Oxide target material and preparation method thereof

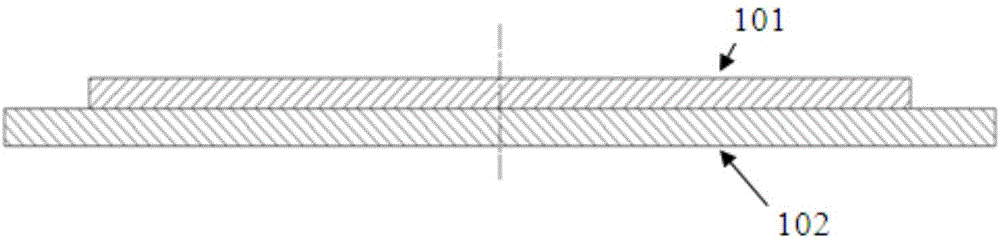

A technology of oxides and targets, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of uneven sintering stress and cracking of targets, and reduce the risk of cracking, reduce cracks and even Cracking, the effect of reducing variance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Al 2 o 3 Target preparation

[0026] Using 99.99% high-purity Al 2 o 3 The powder is uniformly mixed, then evenly spread in a hot-pressing mold with a diameter of 165mm, and then evenly pressed, and finally pressurized at 1400°C for densification and sintering to obtain Al 2 o 3 Target blank.

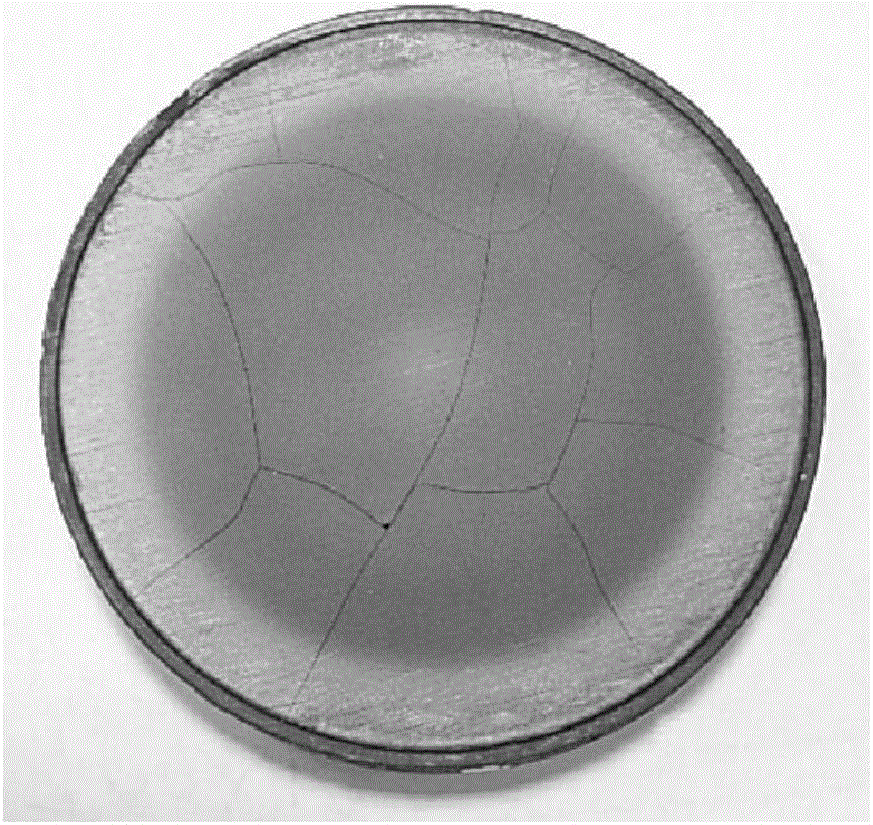

[0027] The detected Al 2 o 3 The relative density of the target blank is 99.5%; then the whole block of Al is scanned by ultrasonic C 2 o 3 The target blank is scanned, and the internal information of the target blank is detected according to the ultrasonic wave, and the density uniformity fluctuation of each part of the target blank is evaluated, and the fluctuation is not more than 5%.

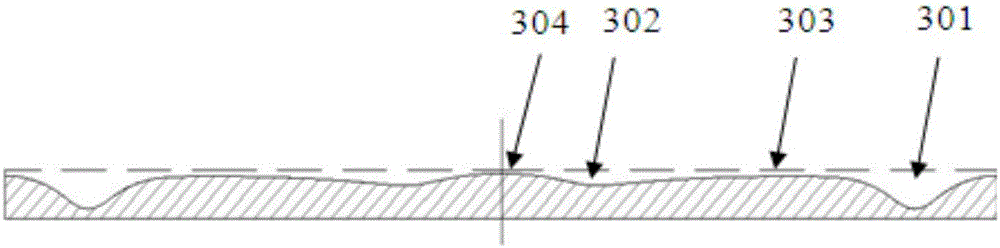

[0028] Al will be obtained 2 o 3 The target blank is cut and processed into a size of Al 2 o 3 Target blank; then in Al 2 o 3 The outer edge of the sputtering surface of the target blank is processed with a chamfer 403, the angle is 45°, and the height H is 2.5mm; 2...

Embodiment 2

[0031] Embodiment 2: Preparation of MgO target material

[0032] Use 99.99% high-purity MgO powder for uniform powder mixing, then evenly spread it in a hot-pressing mold with a diameter of 215mm, and then apply pressure evenly, and finally pressurize at 1400°C for densification and sintering to obtain the MgO target blank.

[0033] The relative density of the MgO target blank obtained through testing is 99.5%; then the entire MgO target blank is scanned by ultrasonic C-scanning, and the internal information of the target blank is detected according to the ultrasonic wave, and the density uniformity fluctuation of each part of the target blank is evaluated. Its volatility is not greater than 5%.

[0034] The obtained MgO target blank is cut and processed into a size of MgO target blank; then process a fillet 504 on the outer edge of the sputtering surface of the MgO target blank, the radius R of the fillet is 2.5mm; the thickness T1 of the first main sputtering region 501 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com