Milling cutter device with function of adjusting height of blade

A kind of blade and high technology, applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of reducing the service life of milling cutters, reducing the smoothness of the processing surface, and blade wear, etc., to prevent the blade from breaking, increasing the clamping force, Enhance the effect of power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

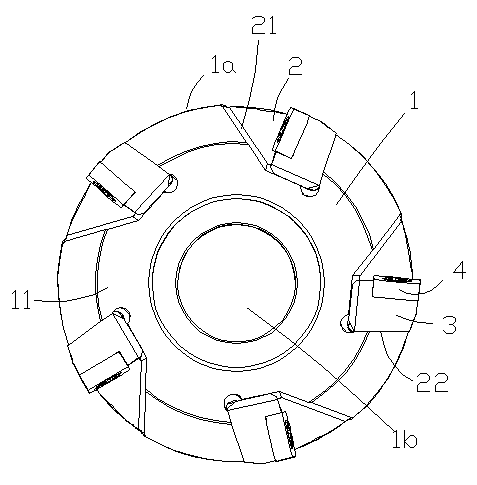

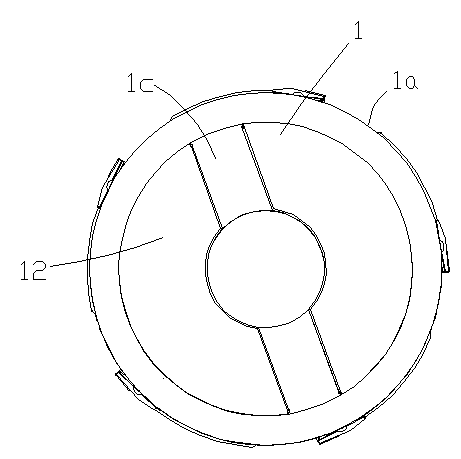

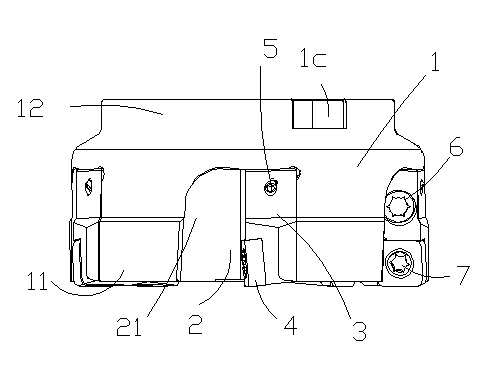

[0025] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

[0026] one of them Figure 1 to Figure 3 The reference signs in are: cutterhead body 1, circumferential surface 1a, drive shaft hole 1b, keyway 1c, front disk body 11, rear disk body 12, tool groove 2, chip removal slope 21, tool holder mounting surface 22, Tool holder 3, blade 4, contour adjusting screw 5, tool holder clamping screw 6, blade pressing screw 7.

[0027] A milling cutter device with the function of adjusting the blade height of the present invention includes a cutter head body 1, and a drive shaft hole 1b is provided at the center of the cutter head body 1; There is at least one tool slot 2 and the tool slot 2 extends to the front side of the cutter body 1, a tool holder 3 is installed in the tool slot 2, and the tool slot 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com