Tester and testing method for cement-base material cracking and contracting characleristics

A cement-based material, shrinkage performance technology, applied in the direction of measuring devices, analysis materials, material inspection products, etc., can solve the problems that shrinkage performance has not been seen, and there is a gap in cracking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

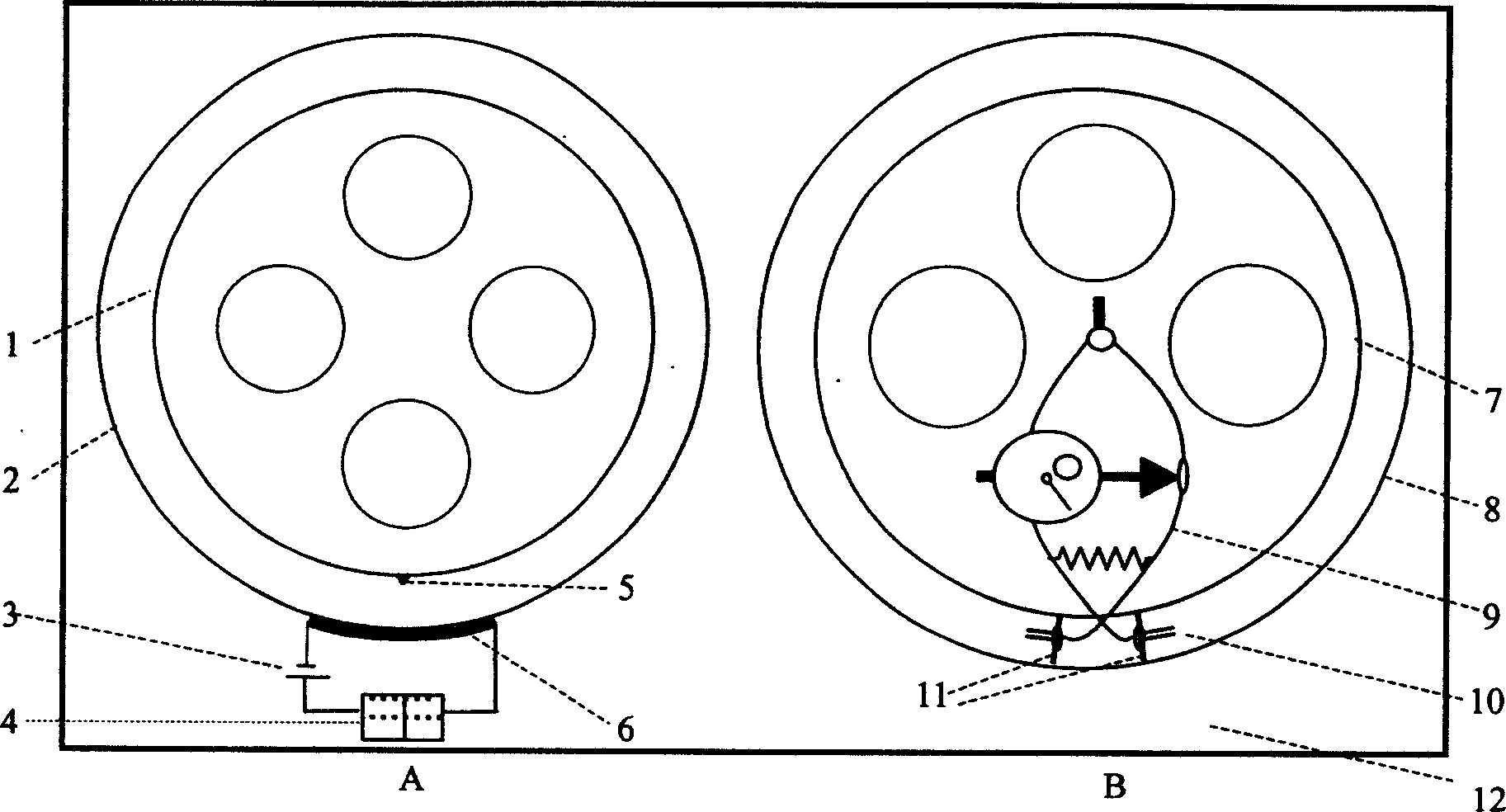

[0018] 1. Fabrication of testing device for cracking and shrinkage performance of cement-based materials

