Metal structure fatigue crack propagation life prediction method based on material R curve

A technology of fatigue crack growth and metal structure, applied in the direction of analyzing materials, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0065] Step 1 Determination of material P-v curve:

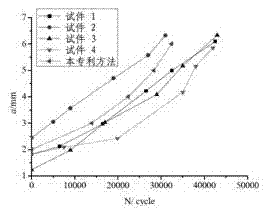

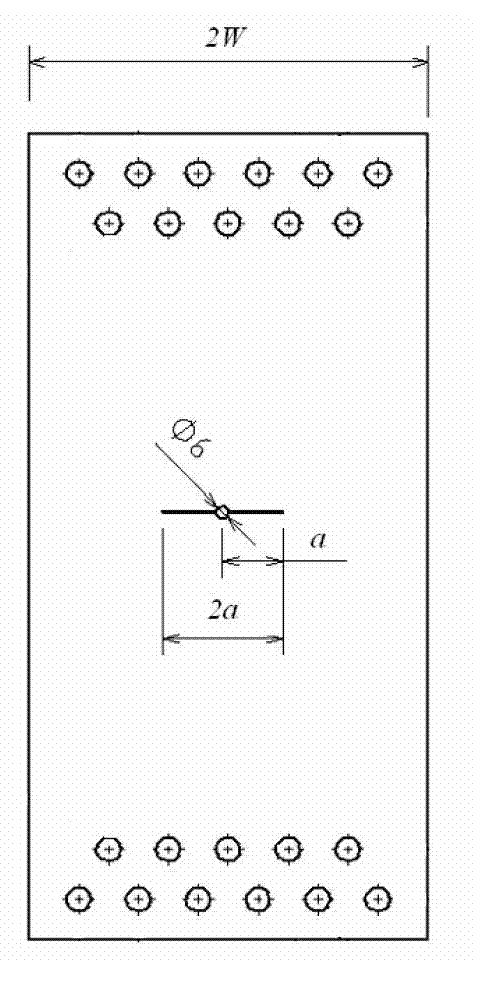

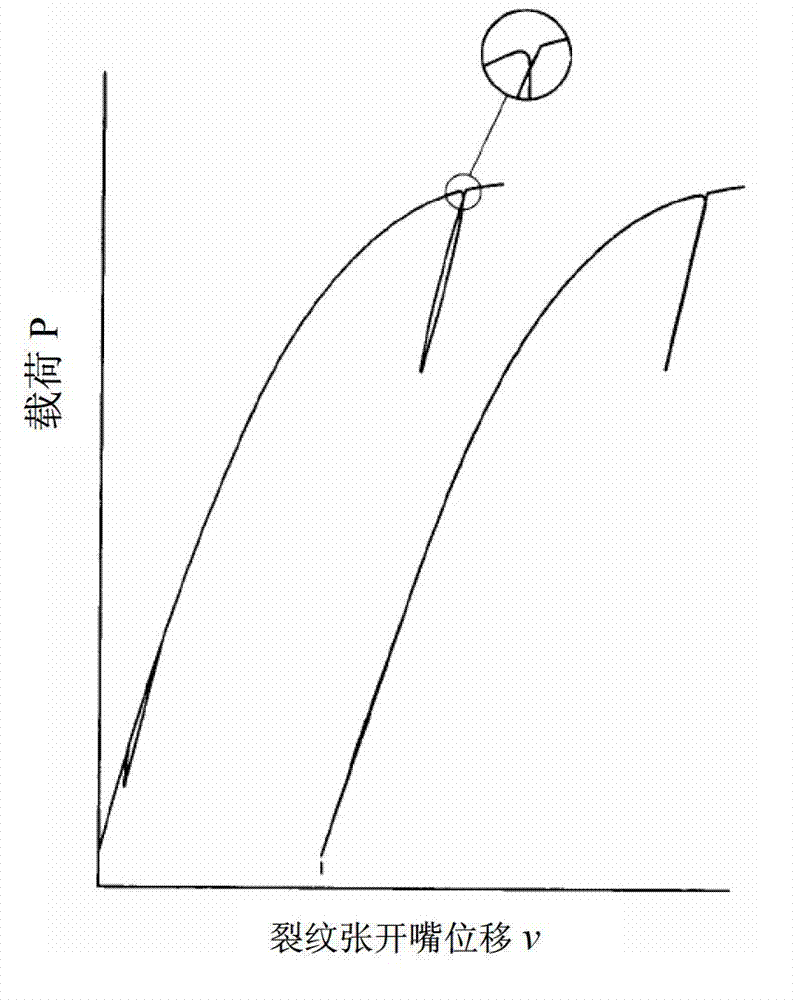

[0066] The material of the test piece is 7050-T7410 aluminum alloy plate, and the size design is as follows: Image 6 As shown, the sample thickness is 6.7mm. The test determination of the material P-v curve meets the requirements of the navigation mark HB5261-83 "Metal Sheet KR Curve Test Method". The P-v curve obtained from the test is shown in Figure 7 .

[0067] Step 2 Fitting of material R curve expression:

[0068] Step (a), using the flexibility method to calculate the crack half-length a:

[0069] According to the "ASTM E561-08 Standard Test Method for K-R Curve Determination" standard, the formula for calculating the flexibility of CCT samples is:

[0070] 2 a W = 1.2235 x - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com