Light source group and side-view backlight module

A technology of backlight module and light source group, applied in the direction of light source, point light source, optics, etc., can solve the problems of wasting light-emitting components, time-consuming disassembly and assembly, and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

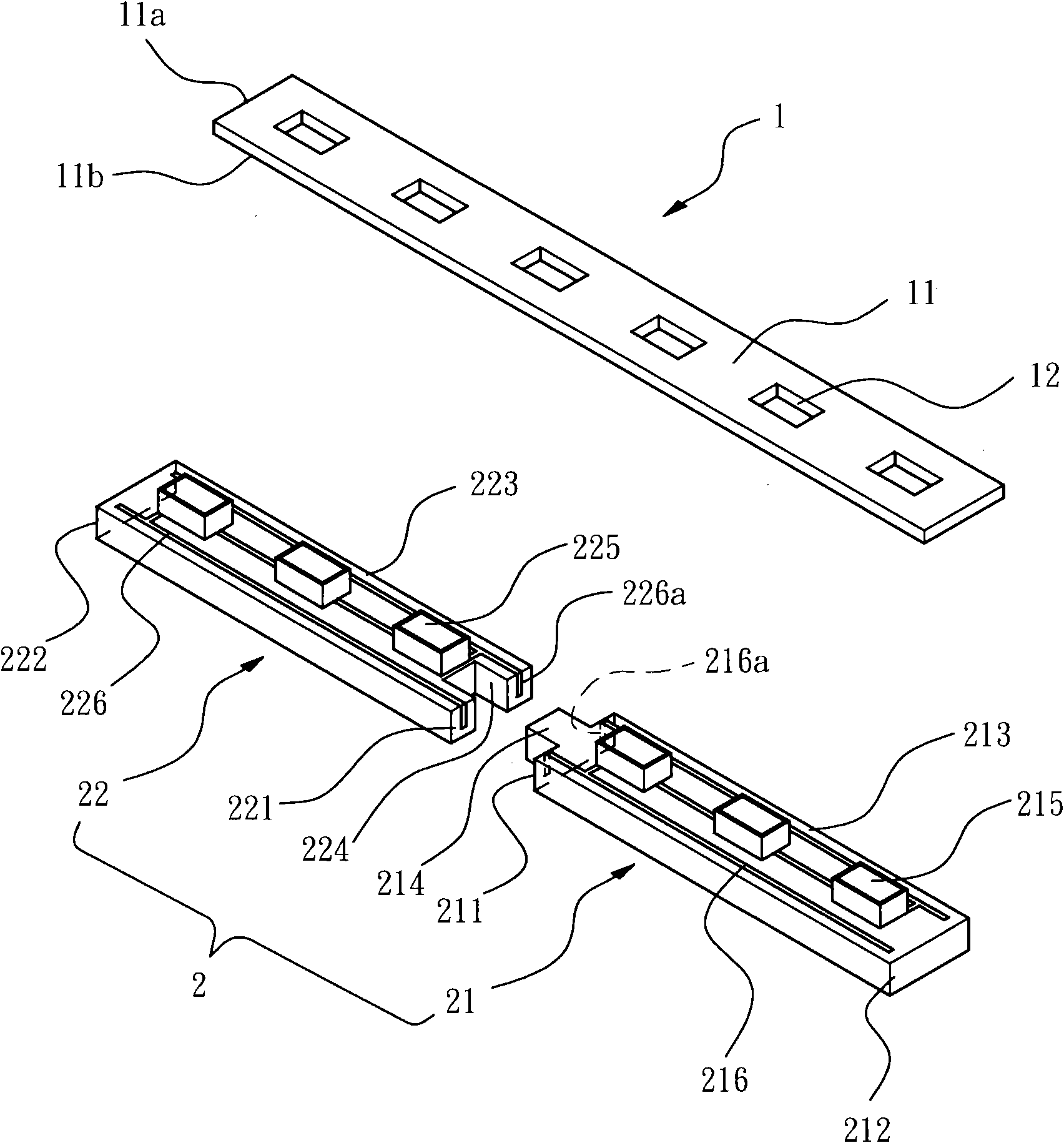

[0034] Please refer to image 3 , which discloses a partial top view of the light source group of the second embodiment of the present invention. The structure and operation of the light source group of the second embodiment of the present invention are similar to the aforementioned first embodiment of the present invention, that is, the light source group of the second embodiment It is also composed of several unit bodies, and the unit bodies can be detachably connected to each other along the longitudinal direction to form a strip-shaped light source group, but the difference between the two lies in: the second embodiment The connection part used to connect several unit cells in the light source group has a different geometry from that of the first embodiment. In the following description, the same parts or parts in the structure of the second embodiment as those of the first embodiment are marked with the same reference numerals, and the description thereof will be omitted....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com