Metal material crack type defect depth measuring device and method

A metal material, defect depth technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve the problems of low sensitivity of plane defects, complex detection system, stress concentration, etc., to achieve simple equipment and operation, The effect of simple signal processing and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

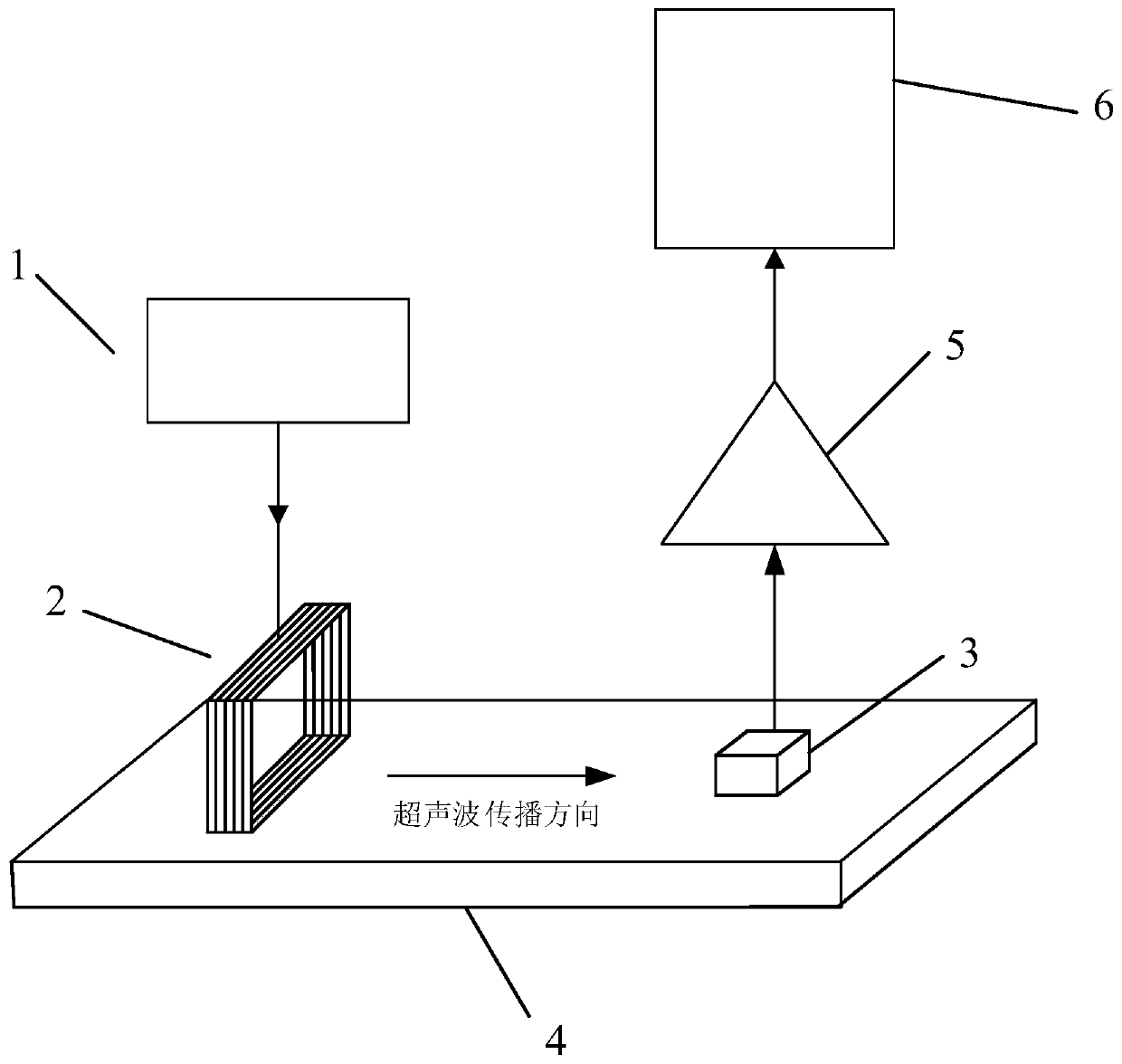

[0020] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

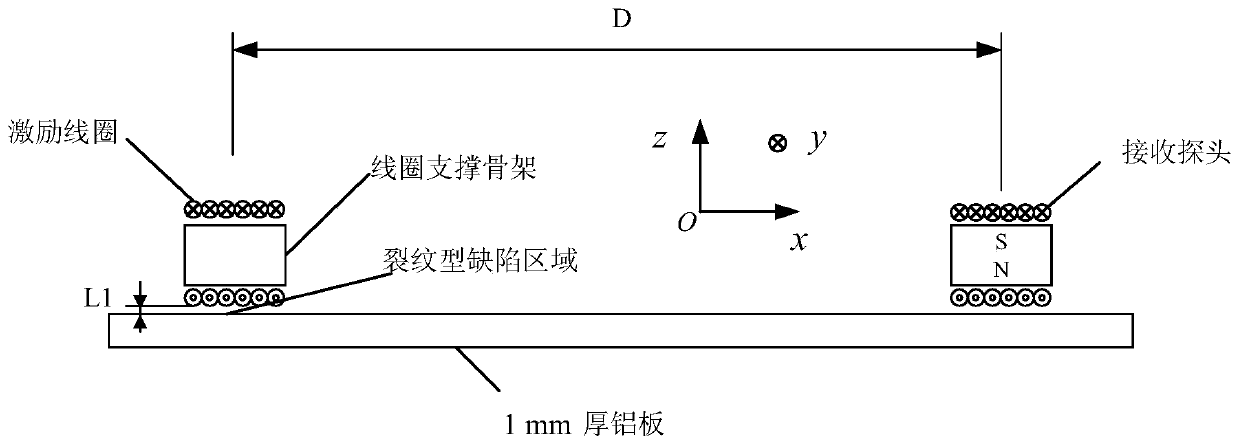

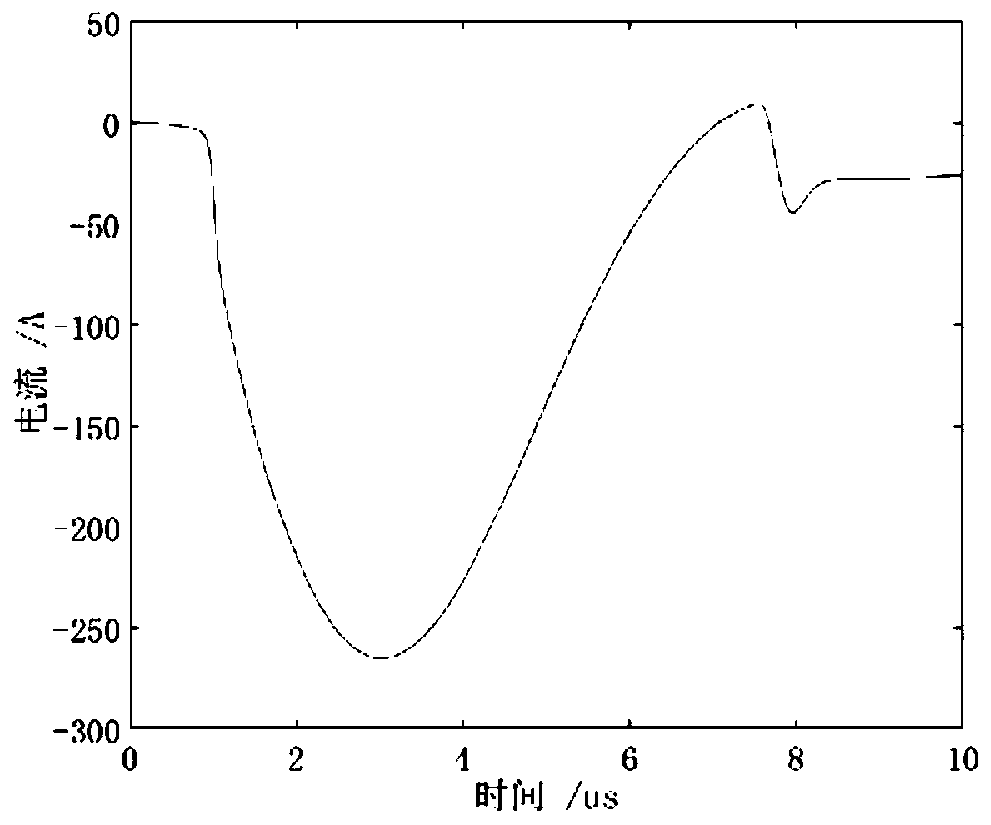

[0021] The sample to be tested is an aluminum plate with a thickness of 1 mm, so there is only a Lorentz force mechanism in the excitation process, and the receiving transducer uses an electromagnetic ultrasonic transducer based on the Lorentz force mechanism. Implementation structure such as figure 2 As shown, the excitation coil adopts 6 turns of rectangular coil with a diameter of 1mm, and the coil is made of enameled copper wire; the dimensions of the coil along the y-direction and z-direction are 30mm and 15mm, respectively, and the axial direction of the coil is parallel to the x-axis. Lifting distance L of excitation coil 1 =1mm; the pulse current passed into the excitation coil is such as image 3 As shown, the maximum current is about 270A, and the pulse duration is about 7 μs. The receiving probe adopts an electromagnetic ultrasonic transdu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com