Gypsum board stacking machine and stacking method

A technology of gypsum board and laminating machine, which is applied in the direction of conveyors, conveyor objects, object stacking, etc., which can solve the problems of high working noise and broken gypsum boards, and achieve high work efficiency and smooth lamination process , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

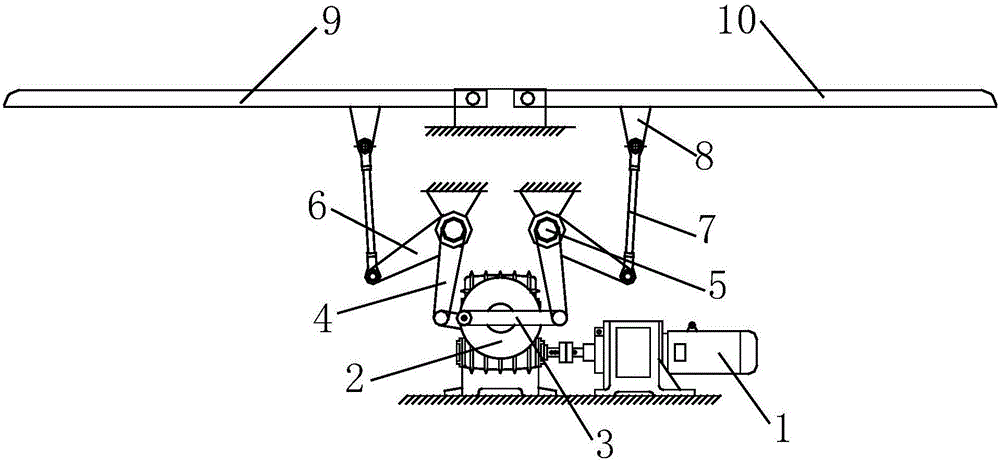

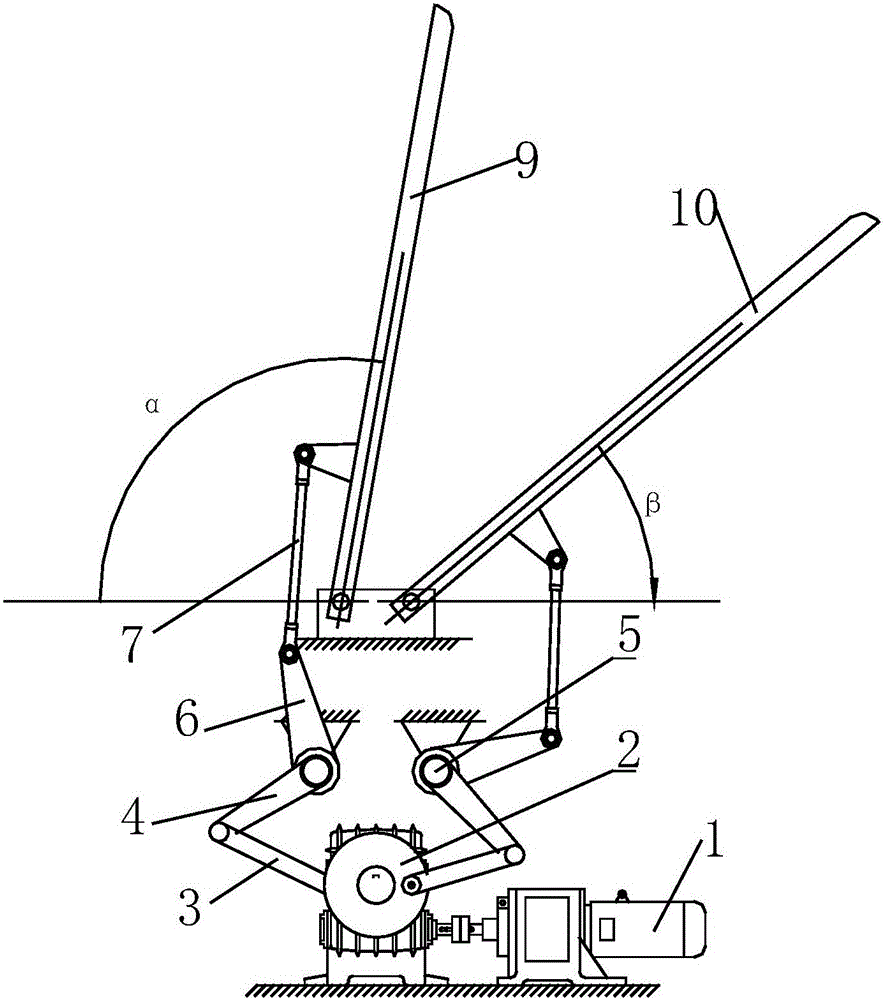

[0022] The gypsum board combining machine includes a deceleration four-bar mechanism and a motor 1. The deceleration four-bar mechanism includes two sets of rotating mechanisms, and the two sets of rotating mechanisms include a connecting rod 3, a rocker 4, a rotating shaft 5 and a fork that are sequentially connected in rotation. Both connecting rods 3 are rotationally connected with the same crank 2, and two sets of rotating mechanisms are arranged symmetrically on both sides of the crank 2; the forks are divided into the flipper fork 9 that receives the plasterboard in the horizontal position and flips it over, and the flipper fork that receives the flip After the gypsum board and turn it to the connecting plate fork 10 of the horizontal position, the turning plate fork 9 and the connecting plate fork 10 are symmetrically arranged, the motor 1 drives the crank 2 to rotate and drives the described turning plate fork 9 and the described connecting plate respectively The fork 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com