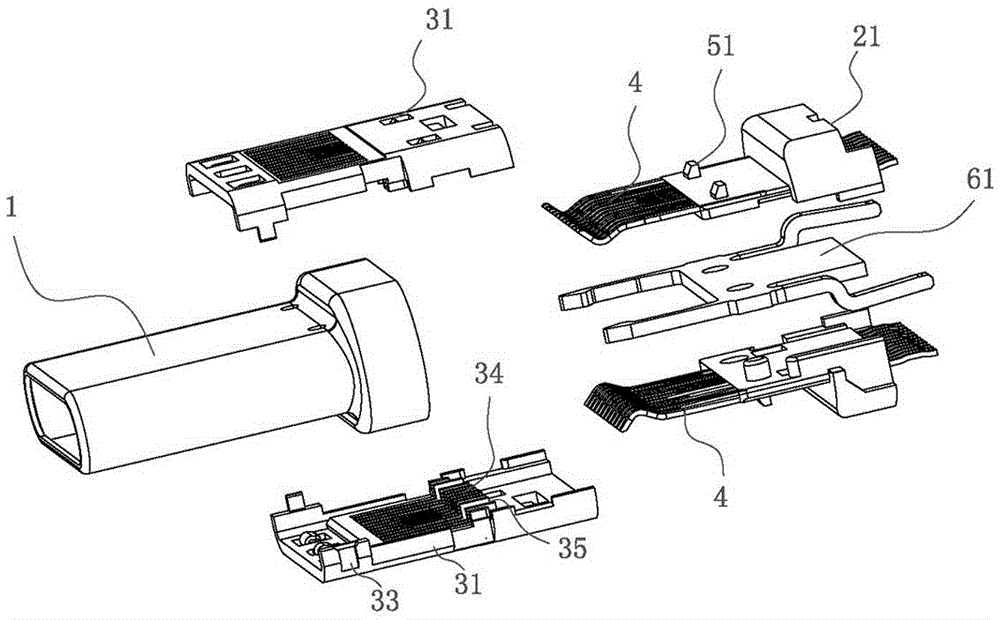

[0034] A production method of a connector provided by the present invention has a structure such as Figure 1 to Figure 6 shown, including the following steps:

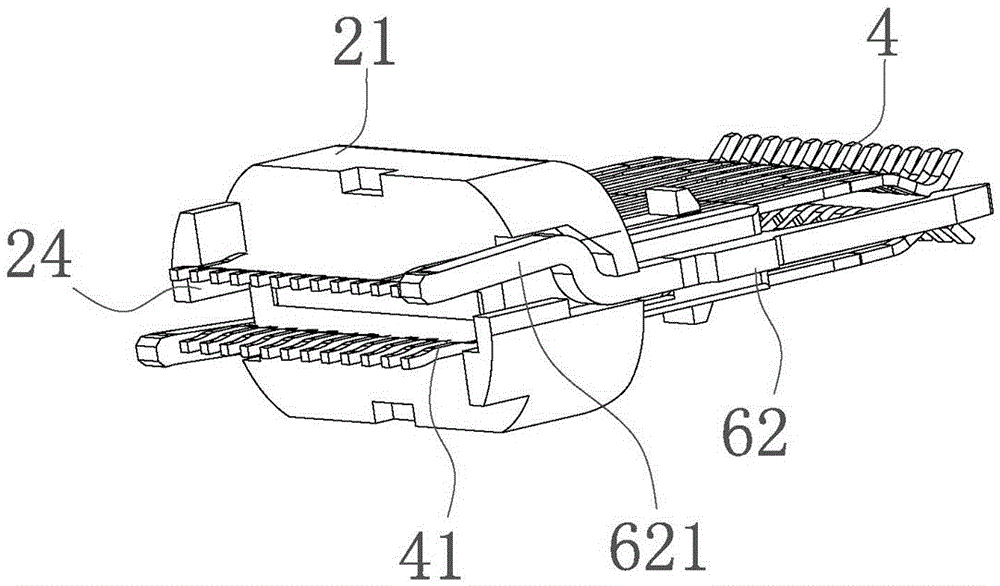

[0035] Step A: Injection molding the front rubber core unit 31 and the rear rubber core unit 21 respectively, wherein several terminals 4 are arranged in a row and placed in the injection mold, and the rear rubber core unit 21 is injection molded on the neatly arranged terminals 4 ;

[0036] Step B: fixedly connect the front rubber core unit 31 to the rear rubber core unit 21, and one front rubber core unit 31 and one rear rubber core unit 21 form a connector unit;

[0037] Step C: Any two connector units are buckled together to form a connector body, wherein the front rubber core unit 31 is buckled to form the front rubber core module 3, and the rear rubber core unit 21 is buckled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com