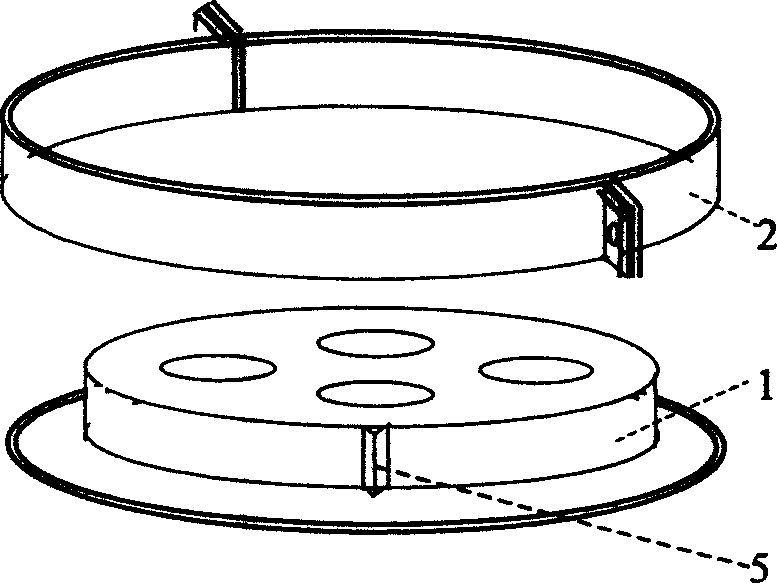

[0019] The test device for cracking of cement-based materials is attached figure 2 , the diameter of mold A’s restricted inner ring 1 is designed to be 26.65cm, the diameter of detachable outer ring 2 is designed to be 34.65cm, the distance between the inner and outer rings is 4cm, and a side bottom edge is set outside the inner ring An isosceles triangular protruding wedge 5 with a length and a height of 0.3 cm;

[0020] The test circuit is composed of enamelled thin copper wire, power supply, timer and connecting wires. The enamelled copper wire can be thin copper wire in ordinary multi-strand copper core wire;

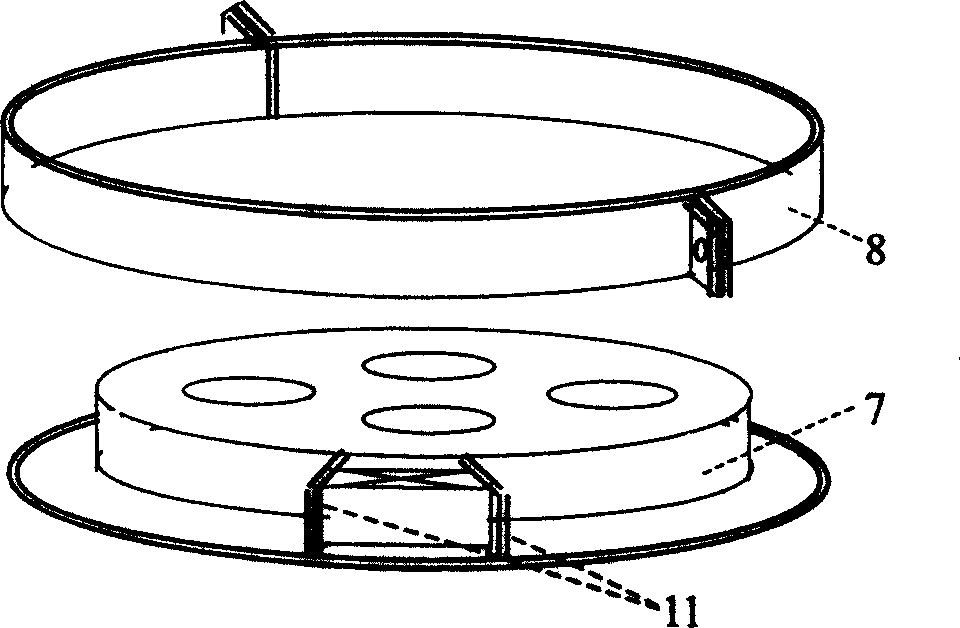

[0021] The test device for the shrinkage performance of cement-based materials is attached image 3 , the diameter of the limited inner ring 7 of mold B is designed to be 27.65cm, the diameter of the detachable outer ring 8 is designed to be 35.65cm, the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com