Patents

Literature

32 results about "Threshold stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress threshold is the ability for you to handle stress at certain levels and what the effects might be if you go over the threshold limit. A low threshold to stress means anything minor you overreact or become irrational. A high threshold to stress means you have enough patience and practice to ensure that the stress does not get to you.

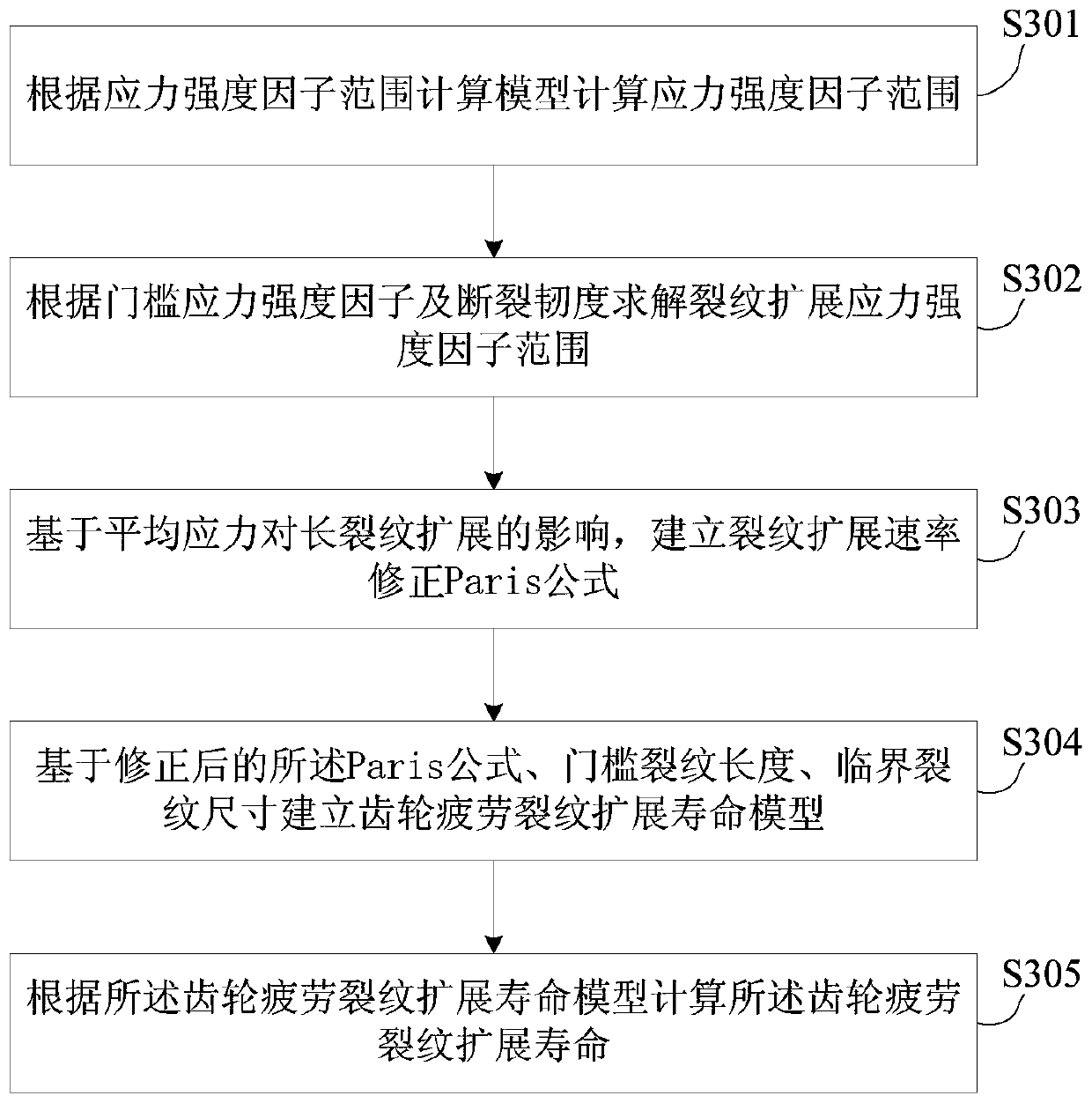

Gear bending fatigue life forecast method and apparatus

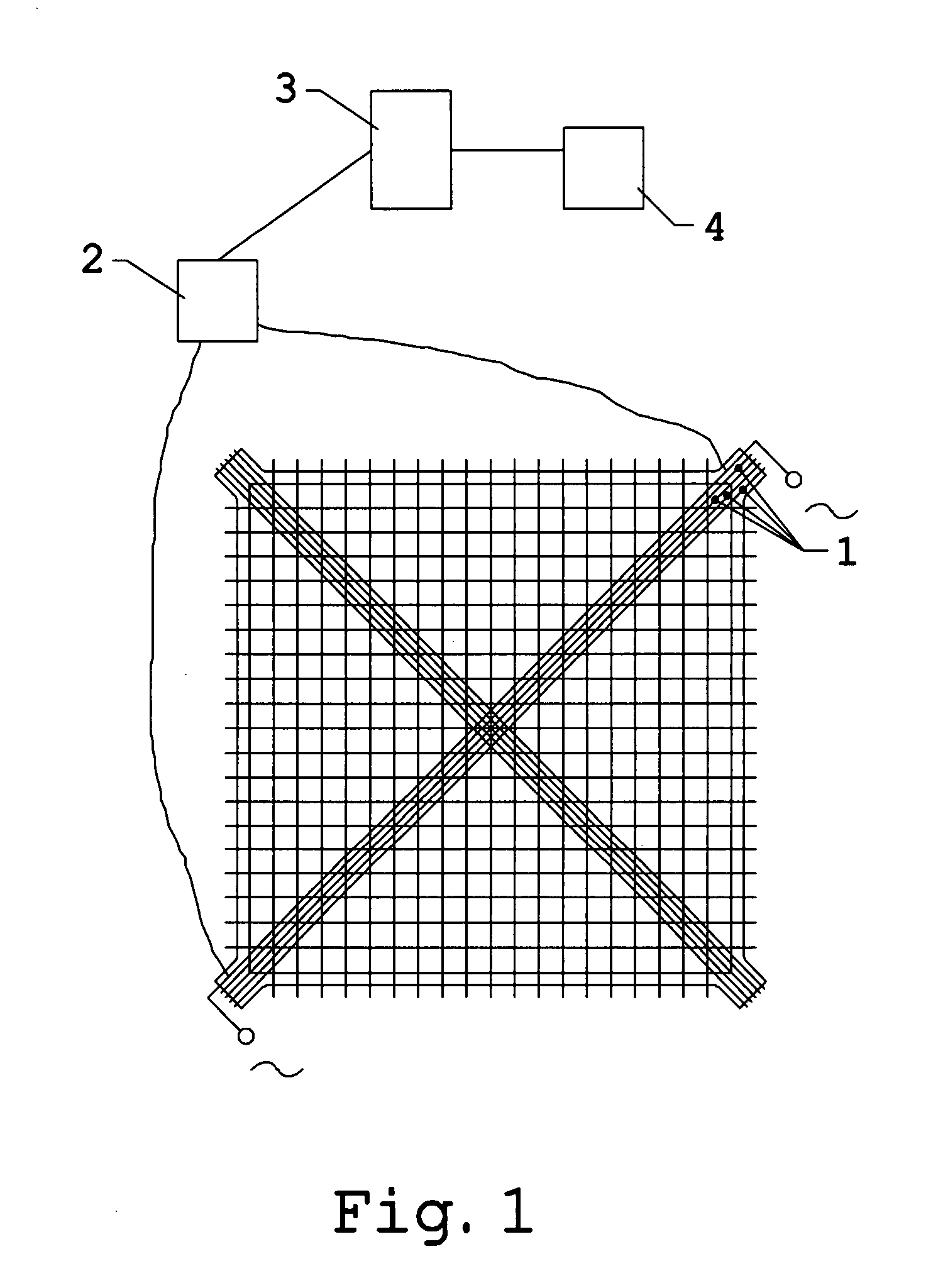

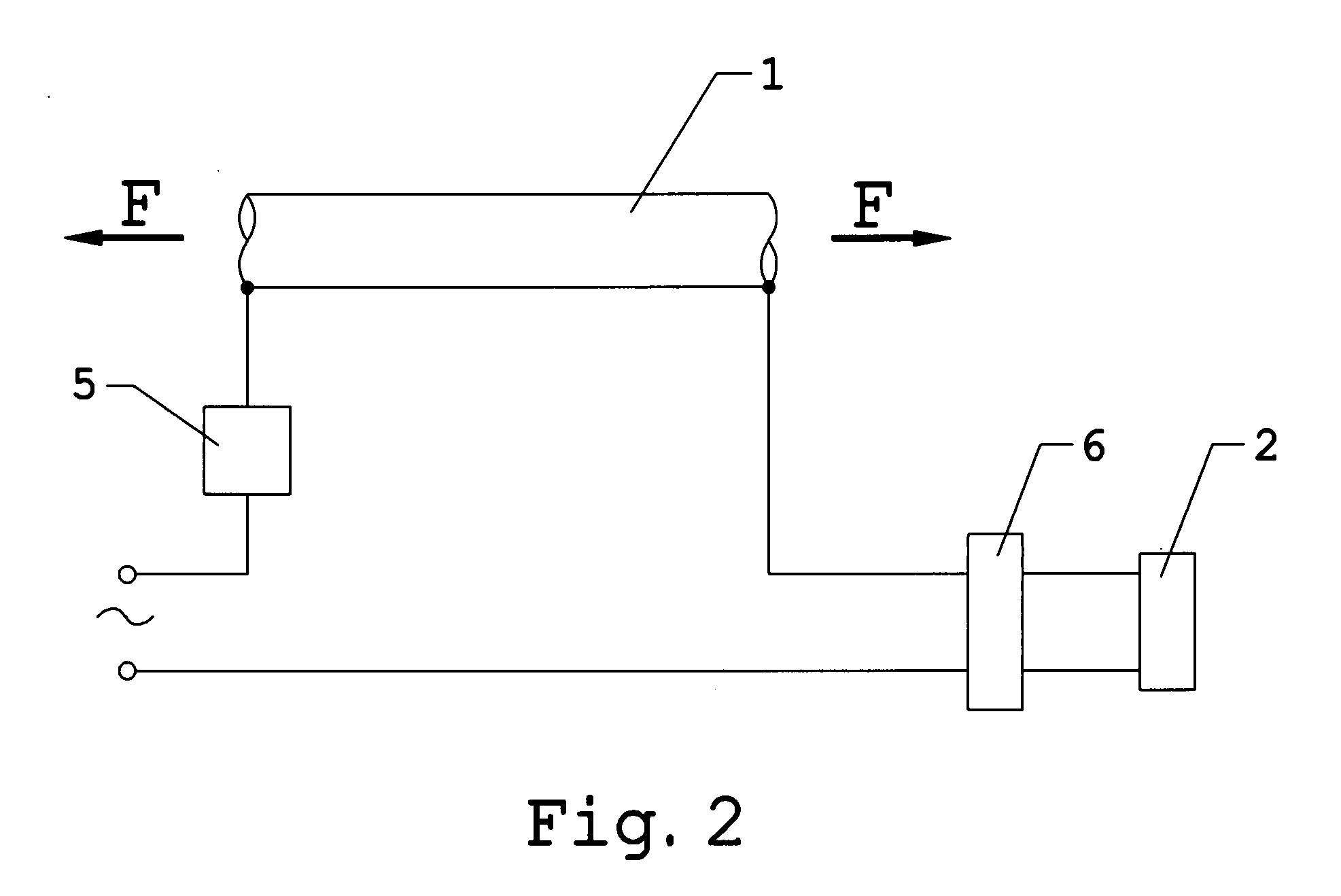

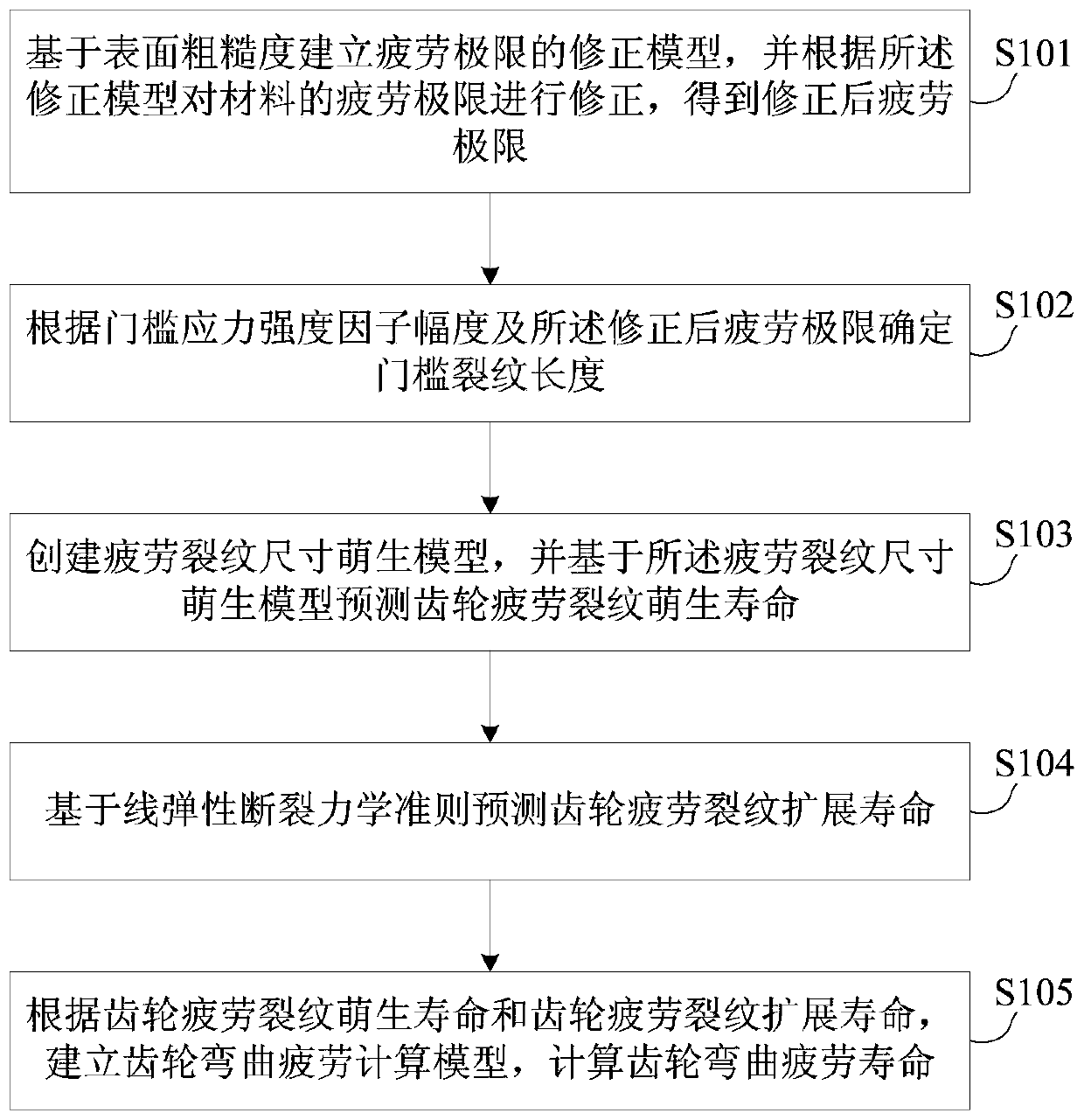

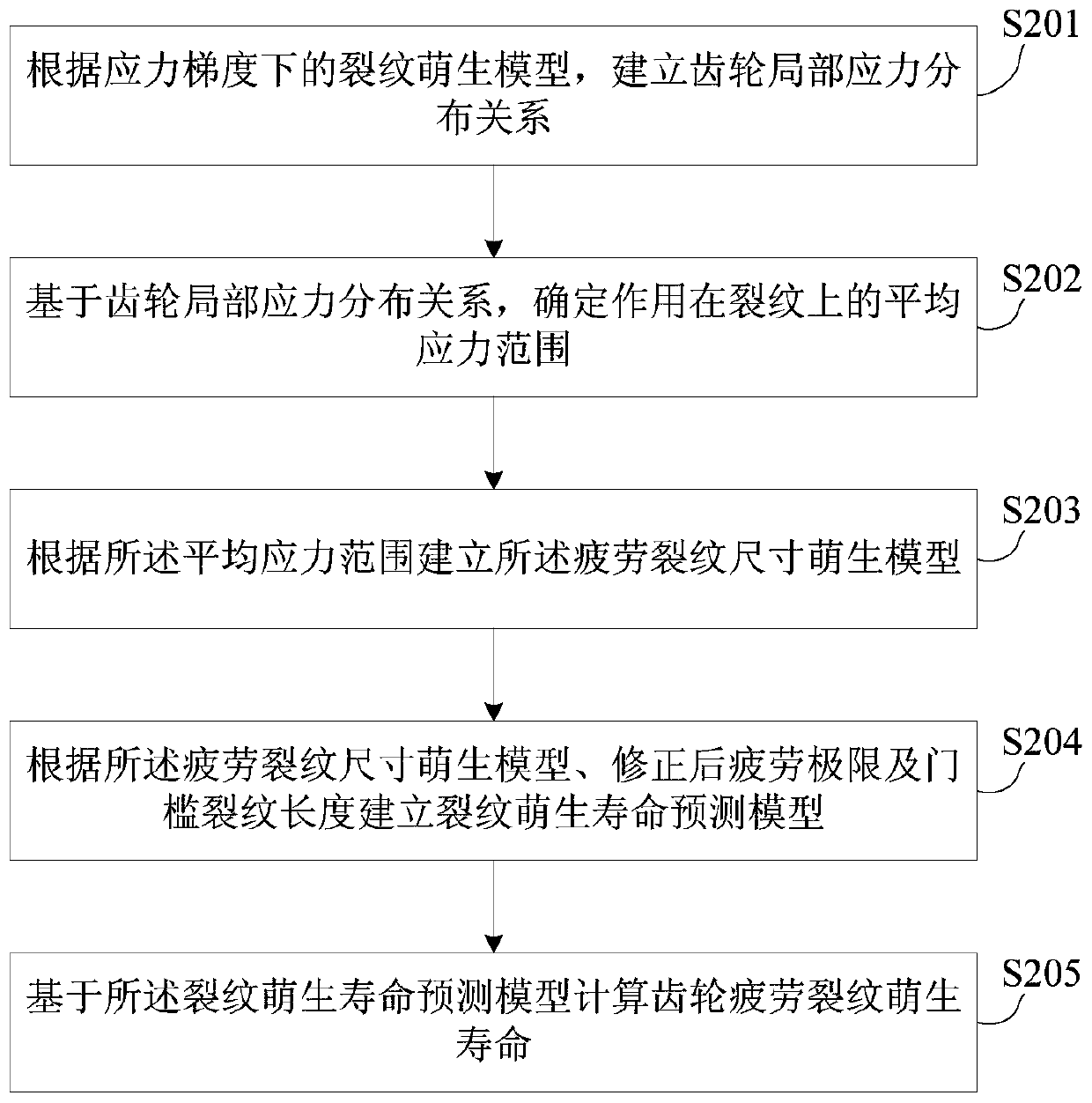

ActiveCN106886663ASimplify the operating life prediction processPredicting Flexural Fatigue LifeGeometric CADDesign optimisation/simulationGuidelineSurface roughness

