Slurry dehydration combined system

A combined system and mud technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of great deviation of dry mud mud content and troublesome sludge reuse, and achieve stable dry mud mud content and treatment Stable, combined effect with small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

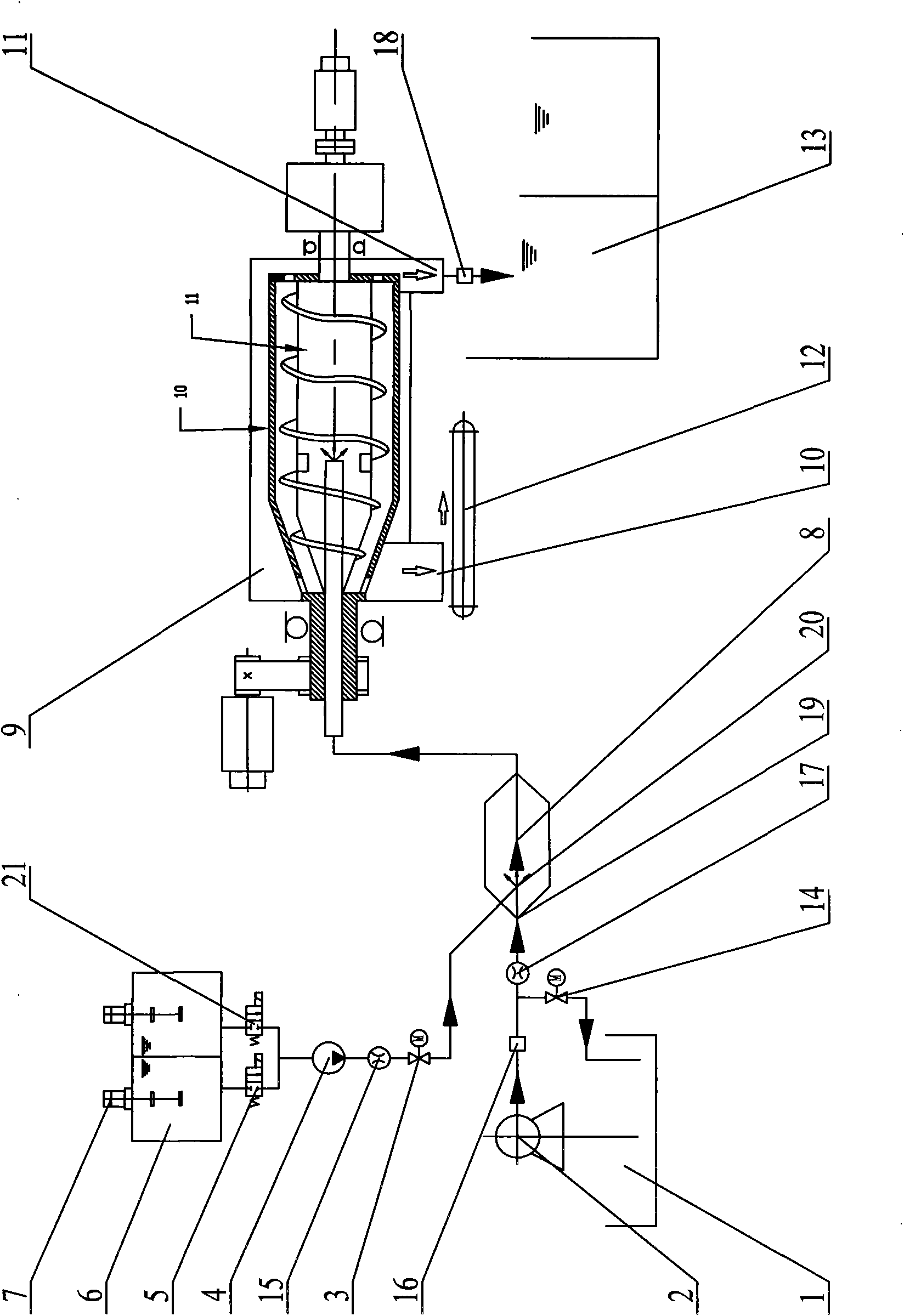

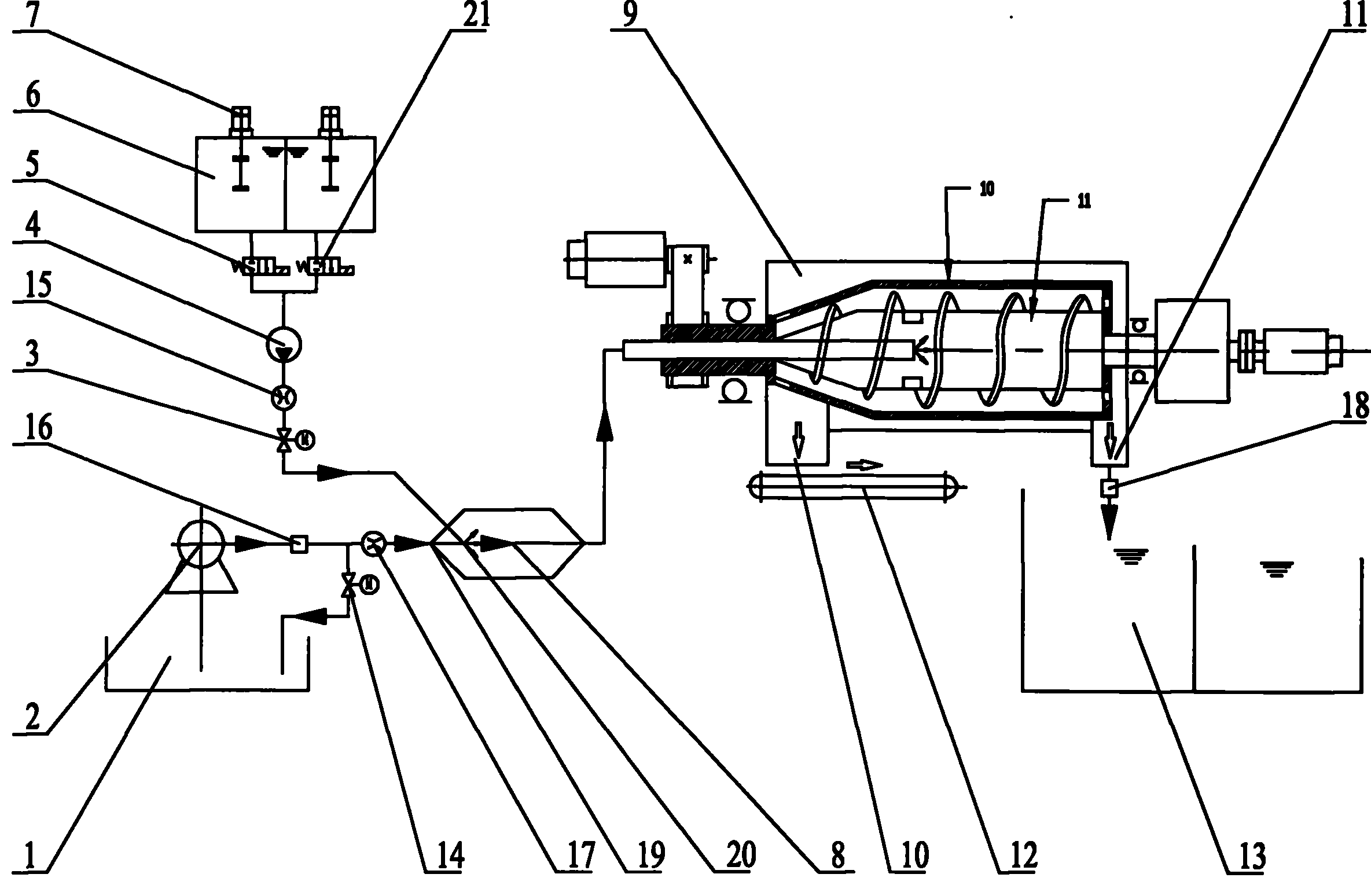

[0015] Such as figure 1 As shown: the mud dehydration combination device includes mud turnover box 1, mud pump 2, first electric valve 3, chemical delivery pump 4, solenoid valve 5, chemical dilution box 6, mixer 7, mixer 8, centrifuge 9, dry mud Outlet 10, liquid outlet 11, dry mud conveyor 12, secondary settling tank 13, second electric valve 14, first flow meter 15, mud concentration detector 16, second flow meter 17, turbidity meter 18, mud inlet 19. Drug inlet 20, second solenoid valve 21, etc.

[0016] The present invention comprises a mud turnover box 1, a medicine dilution box 6, a flow mixer 8 and a centrifuge 9, one end of the flow mixer 8 is provided with a mud inlet 19 and a medicine inlet 20, and the other end of the flow mixer 8 is provided with an output port; The mud turnover box 1 is provided with a mud pump 2, and the mud pump 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com