High-cycle fatigue and low-intensity impact coupled damage calculation method based on nominal stress method

A technology of high cycle fatigue and nominal stress, which is applied in the field of fatigue damage analysis and reliability evaluation, and can solve problems such as product impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

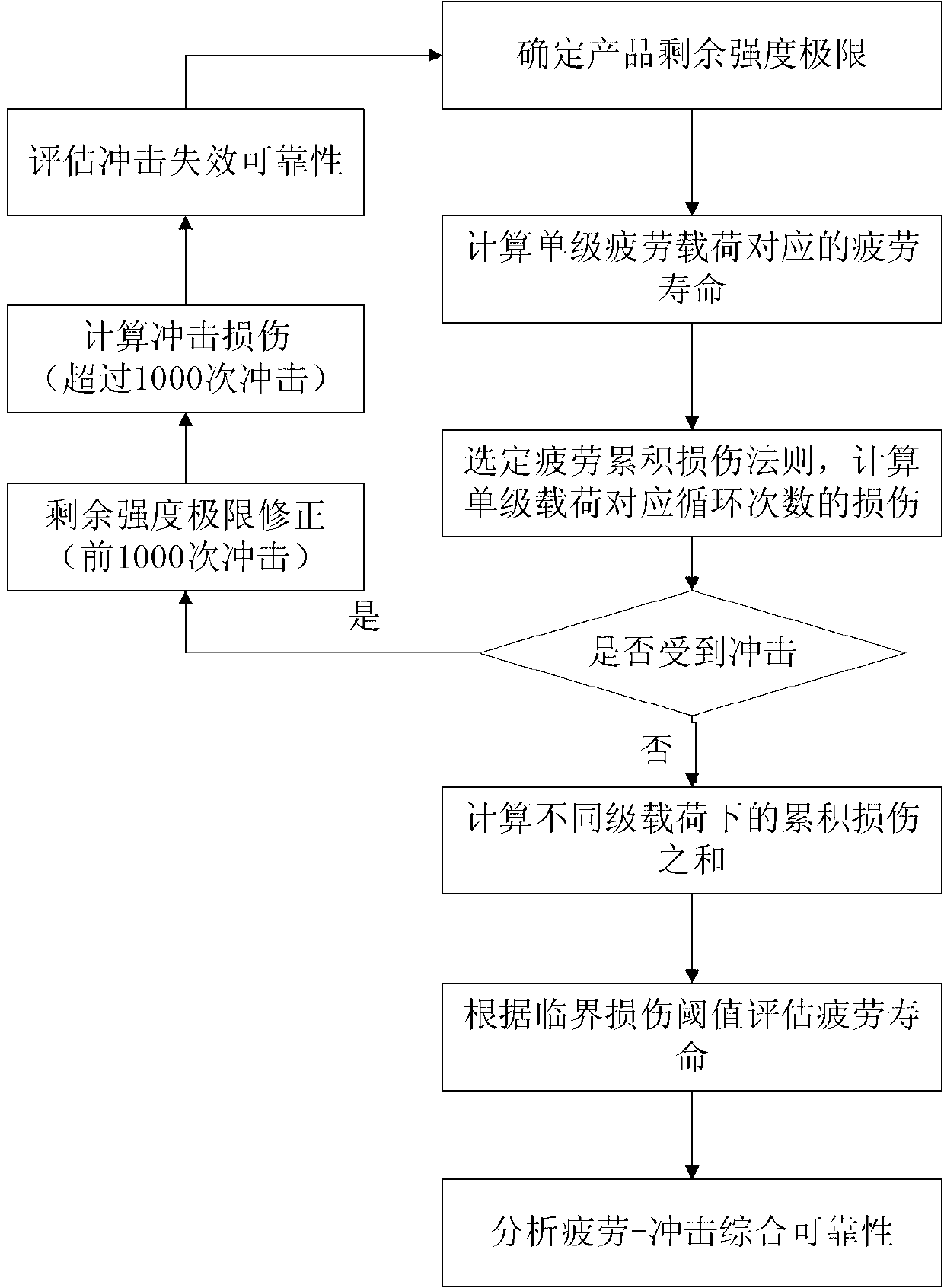

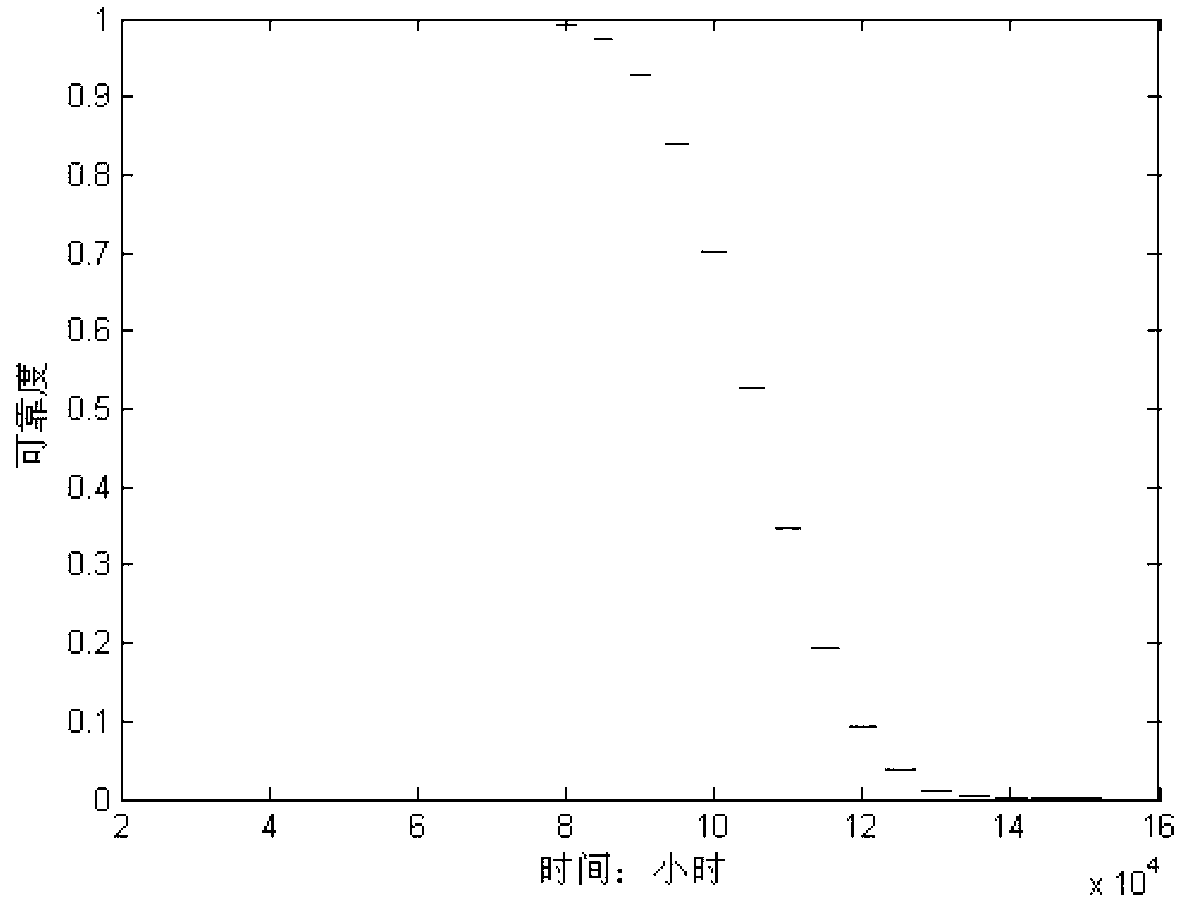

[0162] The following examples are as follows figure 1 The process shown is carried out, and the case selects an actuator cylinder as the fatigue-shock analysis object, which mainly includes analyzing the characteristics of the impact load, determining its type, analyzing and selecting a suitable fatigue cumulative damage model, and calculating the fatigue cumulative damage after impact , Estimation of fatigue damage probability, establishment of product strength affected by fatigue damage model, establishment of reliability evaluation model. Specific steps are as follows:

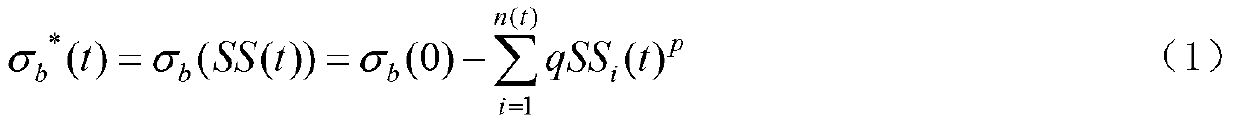

[0163] Step 1: Collect product information, determine the fatigue limit of the product, use the Basquin formula to calculate the fatigue life corresponding to the single-stage load only under the action of fatigue load; analyze the fatigue cumulative damage mode, and selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com