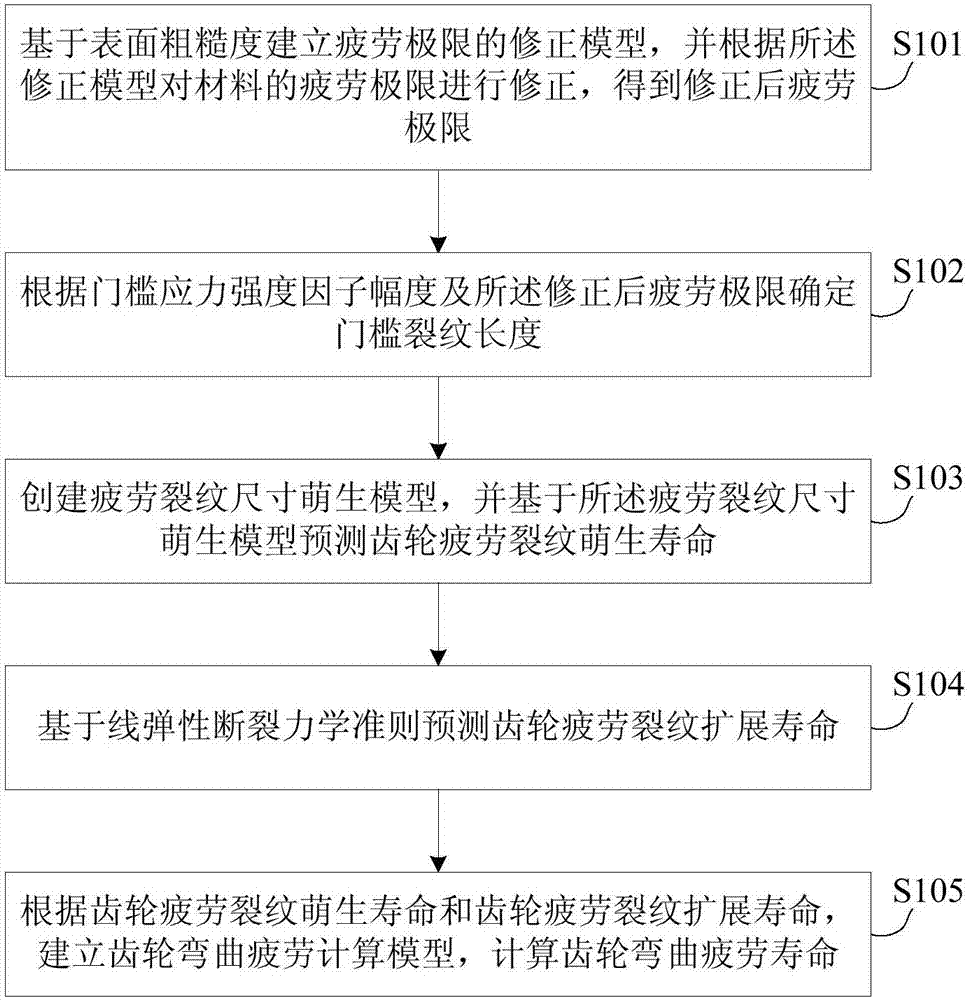

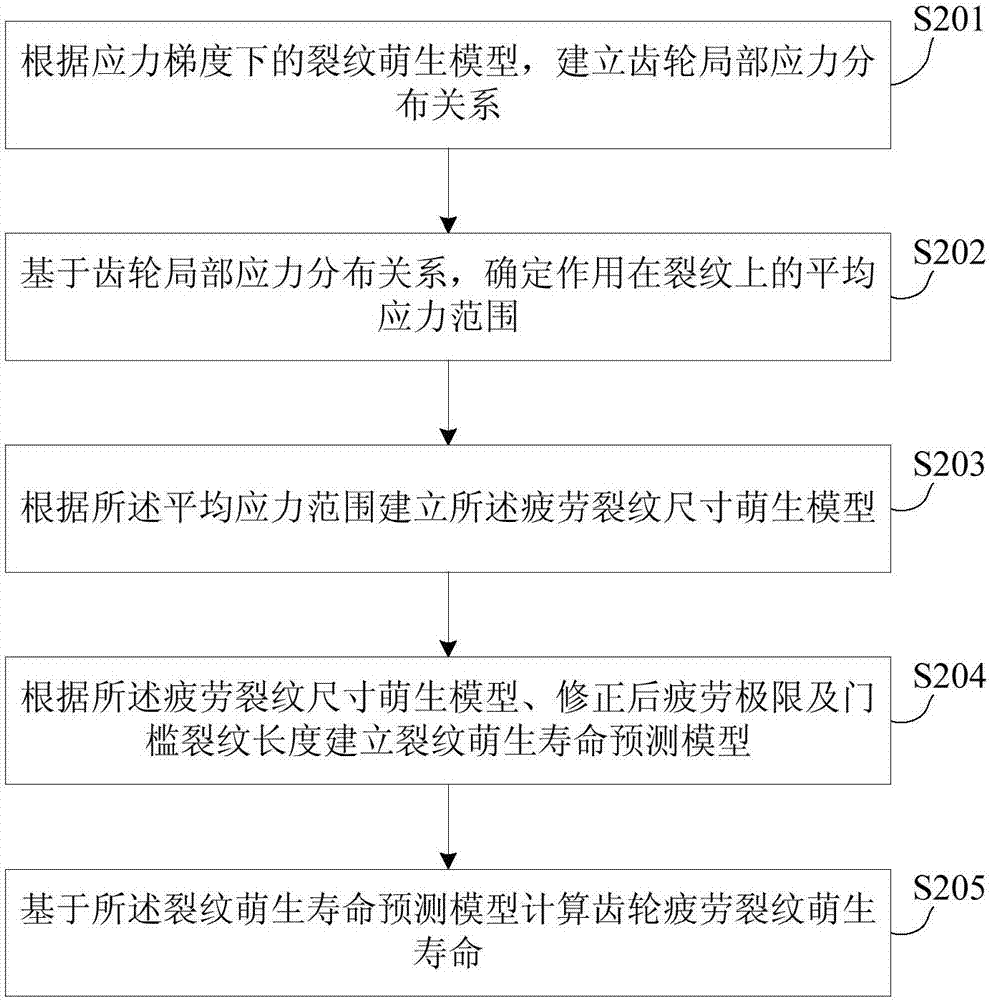

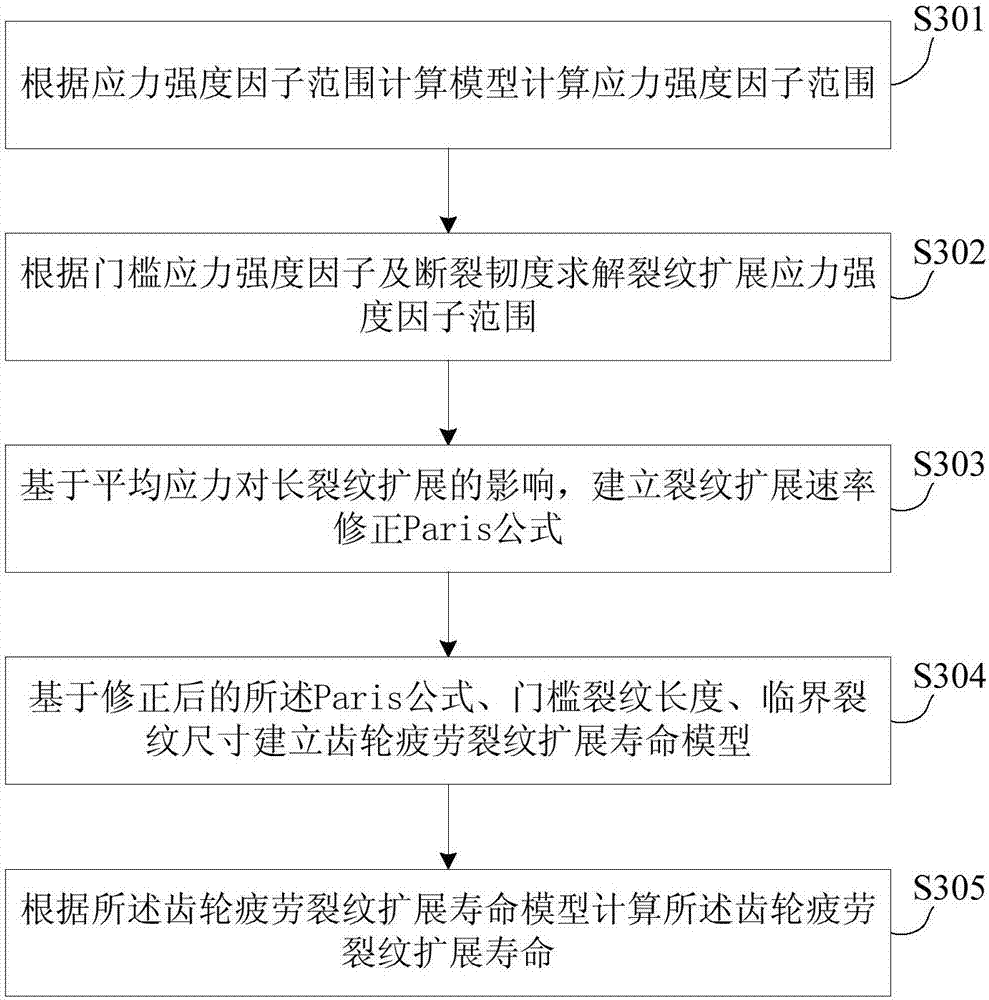

The invention provides a gear bending fatigue life forecast method and a device. The gear bending fatigue life forecast method comprises the steps that a fatigue limit amendment model is built based on the surface roughness, and the fatigue limit of materials is amended according to the amendment model, the fatigue limit after the amendment is obtained; the threshold crack length is determined according to the threshold stress strength factor range and the amended fatigue limit; a fatigue crack size initiation model is created, and gear fatigue crack initiation life is forecasted based on the fatigue crack size initiation model; gear fatigue crack propagation life is forecasted based on the linear elastic fracture mechanics guidelines; according to the gear fatigue crack initiation life and gear fatigue crack propagation life, a gear bending fatigue calculation model is built, to calculate the gear bending fatigue life.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Crack arrest method of alloy surface fine crack crack arrest method and device thereof

InactiveCN101239432AImprove efficiencyRaise the Fatigue ThresholdLaser beam welding apparatusLacquerPulse energy

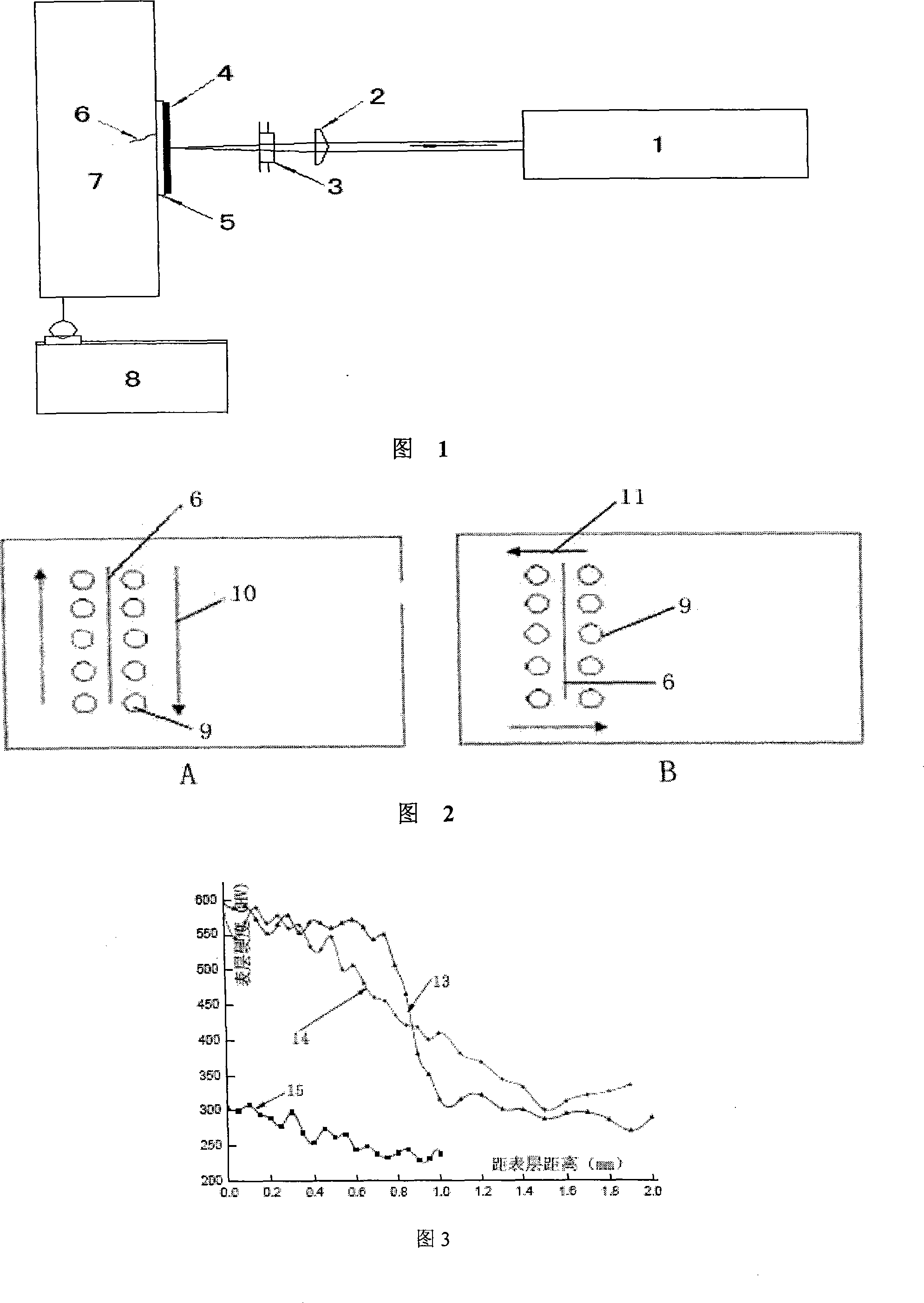

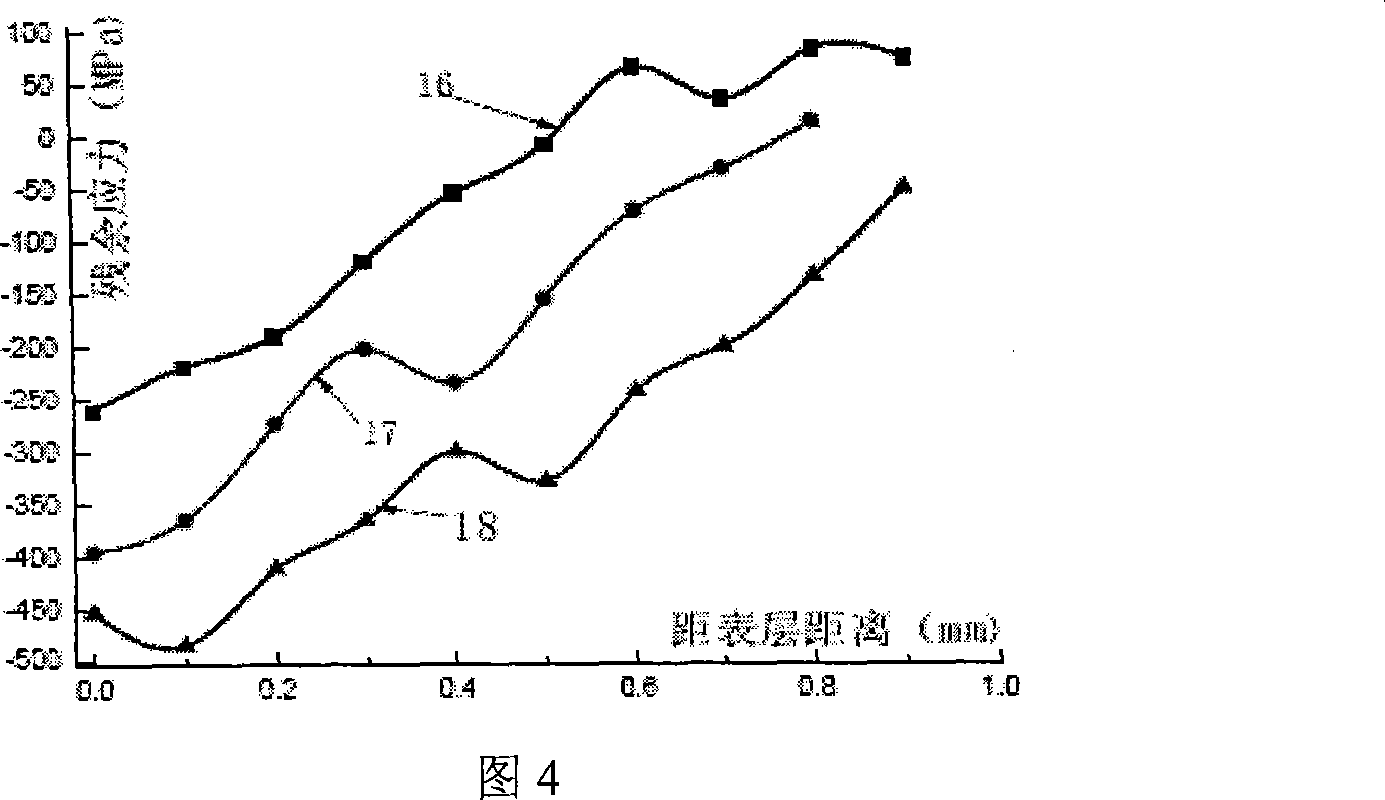

A crack arrest process and device thereof for removing fine cracks on alloy surfaces, relates to laser impulse processing application technique field. Oxide layers and pollutants on alloy surfaces which affect surface bonding force are removed to obtain good glue-joint strength and permanent stability; a flexible film is adhered to the alloy surface as a crack arrest patch, and a layer of black lacquer coating is applied on the crack arrest patch; laser pulse with following parameters: pulse energy of 15-40J, pulse width of 20-30ns, light spot size of 4-10mm, repetition frequency of 0.5-10Hz is selected to performing laser impact crack arrest according to damage status of the cracks; laser crack arrest is performed by selecting crack arrest route, and crack effects are inspected by using no-damage technique during crack arrest process. The invented method and device can increase alloy surface fatigue threshold value, the existing of residual compressive stress on metal surface after laser impulse enhances fatigue threshold stress on material surface greatly.

