Method for monitoring cement-based material crack by using electrochemical impedance spectroscopy in real time

A cement-based material, real-time monitoring technology, applied in the direction of material analysis, material analysis, and measuring devices through electromagnetic means, can solve the problems of long test time, large impact, complicated operation, etc., and achieve fast measurement speed and anti-interference ability Strong, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

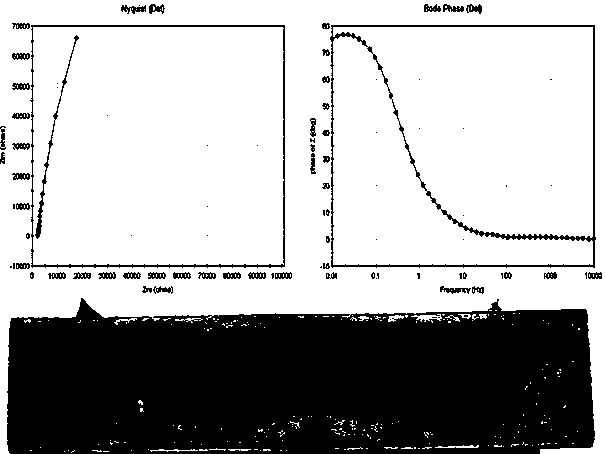

[0047] 3. Example 1: Detection of the natural expansion and cracking process of cement-based material specimen 9 (under no-load conditions)

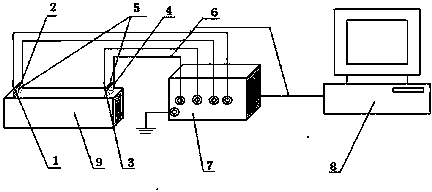

[0048] First, pre-embed electrode sheets 5 (can be self-made) at both ends of the prediction area of the cement-based material specimen 9 (the electrode sheet 5 can be a nickel electrode sheet), and then connect the electrode sheet 5 to the electrochemical workstation for data collection through the wire 6 The system 7 is connected, and then the electrochemical workstation data acquisition system 7 is connected with the computer data processing system 8; secondly, the sinusoidal AC voltage disturbance signal with a frequency of 10mHz~10kHz and an amplitude of 5mV is passed through the electrode piece 5 (can be self-made) (the electrode piece 5 can be Nickel electrode sheet) is applied to the cement-based material specimen 9, and the response signal, that is, the sinusoidal alternating current signal, is collected by the data acquisition...

Embodiment 2

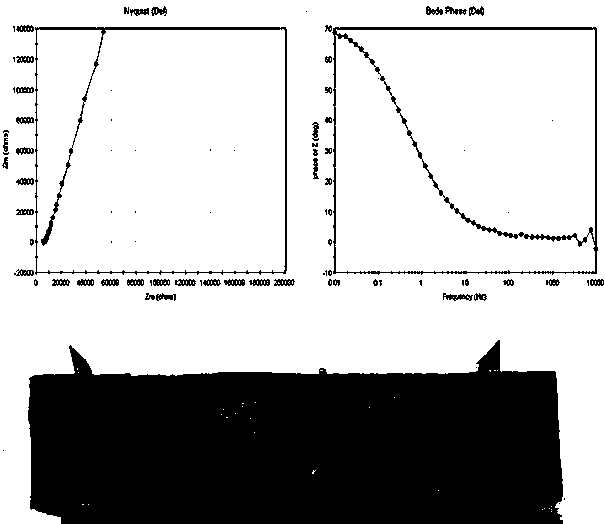

[0050] Example 2: Detection of cracks (prefabricated cracks) in the cracking process of cement-based material specimen 9 preloaded (under load conditions)

[0051] First, pre-embed electrode sheets 5 (can be self-made) at both ends of the prediction area of the cement-based material specimen 9 (the electrode sheet 5 can be a nickel electrode sheet), and then connect the electrode sheet 5 to the electrochemical workstation for data collection through the wire 6 The system 7 is connected, and then the electrochemical workstation data acquisition system 7 is connected with the computer data processing system 8; secondly, the sinusoidal alternating current disturbance signal with a frequency of 10mHz~10kHz and an amplitude of 10mA is applied to the cement-based material specimen 9 through the electrode sheet 5 , the response signal, that is, the sinusoidal alternating current signal, is collected by the data acquisition system 7 of the electrochemical workstation, and then the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com