Crucible with heat conduction device

A technology of crucible and cooling rod, which is applied in the field of display device production, can solve problems such as poor heat transfer, and achieve the effect of improving evaporation efficiency and evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

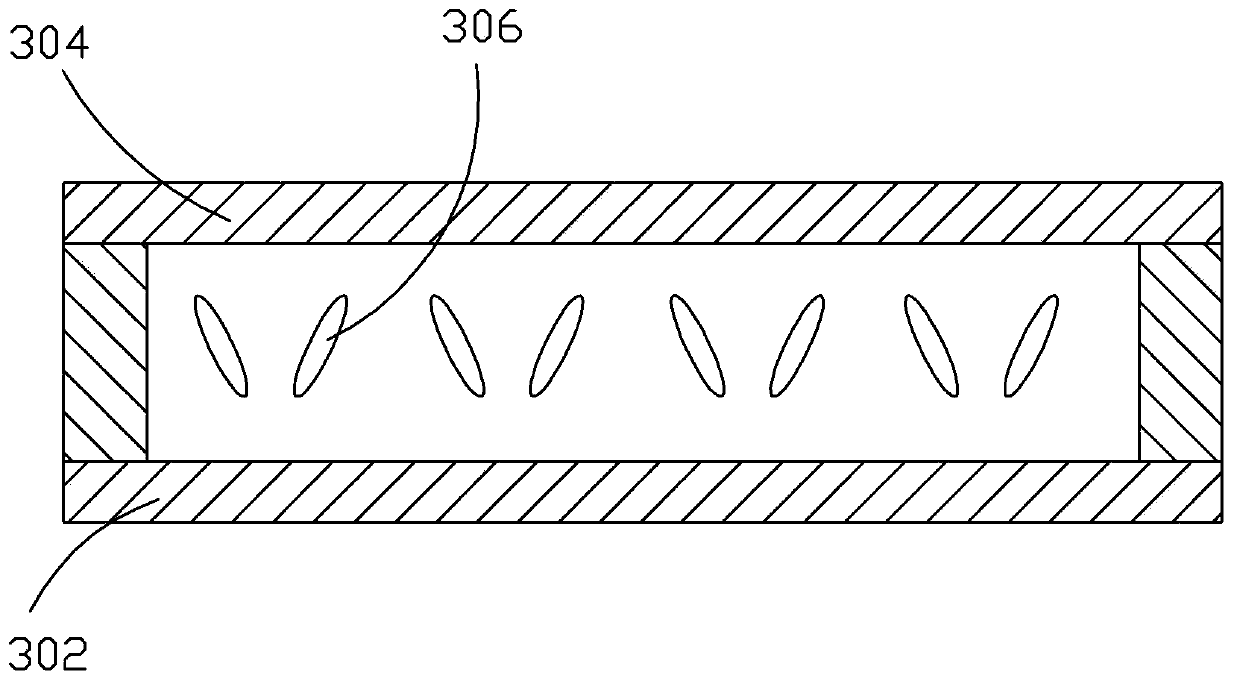

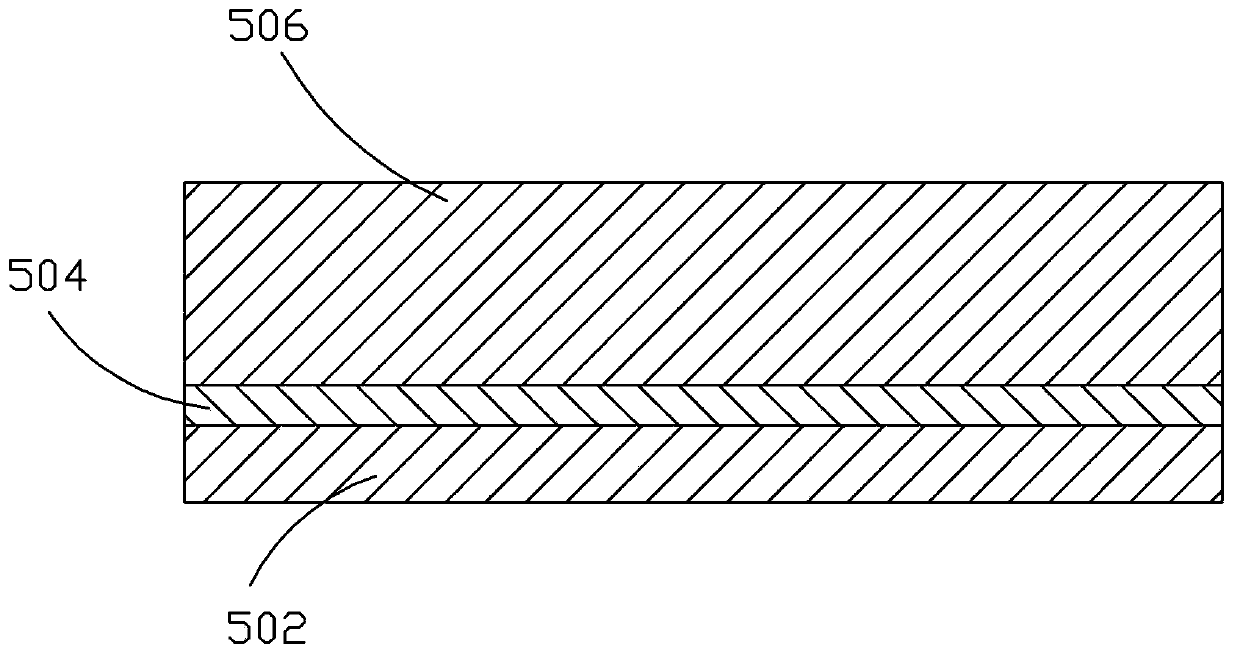

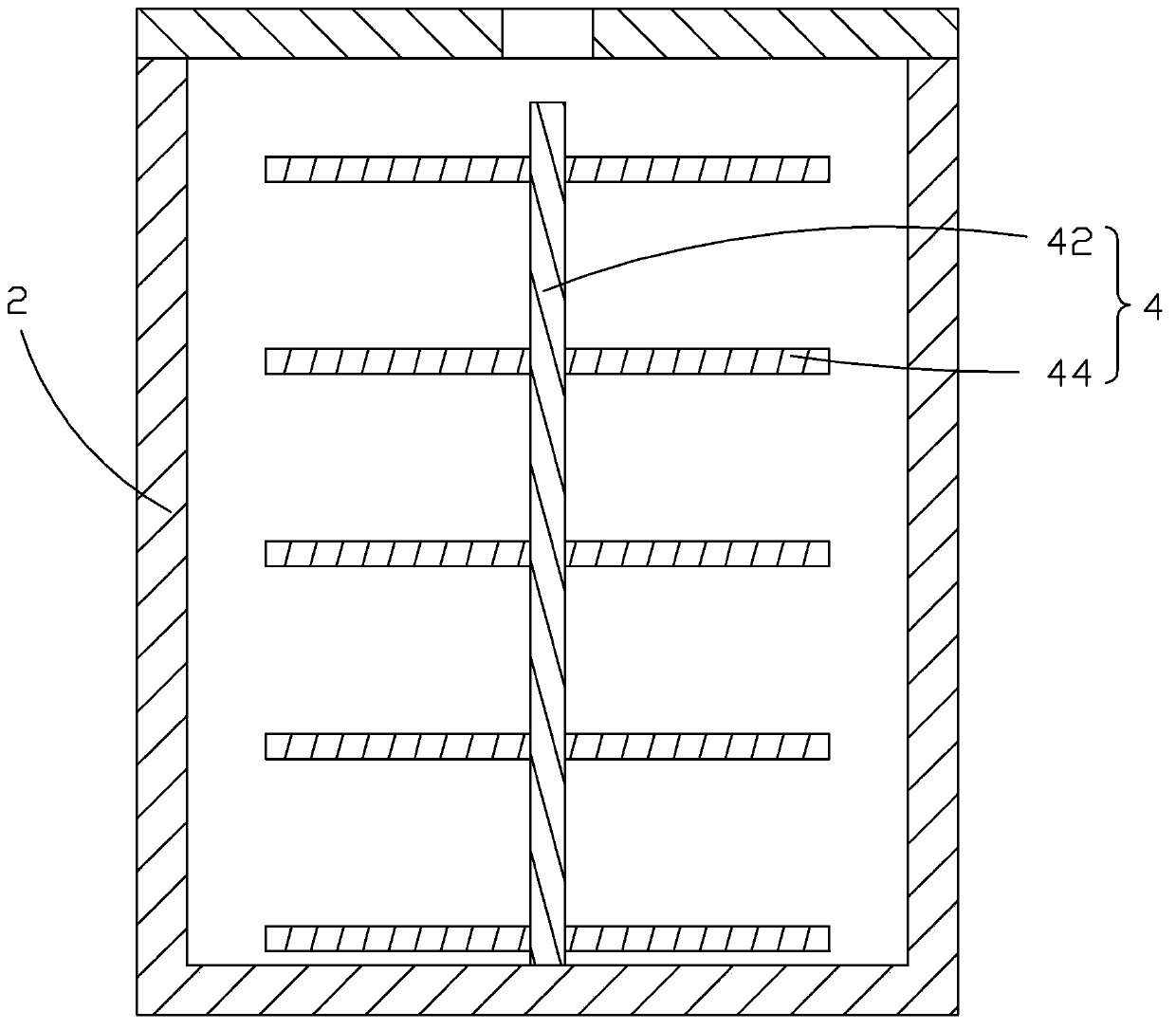

[0035] see image 3 and Figure 4 , the present invention provides a crucible with a heat conduction device, which is used in a coating machine for evaporating organic materials in organic light-emitting diodes, which includes: a crucible body 2 and a heat conduction device 4 arranged in the crucible body 2, the heat conduction device 4 It is tree-shaped, and it includes a heat dissipation trunk 42 and several layers of heat dissipation branches 44 arranged on the heat dissipation trunk 42. Each layer of heat dissipation branches 44 includes several branch units 442, and the branch units 442 are formed by the heat dissipation trunk 42. The outer surface of the crucible is extended outwards. The present invention transmits heat to all directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com