Owner:JIANGSU UNIV

Method for measuring several critical strain values of metal membrane in flexible substrate

InactiveCN1924564AReduce sudden failurePreparing sample for investigationMaterial strength using tensile/compressive forcesCurrent loadElectrical resistance and conductance

This invention discloses one current load metal film stretching stress value test describing method, which comprises the following steps: processing current load and micro force stretching on the good metal film of interface; during this process recording the metal film stress curve and resistance change curve; acquiring the crack percentage stress curve through micro analysis by observing metal film. The current load metal film and flexible base board system invalid threshold system is composed of three threshold stress, such as the stress from resistance change to stress curve from linear phase to non-linear conversion; micro crack percentage stress curve back reducing as zero theory into threshold extension stress; resistance change to stress curve resistance runaway time into threshold crack unstable stress.

Owner:山东合创涂层技术有限公司

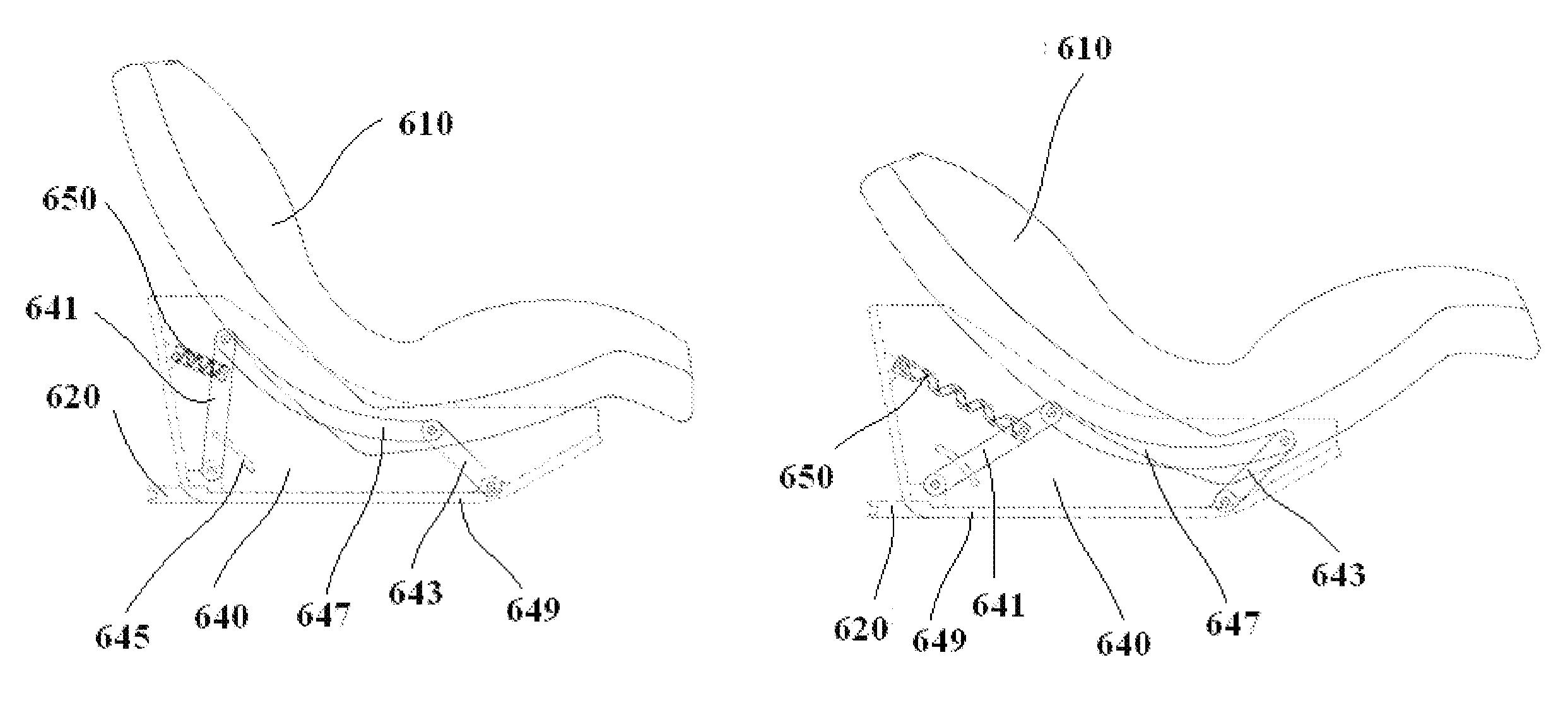

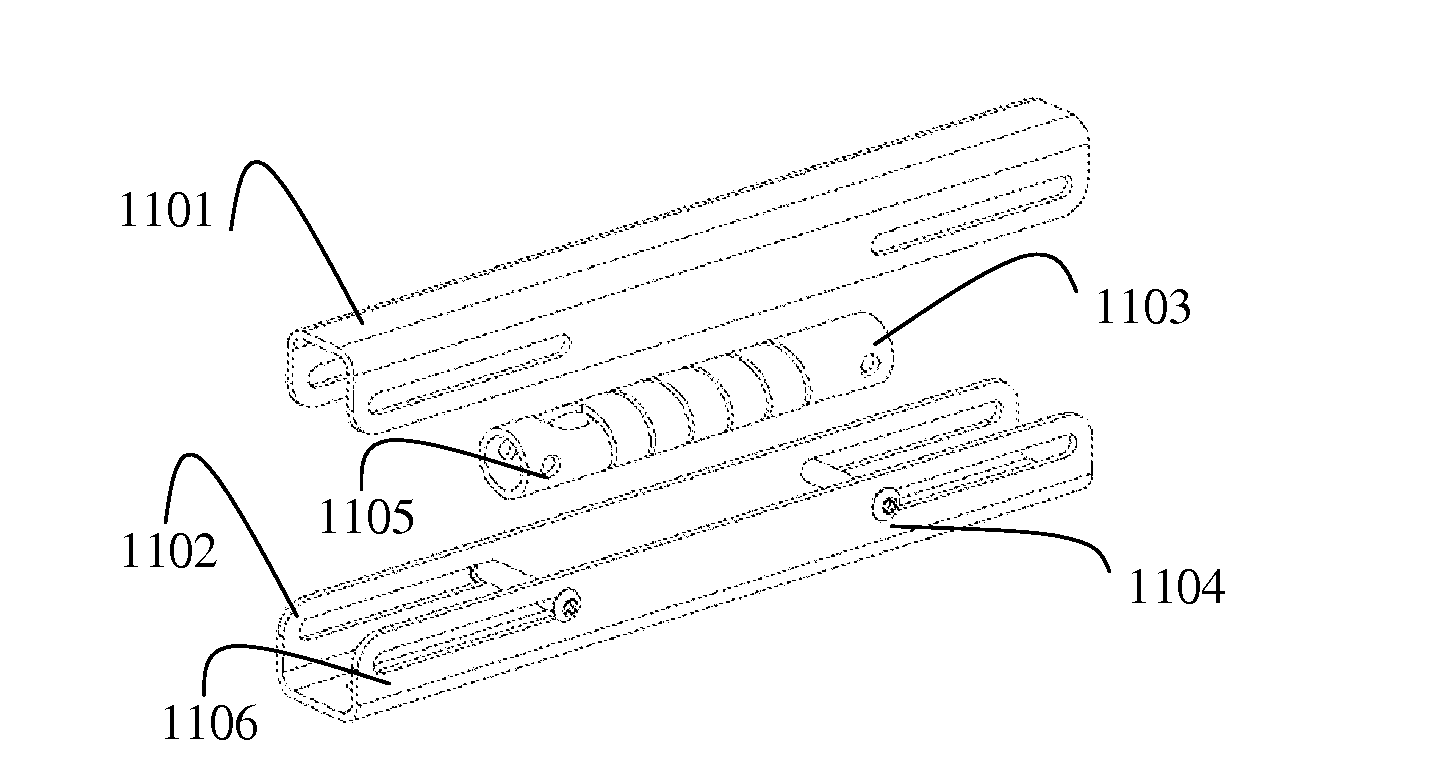

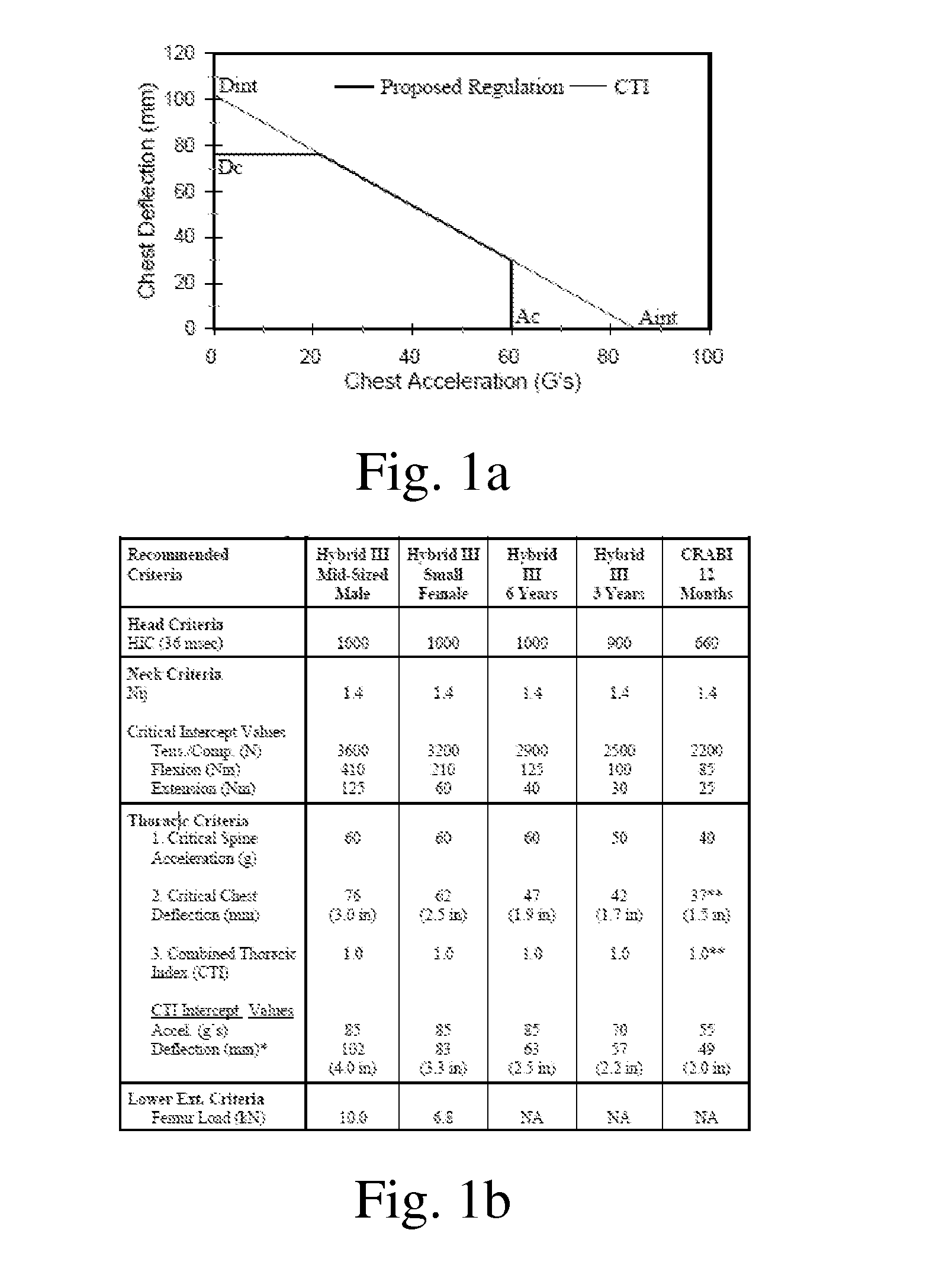

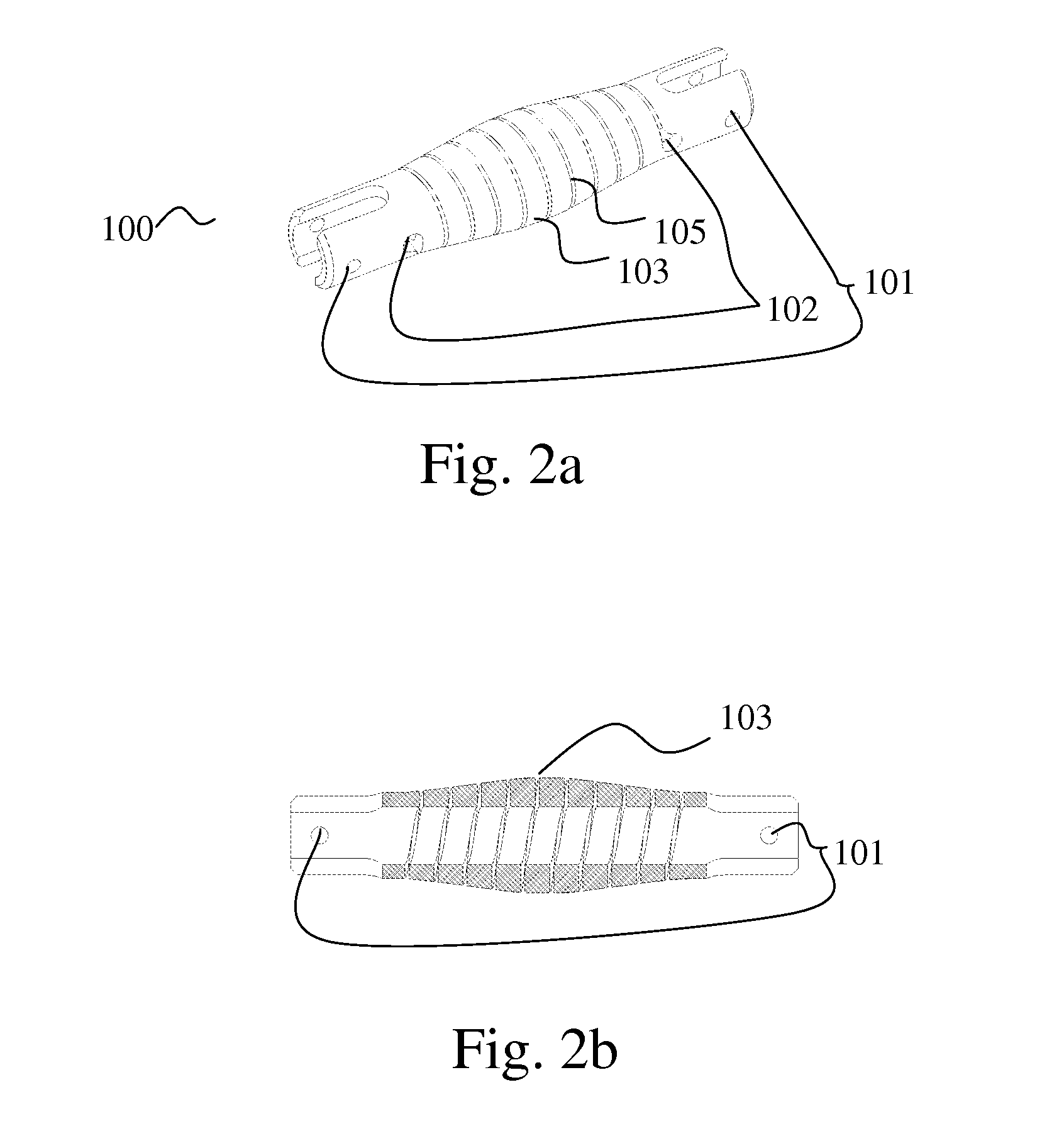

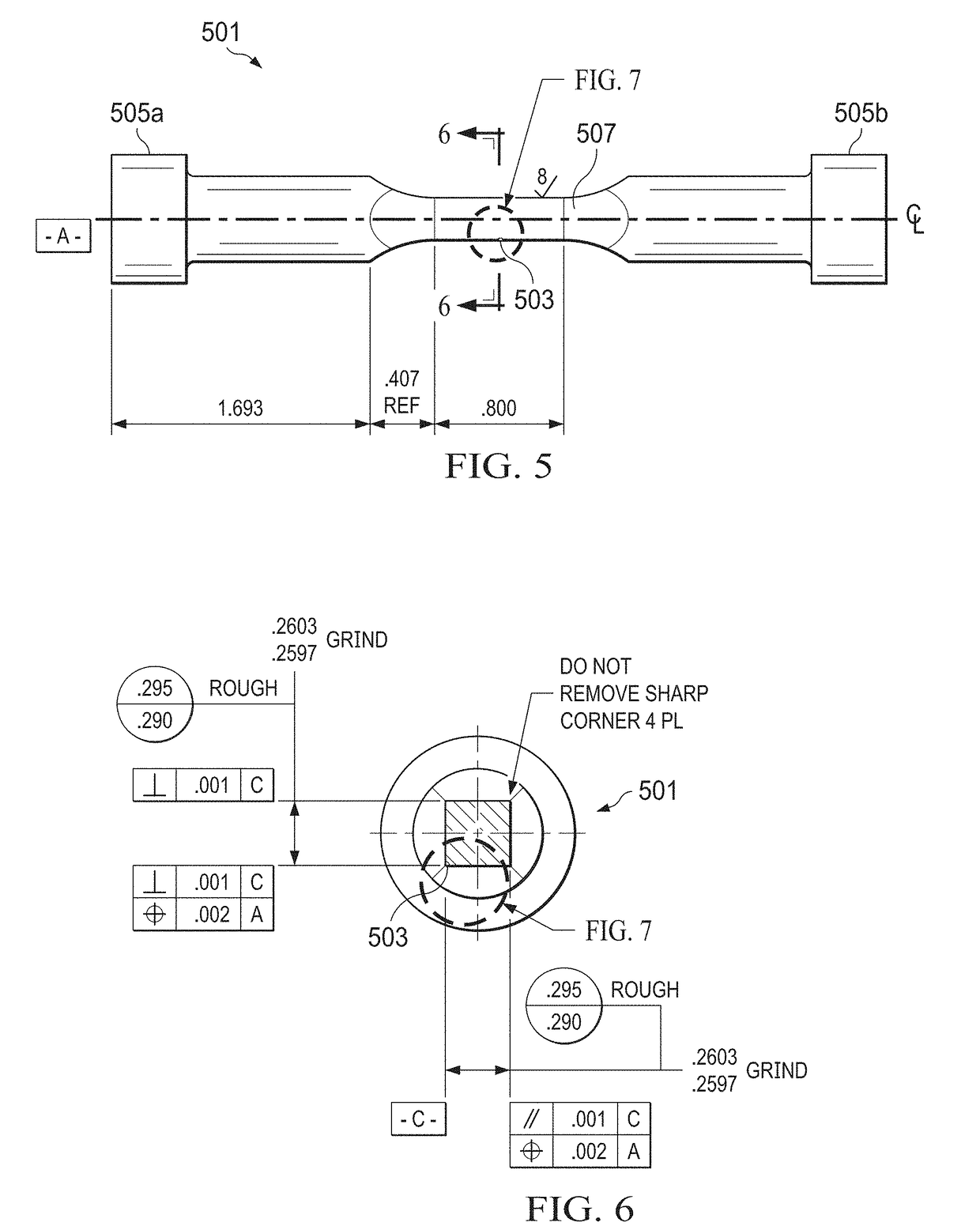

Safety seat

An energy absorbing device for carrying a passenger seat; the device comprises a base fixed to a vehicle; a member displaceable from base; at least one energy-absorbing arrangement interconnecting base and displaceable member. The energy-absorbing arrangement comprises a plastically deformable absorbing element in response to stresses greater than a predetermined threshold stress. In some embodiments the plastically deformable absorbing element is a helically configured ribbon having spaced-apart ribbon laps. In other embodiments the plastically deformable absorbing element is compressible, and / or extendable. A method of attenuating the acceleration applied to a passenger due to impact is disclosed; the method comprises steps of: providing an energy absorbing device fixedly attaching the base to the vehicle; fixedly attaching the passenger seat to the base; accidently applying the impact to the vehicle; displacing the displaceable member relative to the base; attenuating the effect of the impact on the passenger.

Owner:MOBIUS PROTECTION SYST

Safety seat

ActiveUS20140239684A1Reduce shockReduce the overall heightVehicle seatsPedestrian/occupant safety arrangementEngineeringThreshold stress

An energy absorbing device for carrying a passenger seat; the device comprises a base fixed to a vehicle; a member displaceable from base; at least one energy-absorbing arrangement interconnecting base and displaceable member. The energy-absorbing arrangement comprises a plastically deformable absorbing element in response to stresses greater than a predetermined threshold stress. In some embodiments the plastically deformable absorbing element is a helically configured ribbon having spaced-apart ribbon laps. In other embodiments the plastically deformable absorbing element is compressible, and / or extendable. A method of attenuating the acceleration applied to a passenger due to impact is disclosed; the method comprises steps of: providing an energy absorbing device fixedly attaching the base to the vehicle; fixedly attaching the passenger seat to the base; accidently applying the impact to the vehicle; displacing the displaceable member relative to the base; attenuating the effect of the impact on the passenger.

Owner:MOBIUS PROTECTION SYST

Method for constructing forming limit stress diagram of metal sheet

InactiveCN106802256AEasy accessAccurately obtainedPreparing sample for investigationMaterial strength using tensile/compressive forcesTest sampleMetal sheet

