Steel pipe pile construction system and process based on floating pile stabilizing platform

A technology for steel pipe piles and stabilizing piles, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of multiple vibration effects, low work efficiency, and poor accuracy of the pile stabilization platform, and achieves improved verticality control accuracy and reduced Effective working hours and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

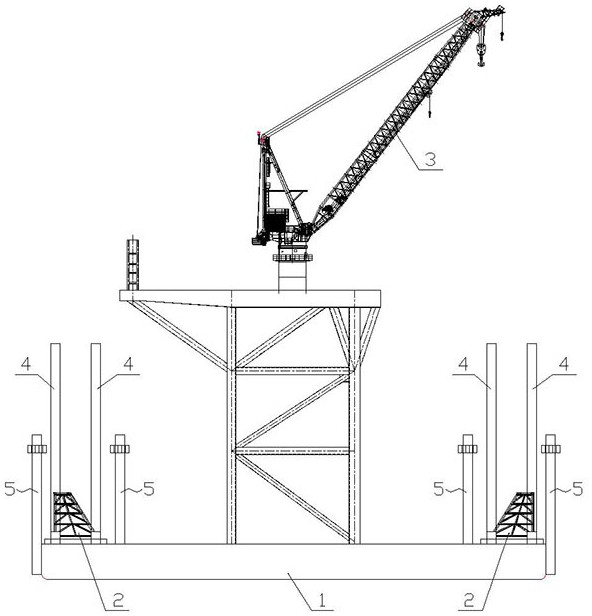

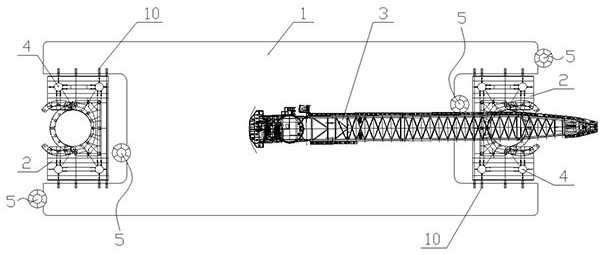

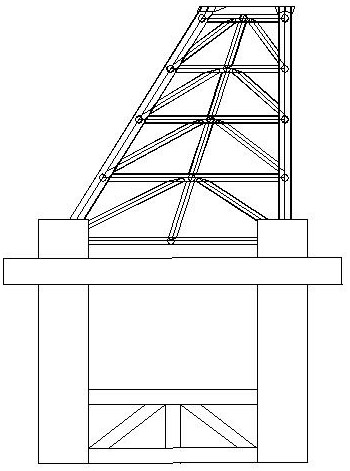

[0054] A steel pipe pile construction system based on a floating pile stabilization platform of the present invention comprises a floating pile stabilization platform 1, a floating crane vessel 18, a split truss 2, a compensator 10 and a steel pipe pile 7; the specific structure is as follows Figure 1~21 As shown, an auxiliary crane 3 is provided in the middle of the upper surface of the floating pile stabilization platform 1, and a main crane 6 is provided on one side of the upper surface of the floating crane vessel 18; There are also several compensators 10 arranged symmetrically on the left and right sides on both sides of the head and tail, and each compensator 10 is arranged horizontally along the length direction of the U-shaped mouth of the floating pile stabilization platform 1, and its adjustment ends are all facing the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com