Owner:SHOUGANG CORPORATION

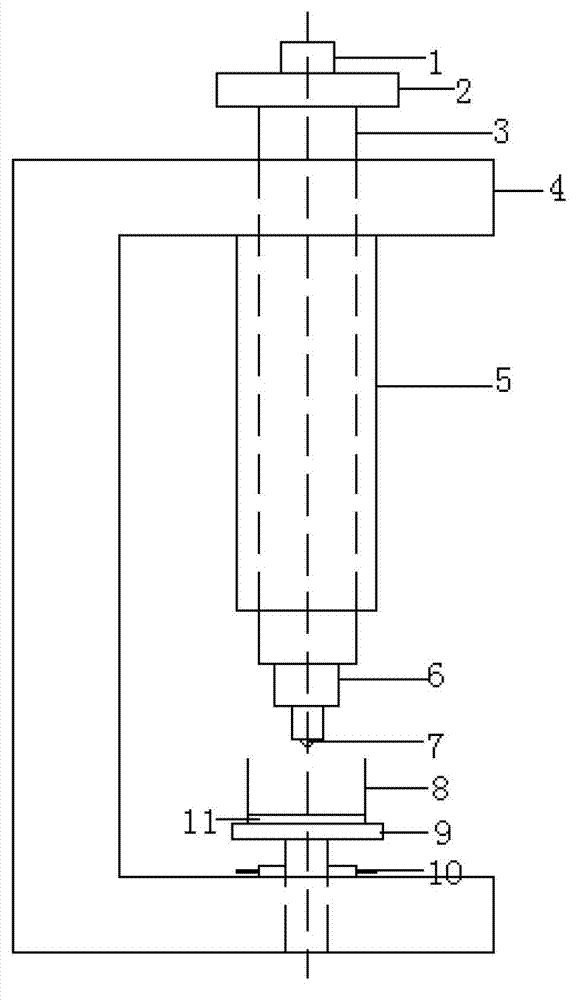

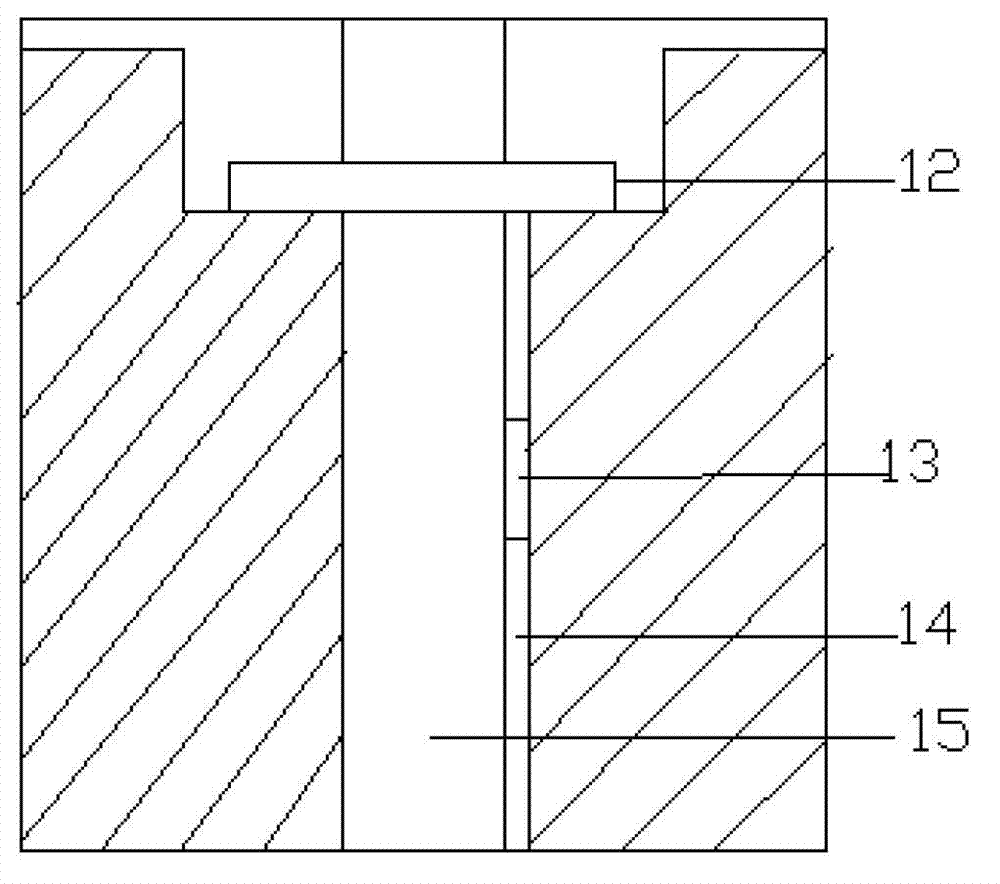

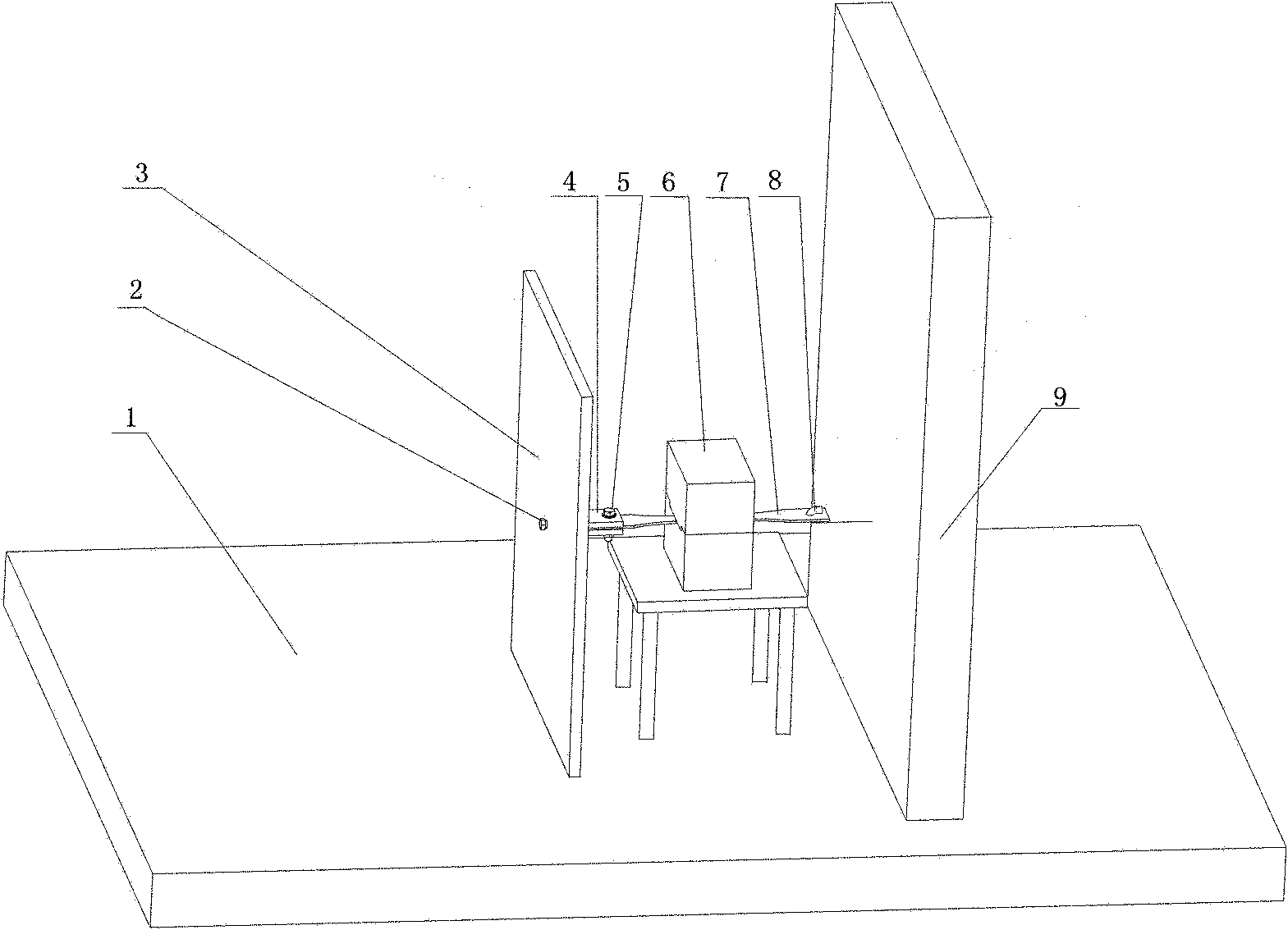

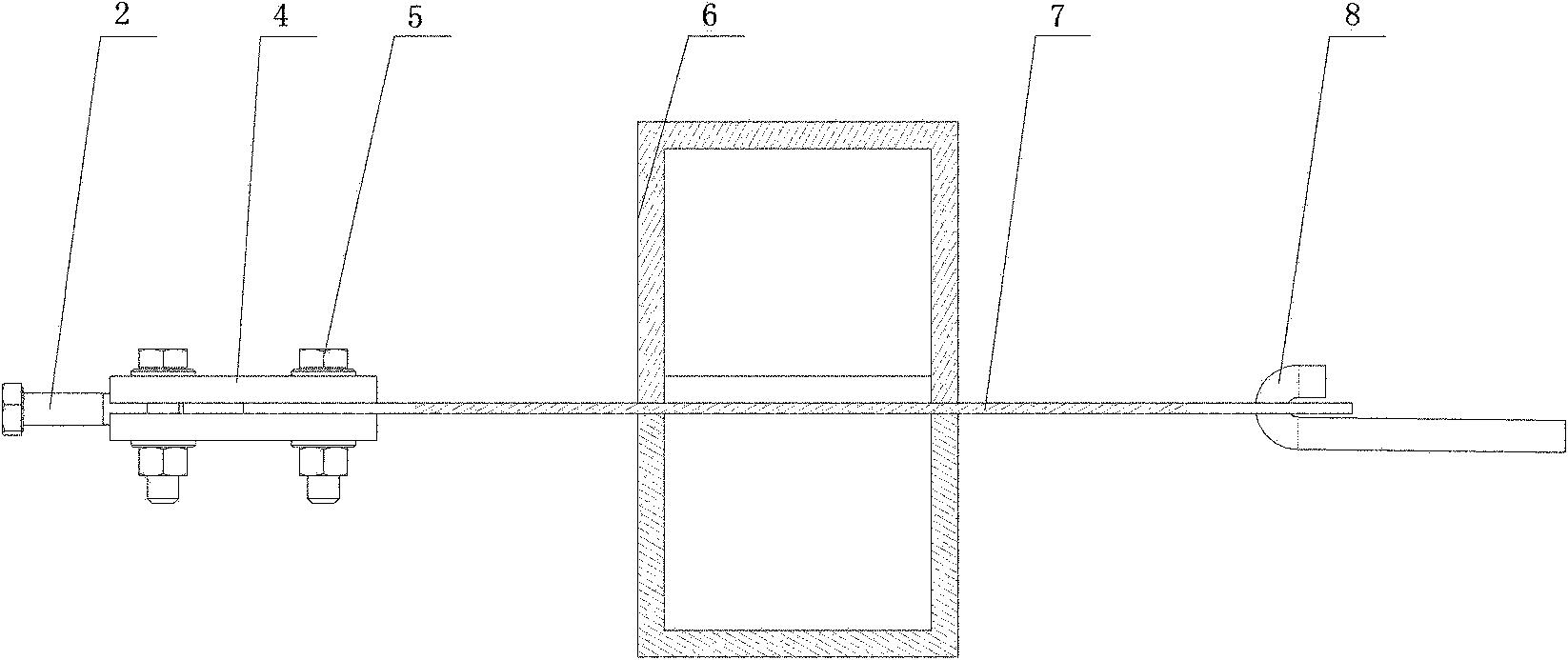

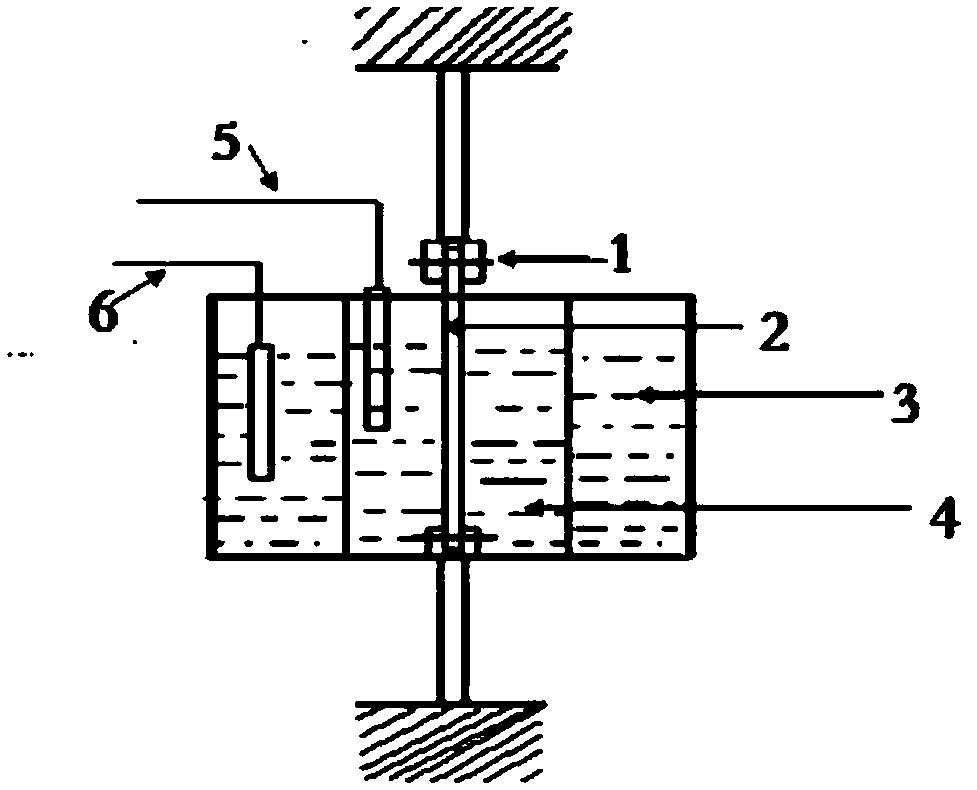

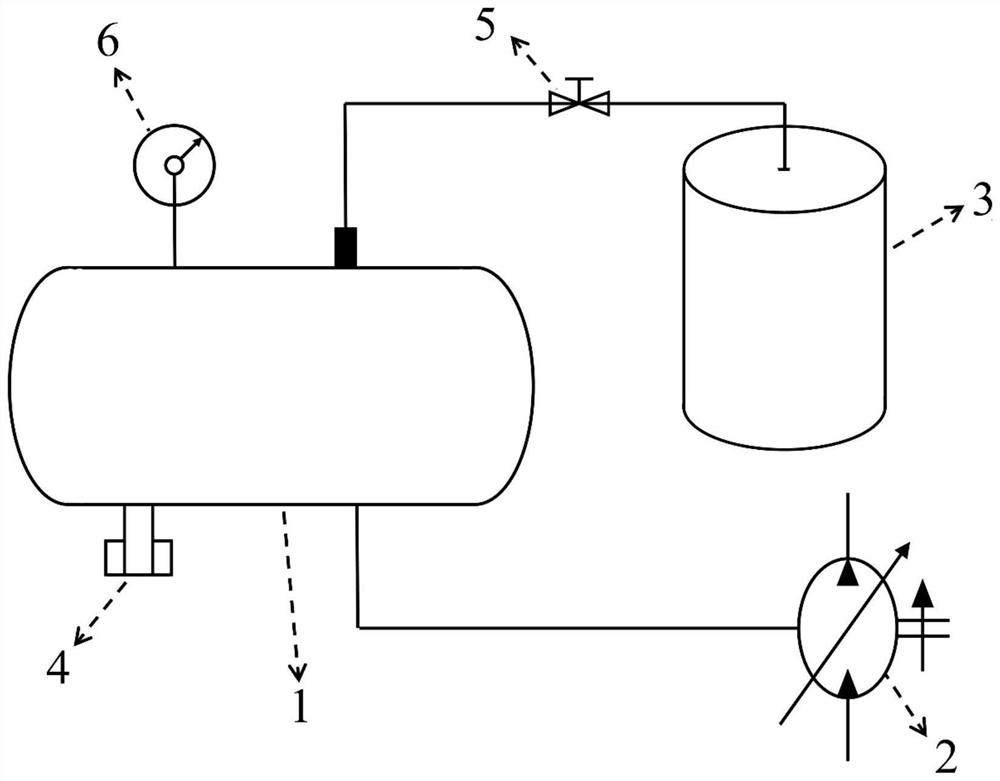

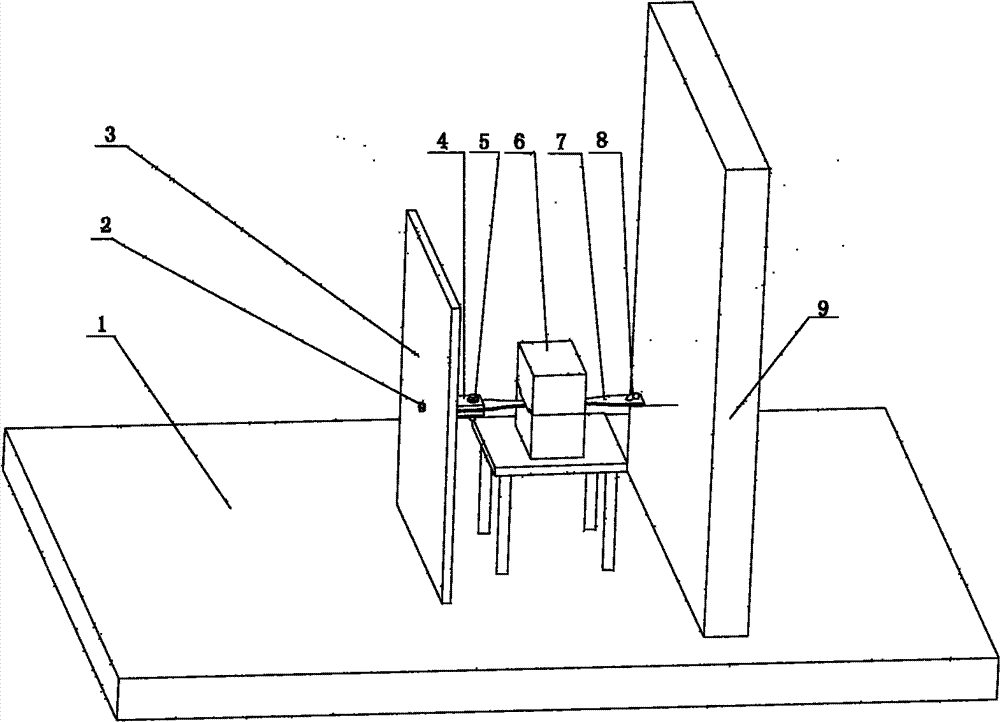

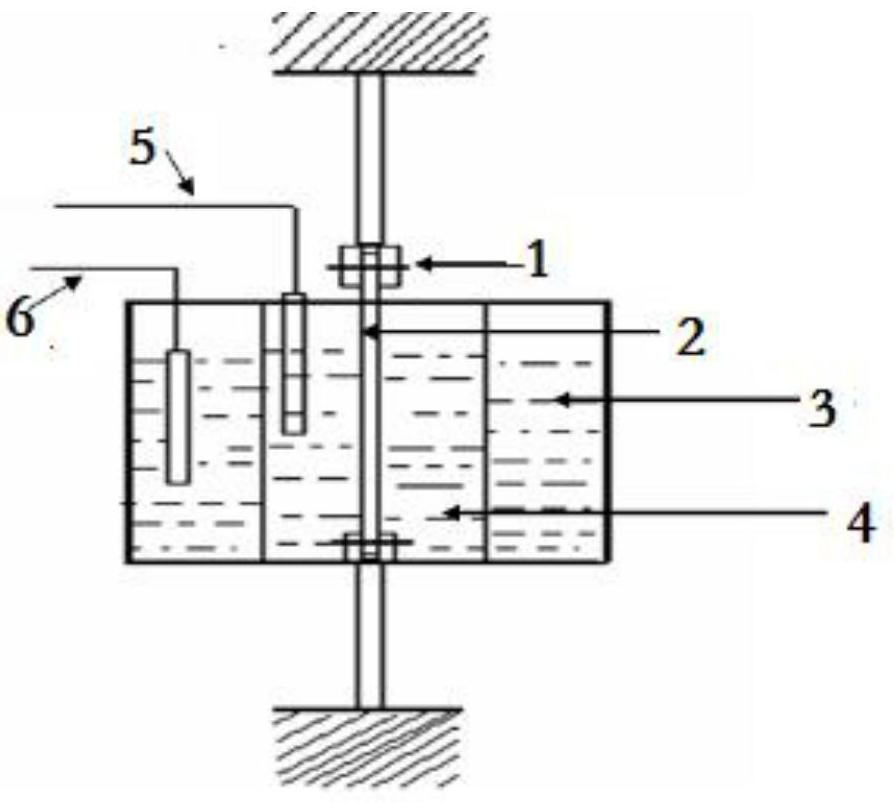

Continuous loading indentation stress corrosion tester and test method therefor

InactiveCN103163035ALow costImprove stabilityWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceHysteresisElectrochemistry

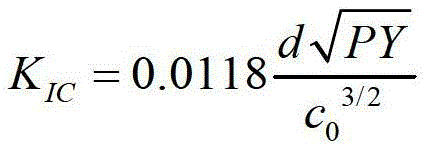

The invention relates to a continuous loading indentation stress corrosion tester and a test method therefor. The continuous loading indentation stress corrosion tester is used for researching hysteresis growth and related mechanical behaviors of material cracks and especially for researching rules of the influence produced by different stresses, environmental mediums and temperatures on crack nucleation and growth, and clearly expounds the rule and the mechanism of material invalidation under the stress-environment coupling condition. The test method comprises the following steps of 1, through contact between a pressure head and a test sample under a certain load, determining fracture toughness of a brittle material, and observing the influence produced by the environment on crack growth under the continuous loading condition, 2, determining threshold stress of hysteresis growth of cracks of the brittle material by radial cracks having certain length under a certain environmental condition, 3, in a solution medium, researching crack growth of a toughness material by indentation, and 4, observing a change of electrochemical parameters in crack growth by connection with an electrochemical workstation. The continuous loading indentation stress corrosion tester can be operated conveniently and simply, realize control of an experimental environment and a load, is especially suitable for long-term loading in different environments, has a simple structure, is convenient for operation and has a large application prospect.

Owner:UNIV OF SCI & TECH BEIJING

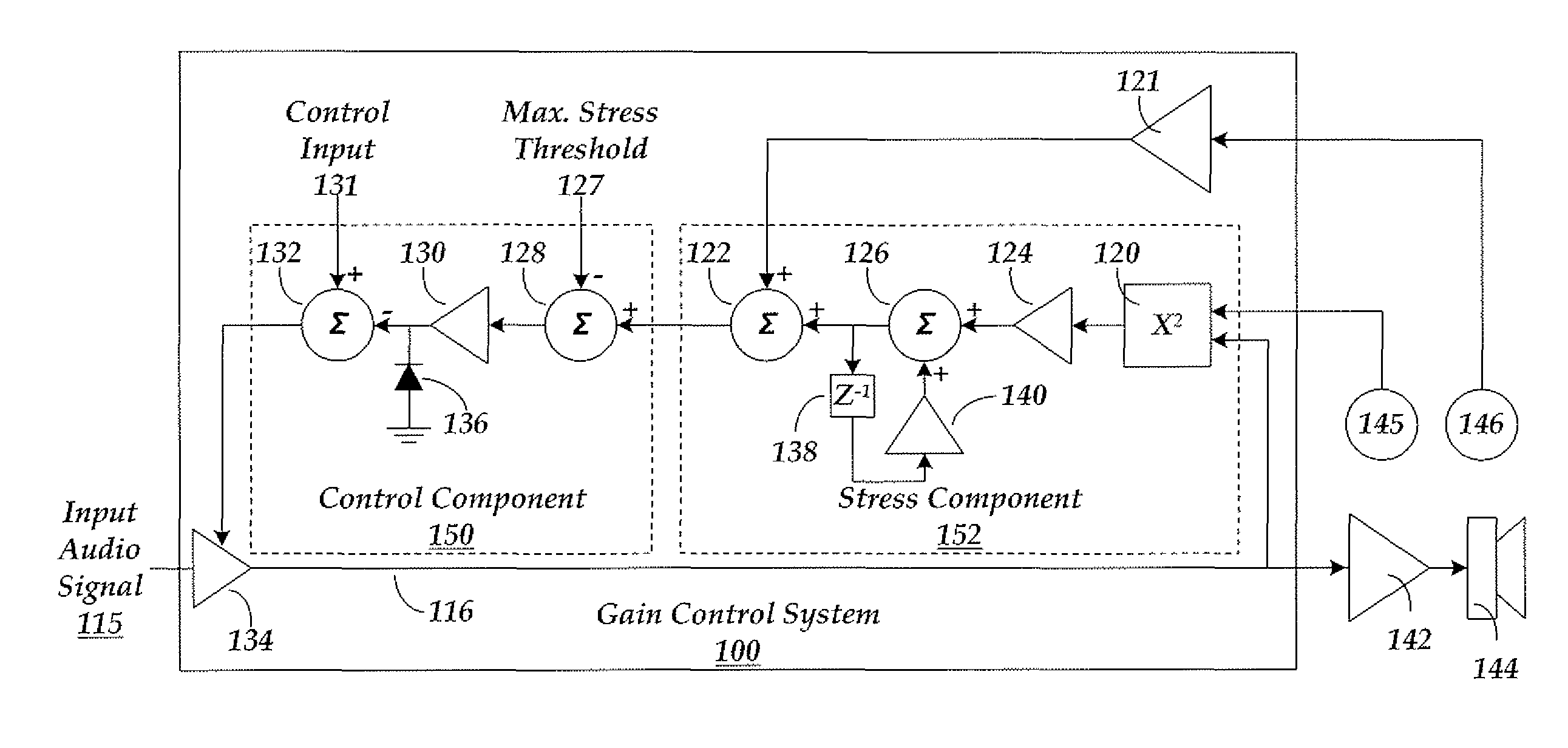

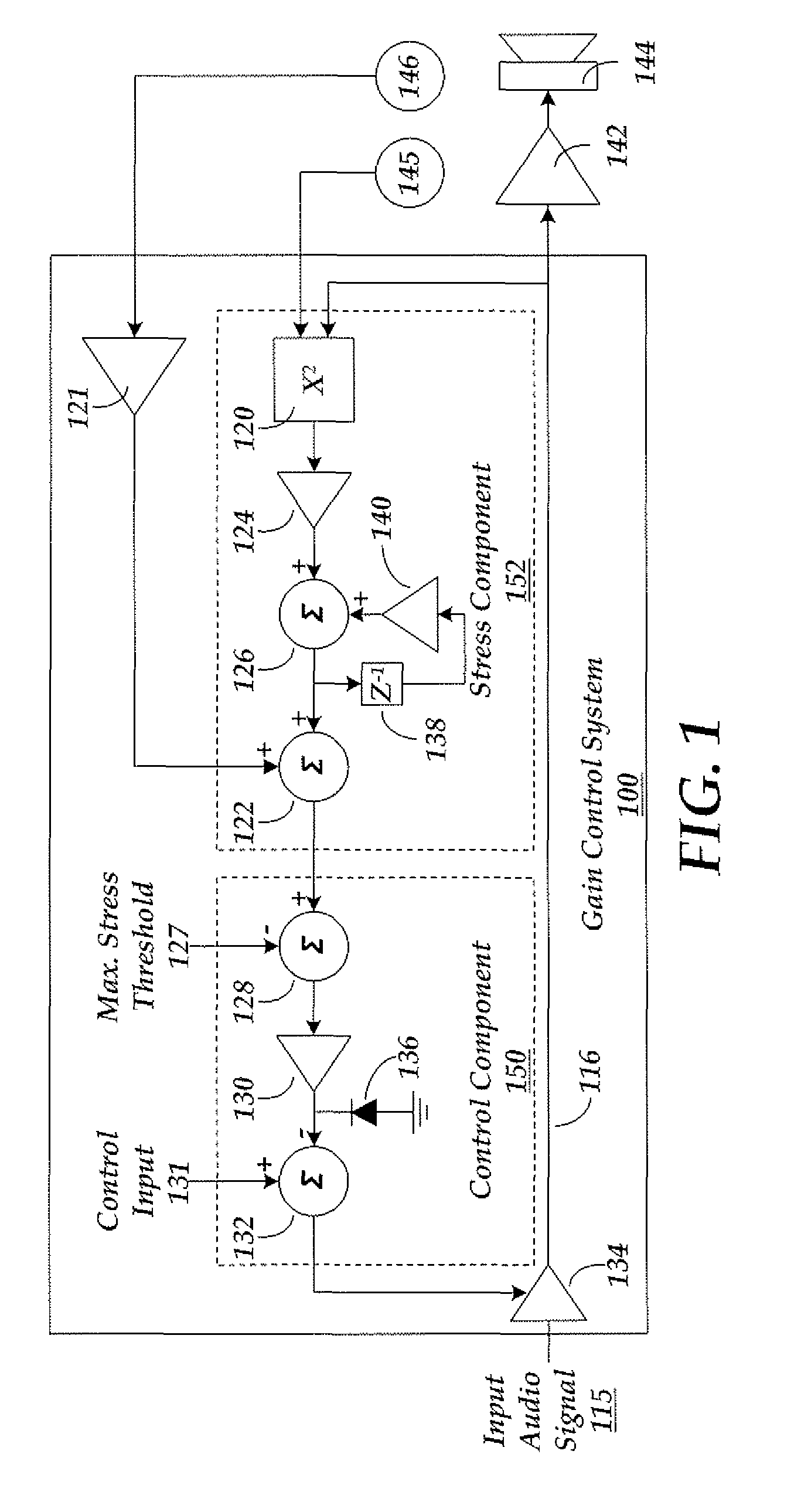

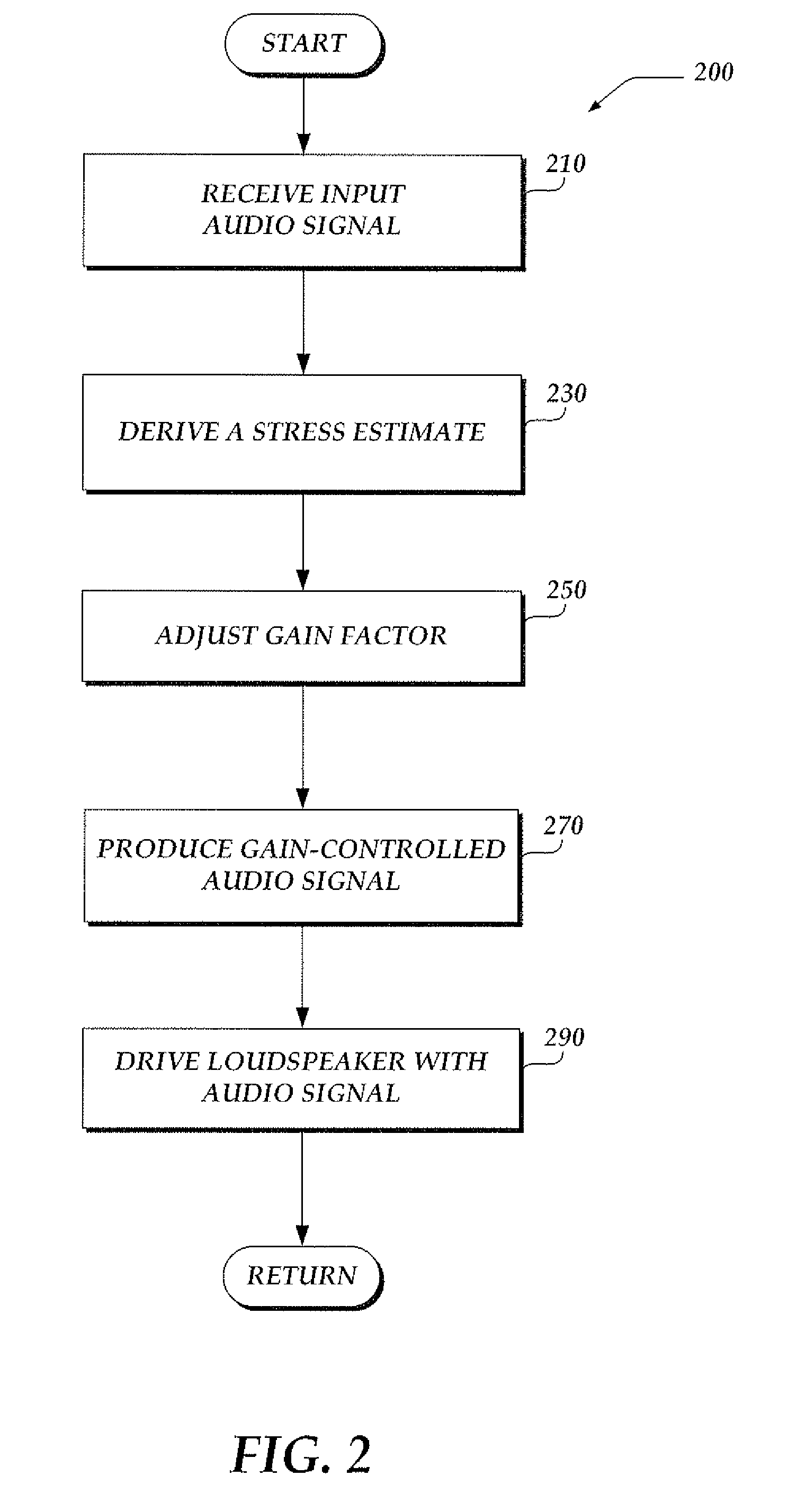

Method to maximize loudspeaker sound pressure level with a high peak to average power ratio audio source

A system is provided to protect a loudspeaker (144) by controlling a level of an applied audio signal. A control signal is generated by applying an input audio signal (115) to the collective operations of a gain control system (100). The gain control system (100) uses the input audio signal (115) in conjunction with at least one parameter to derive an estimated stress associated with the loudspeaker (144). The estimated stress is compared with a protection threshold stress (127). If the protection threshold stress is exceeded, a gain applied by a gain component (134) is selectively adjusted to modify the input audio signal (115). The resulting gain-controlled audio signal (116) is employed to drive the loudspeaker (144).

Owner:HARRIS GLOBAL COMM INC

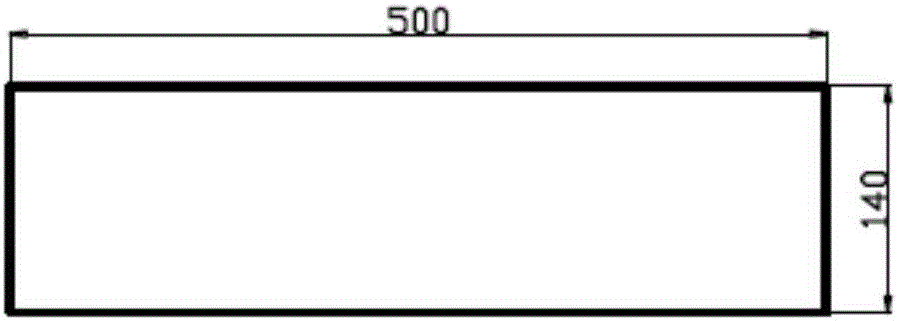

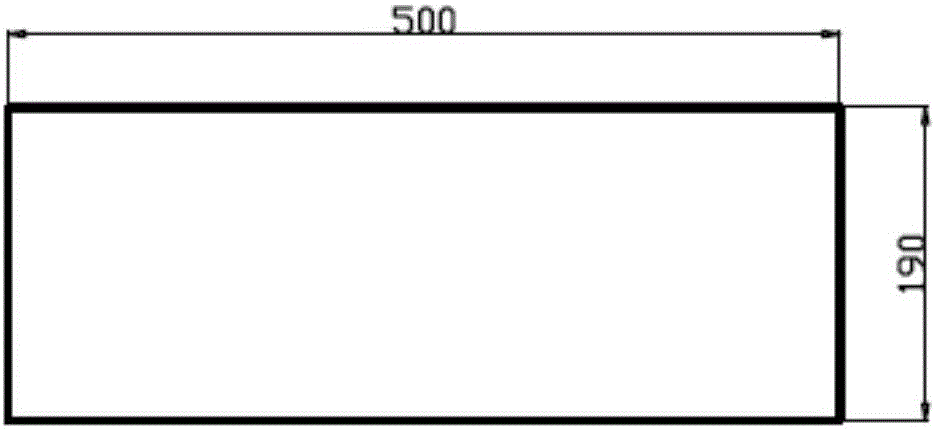

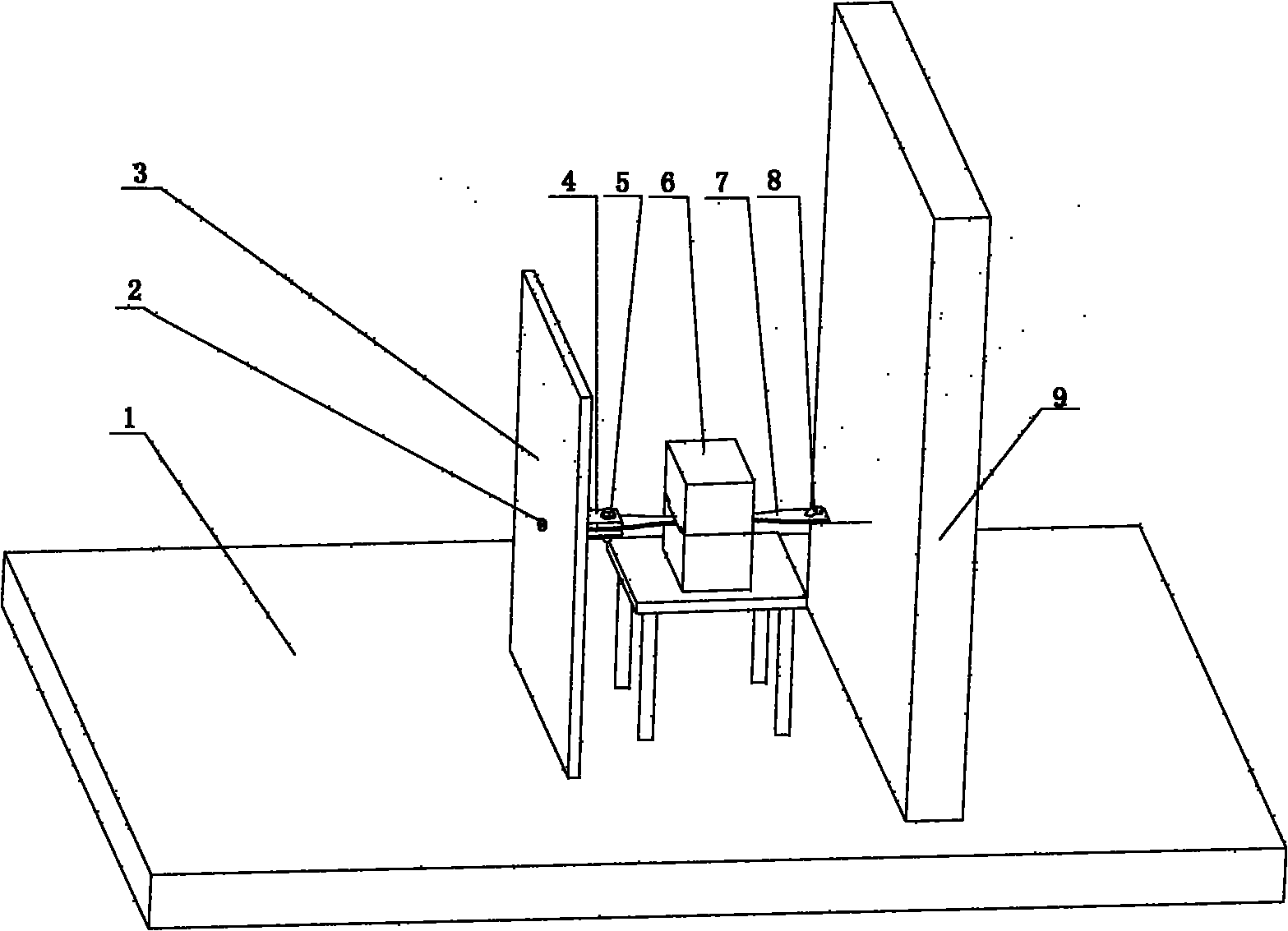

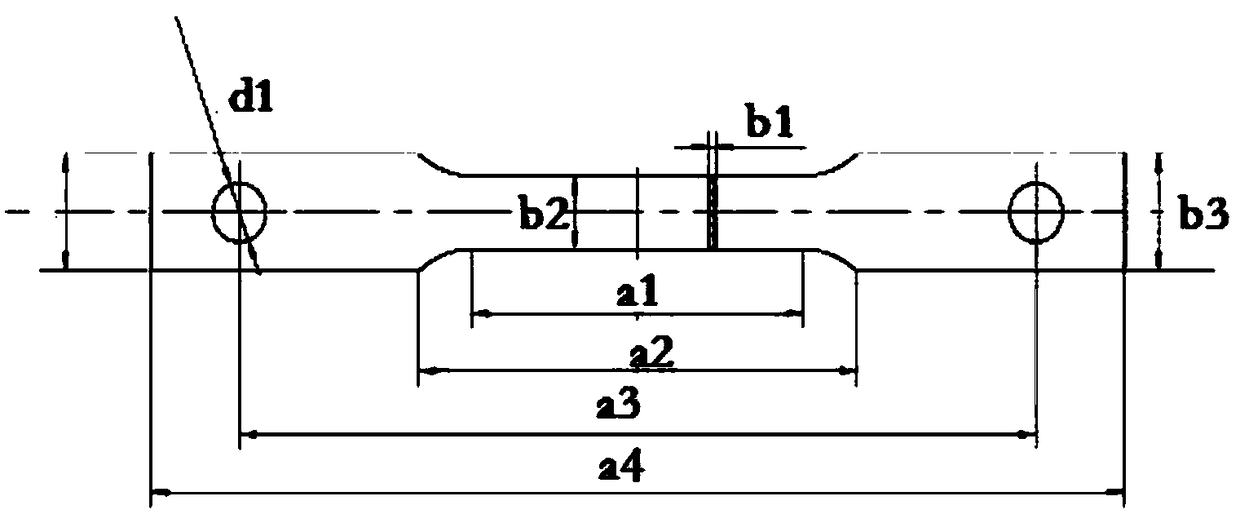

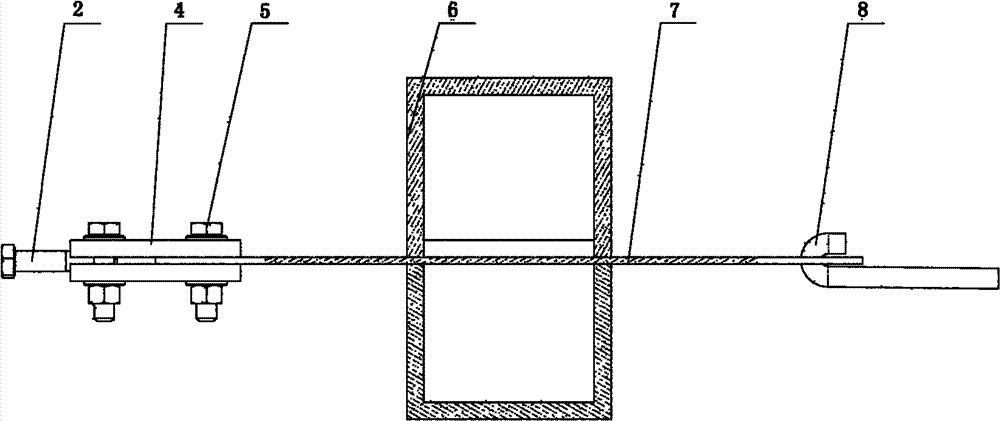

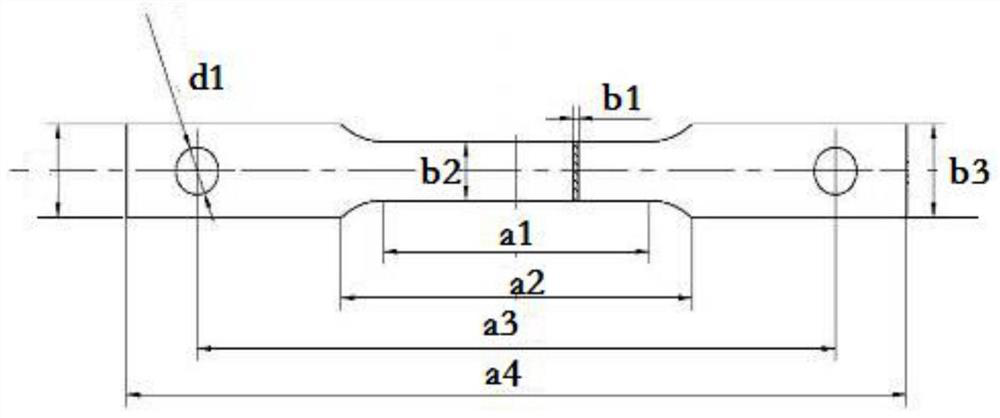

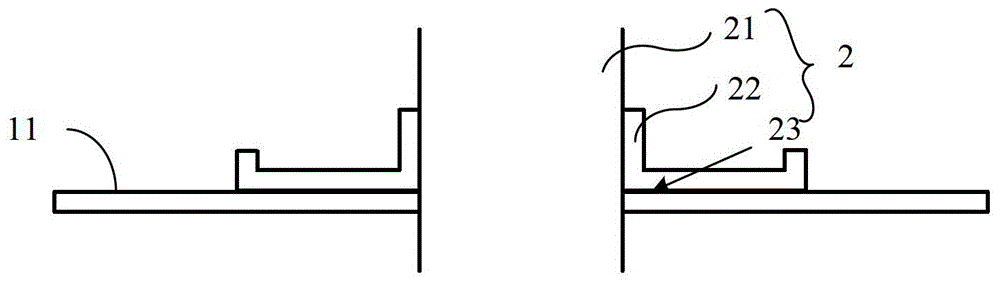

Stress corrosion test method and device for metal sheet pre-cracked sample

InactiveCN102103063ALower requirementSave materialWeather/light/corrosion resistanceCrazingMetallic materials

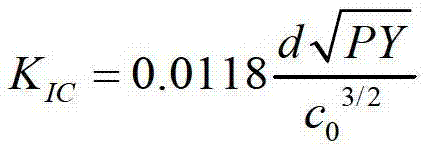

The invention discloses a stress corrosion test method and a stress corrosion test device for a metal sheet pre-cracked sample. The method comprises the following steps of: fixing one end of the sample on a bearing wall, clamping the other end of the sample by using an upper clamping plate and a lower clamping plate and fixing; clamping a test section of the sample by using a corrosion environment test box; pre-estimating the initially applied stress field intensity factor according to the threshold stress field intensity factor of crack propagation of similar metal materials, wherein the pre-estimated value is greater than the threshold stress field intensity factor of the crack propagation of the metal materials; loading stress to the metal sheet sample, measuring the crack length of the sheet sample to obtain a crack stress field intensity factor, and stopping loading the stress when the crack stress field intensity factor is equal to the pre-estimated value; filling a corrosion medium in the corrosion environment test box; measuring the length of a crack at the tip of the pre-cracked sample at intervals of certain time; and measuring the crack length and the loaded stress after the crack stress field intensity factor is stabilized to obtain the threshold stress field intensity factor of stress corrosion crack propagation. The method is convenient to operate and high in measuring accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

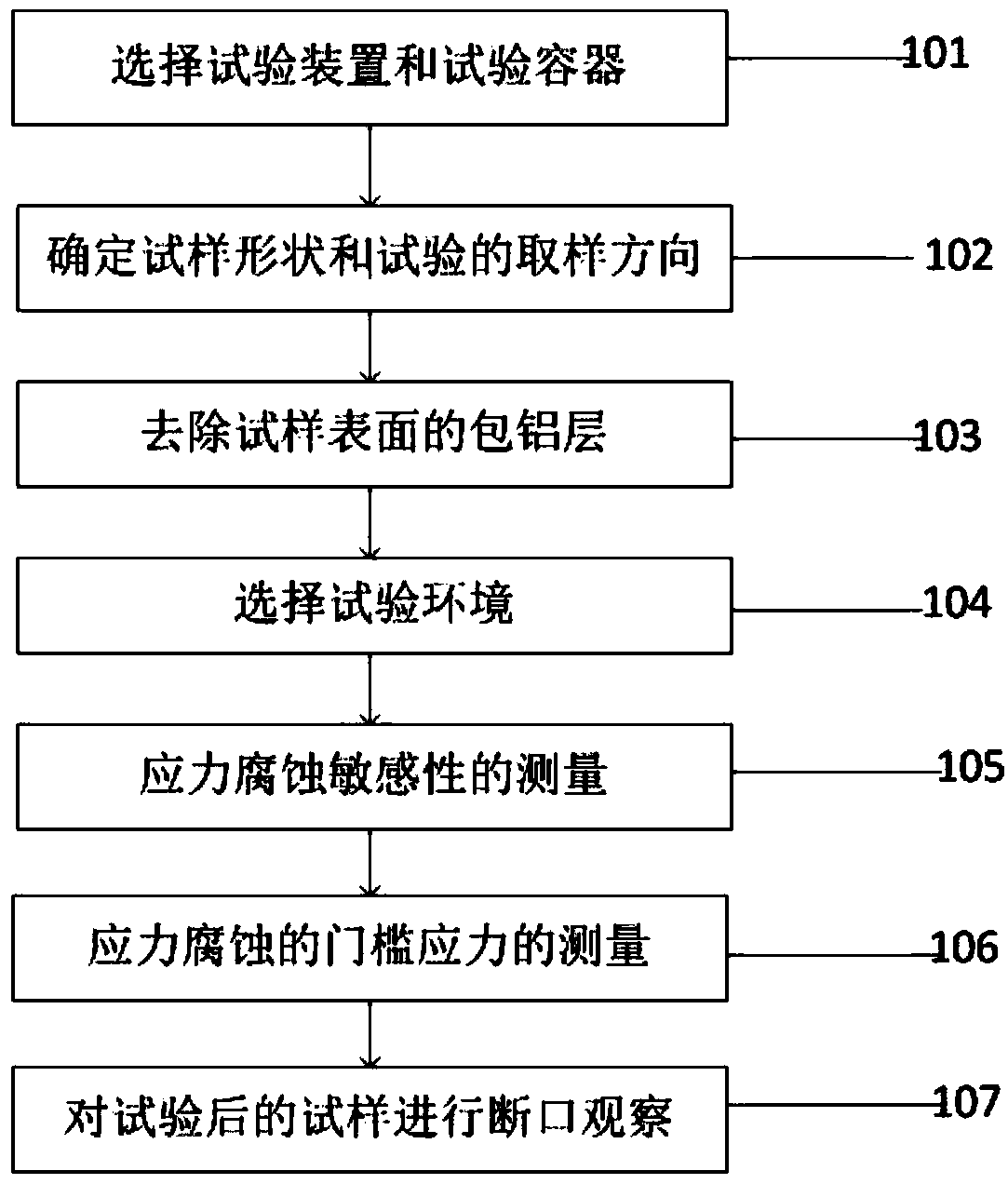

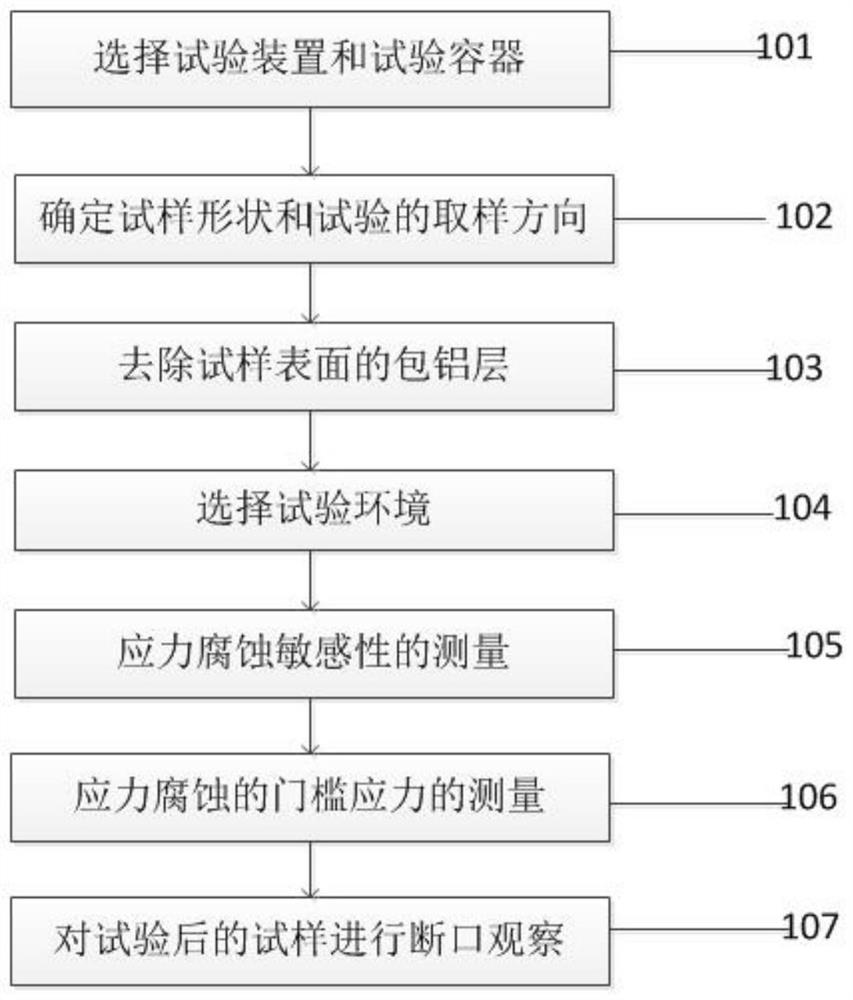

Method for measuring stretching stress corrosion of deforming aluminium alloy

ActiveCN108398320ASolve the inability to quantitatively measure the stress corrosion susceptibility of aluminum alloysReasonable testWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesAlclad5005 aluminium alloy

The invention discloses a method for measuring stretching stress corrosion of a deforming aluminium alloy. The method comprises the following steps: removing an alclad layer on the surface of a sample; measuring stress corrosion sensitivity through relative change of same mechanics parameters of the same sample exposed under contrast test environment and exposed under inertia environment; and measuring the threshold stress of stress corrosion according to a binary search method. The method for measuring the stretching stress corrosion of the deforming aluminium alloy is capable of performing quantification measurement on stress corrosion sensitivity of the aluminium alloy.

Owner:CASIC DEFENSE TECH RES & TEST CENT

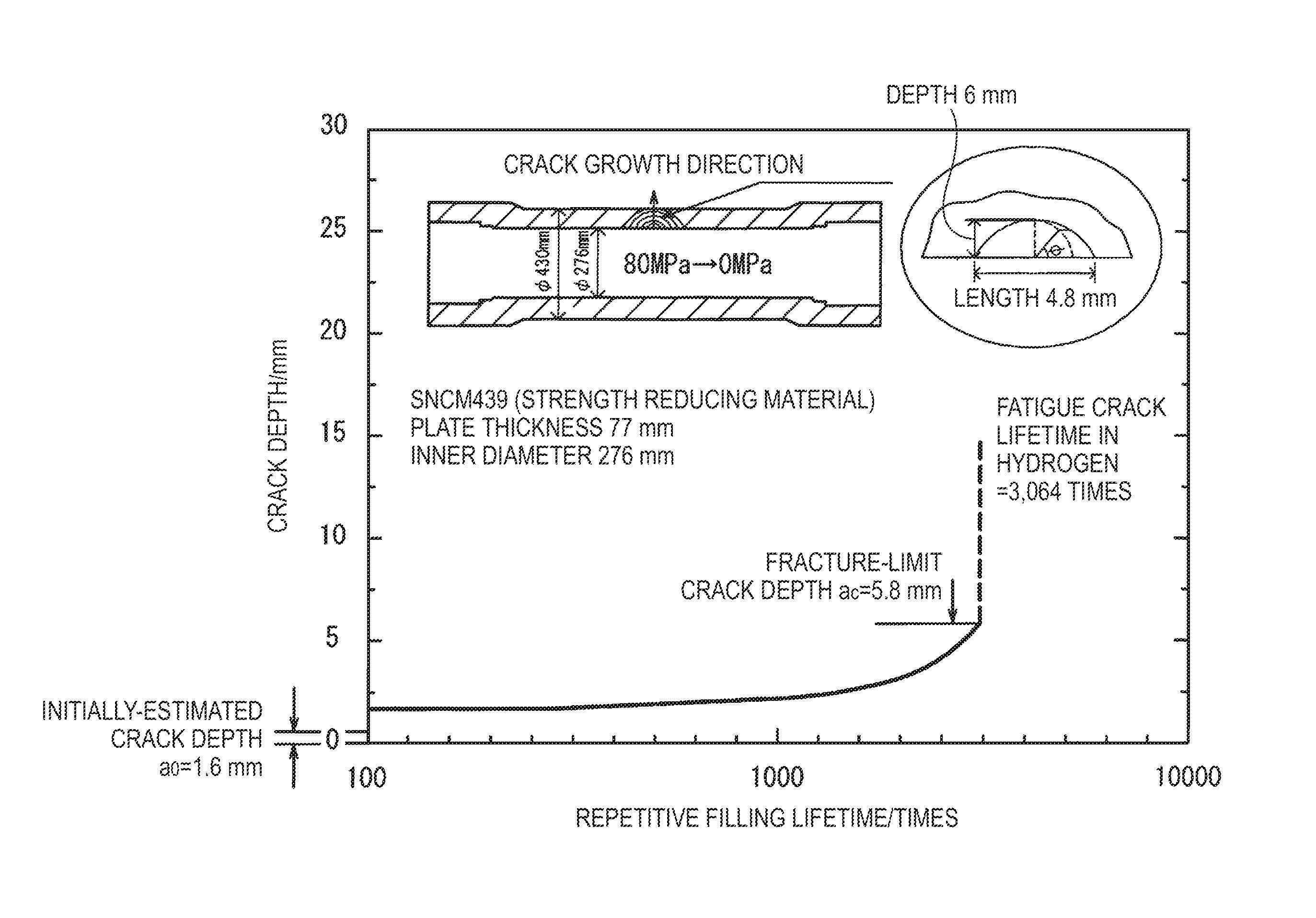

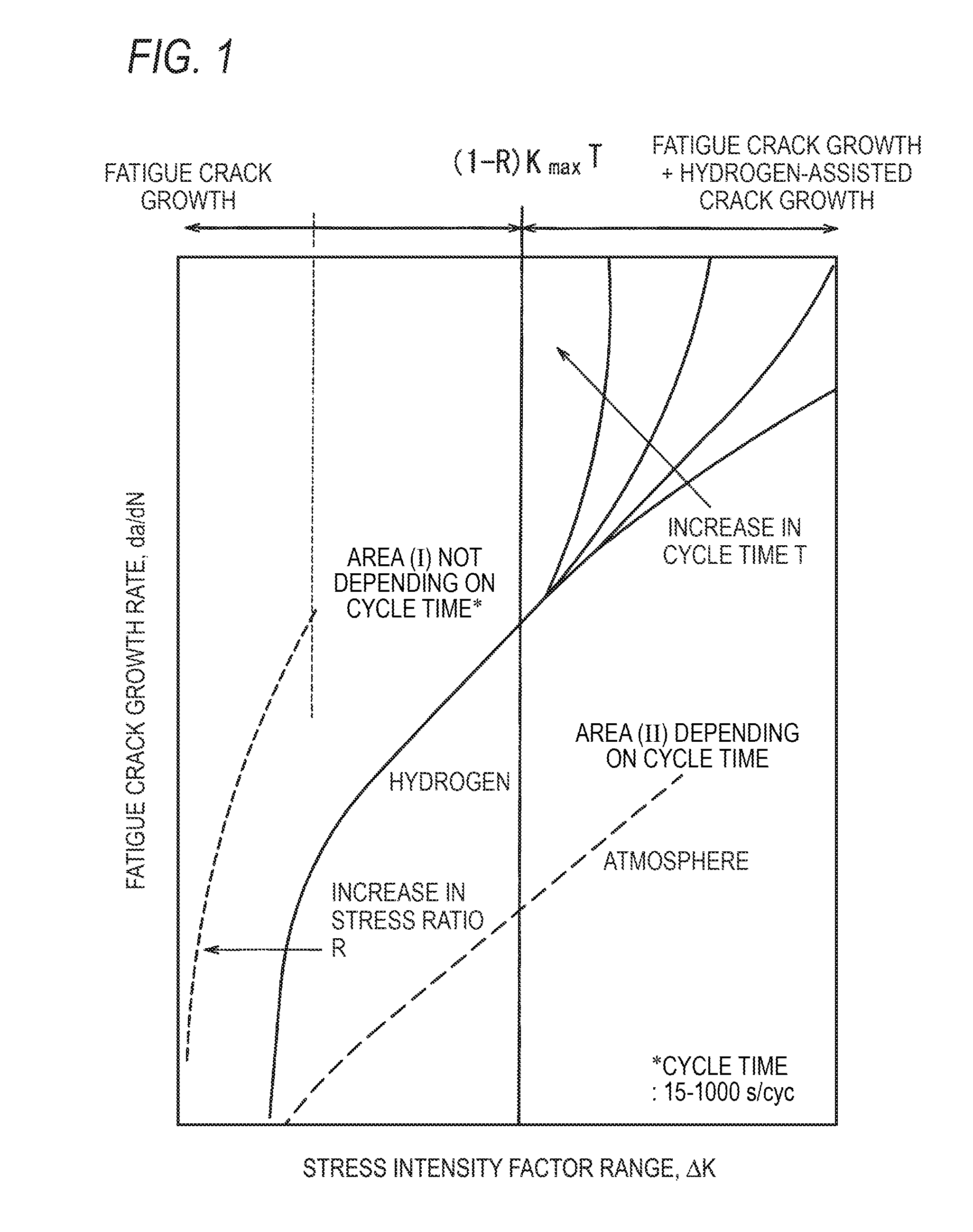

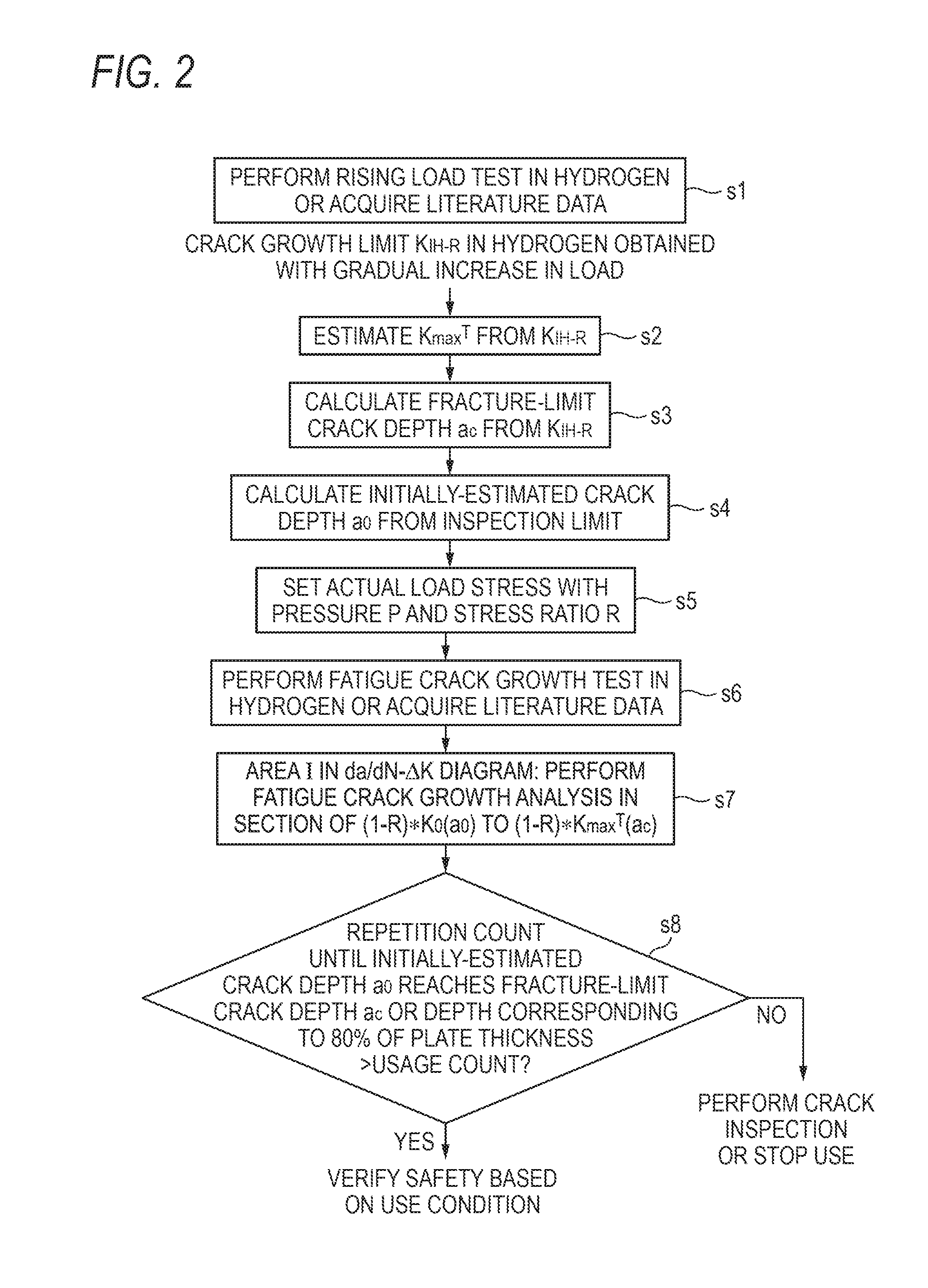

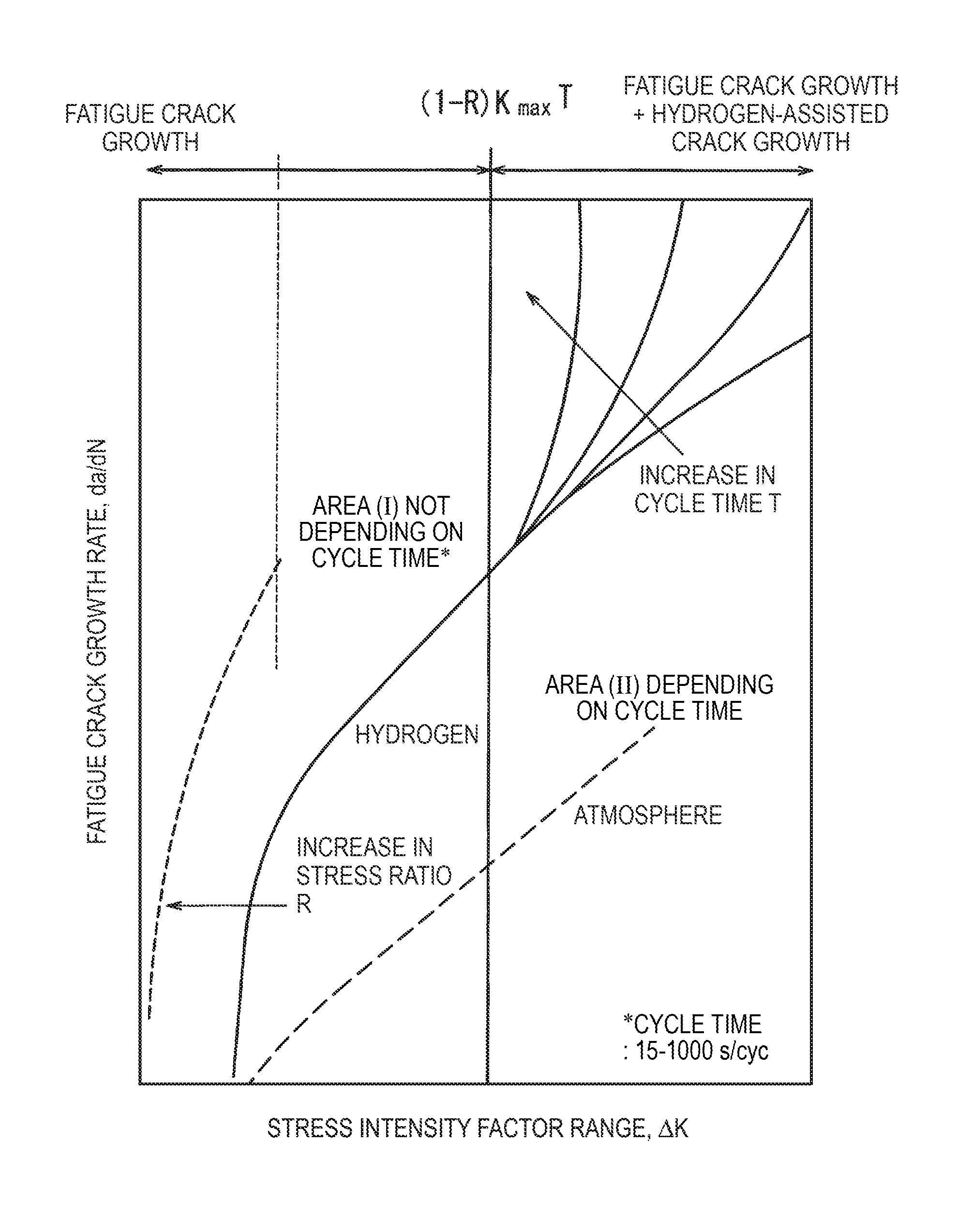

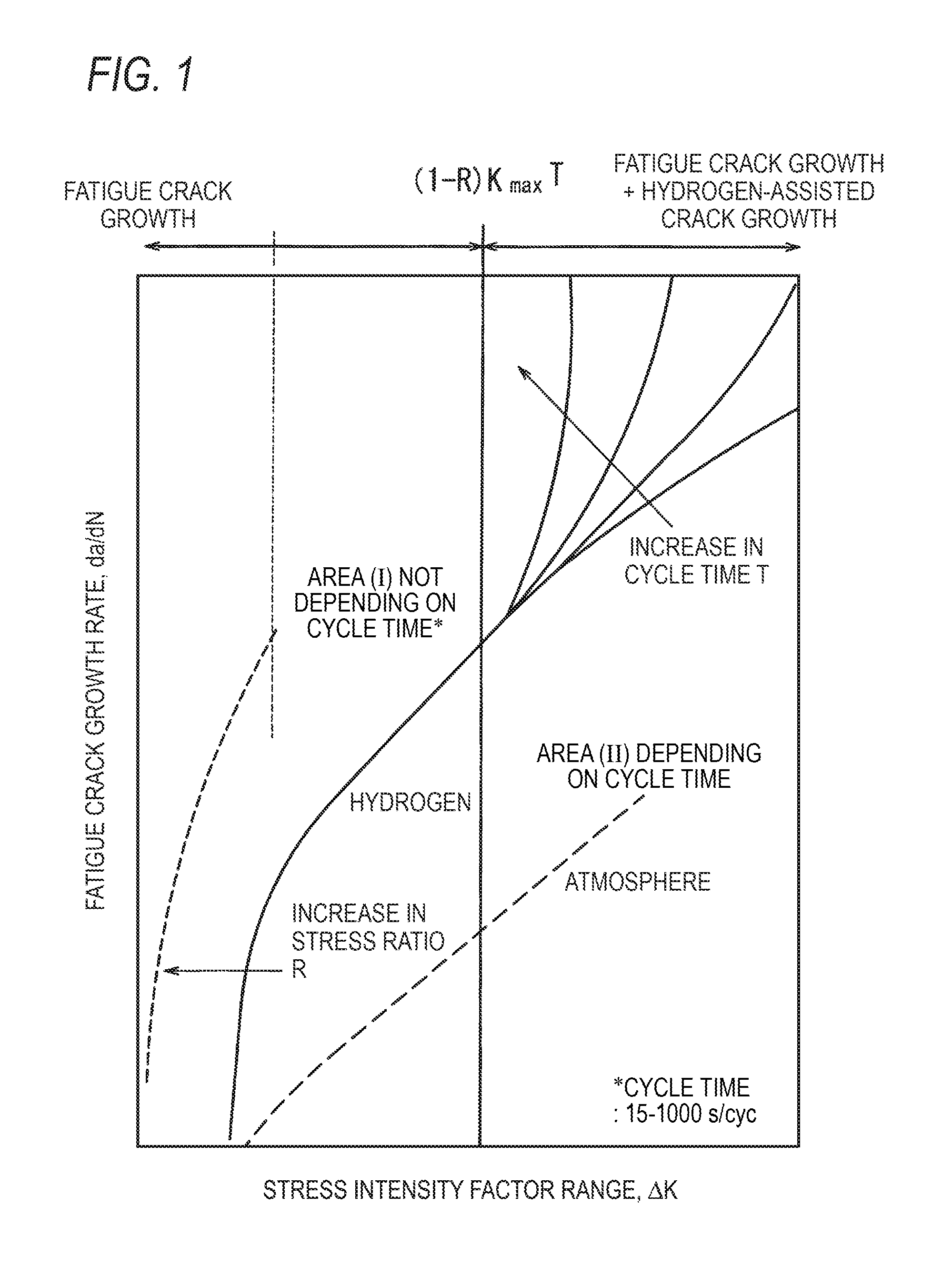

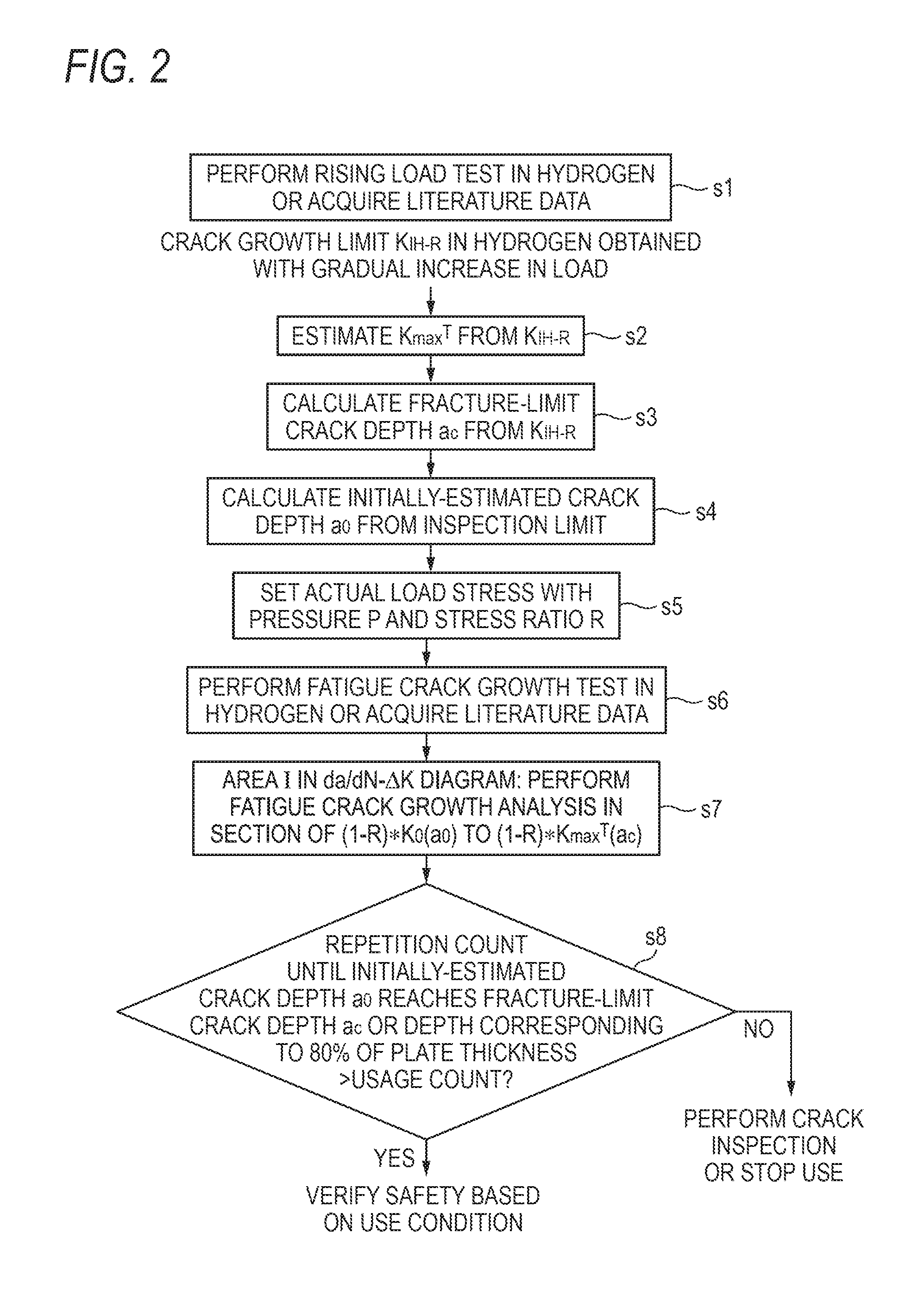

Method of determining fatigue crack lifetime in high-pressure hydrogen environment

ActiveUS20130333481A1Shorten the timeImprove assessment accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceHigh pressure hydrogenThreshold stress

In a method of determining a fatigue crack lifetime of a low-alloy steel material coming in contact with high-pressure hydrogen in a high-pressure hydrogen environment, estimate a fatigue crack acceleration starting point KmaxT of the low-alloy steel material using a crack-growth threshold stress intensity factor KIH-R obtained through a rising load test on the low-alloy steel material in a high-pressure hydrogen environment. The high-pressure hydrogen environment of the rising load test is a high-pressure hydrogen environment which has the same pressure and atmosphere as in the high-pressure hydrogen environment in which KmaxT is estimated and in which the test temperature tolerance between both environments is ±5° C.

Owner:JAPAN STEEL WORKS LTD

Method of determining fatigue crack lifetime in high-pressure hydrogen environment

InactiveUS9151706B2Improve researchLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceHigh pressure hydrogenMetallurgy

In a method of determining a fatigue crack lifetime of a low-alloy steel material coming in contact with high-pressure hydrogen in a high-pressure hydrogen environment, estimate a fatigue crack acceleration starting point KmaxT of the low-alloy steel material using a crack-growth threshold stress intensity factor KIH-R obtained through a rising load test on the low-alloy steel material in a high-pressure hydrogen environment. The high-pressure hydrogen environment of the rising load test is a high-pressure hydrogen environment which has the same pressure and atmosphere as in the high-pressure hydrogen environment in which KmaxT is estimated and in which the test temperature tolerance between both environments is ±5° C.

Owner:JAPAN STEEL WORKS LTD

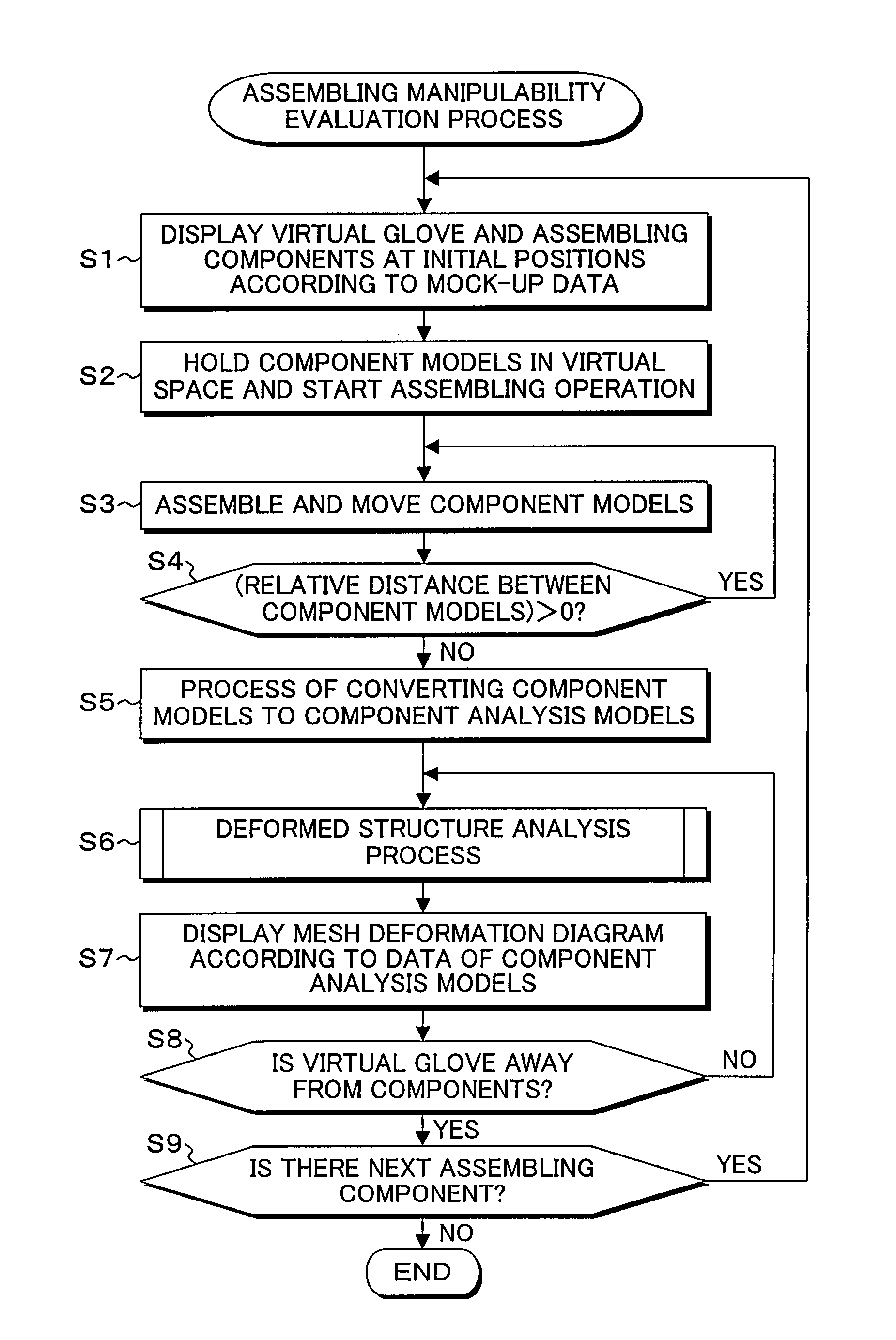

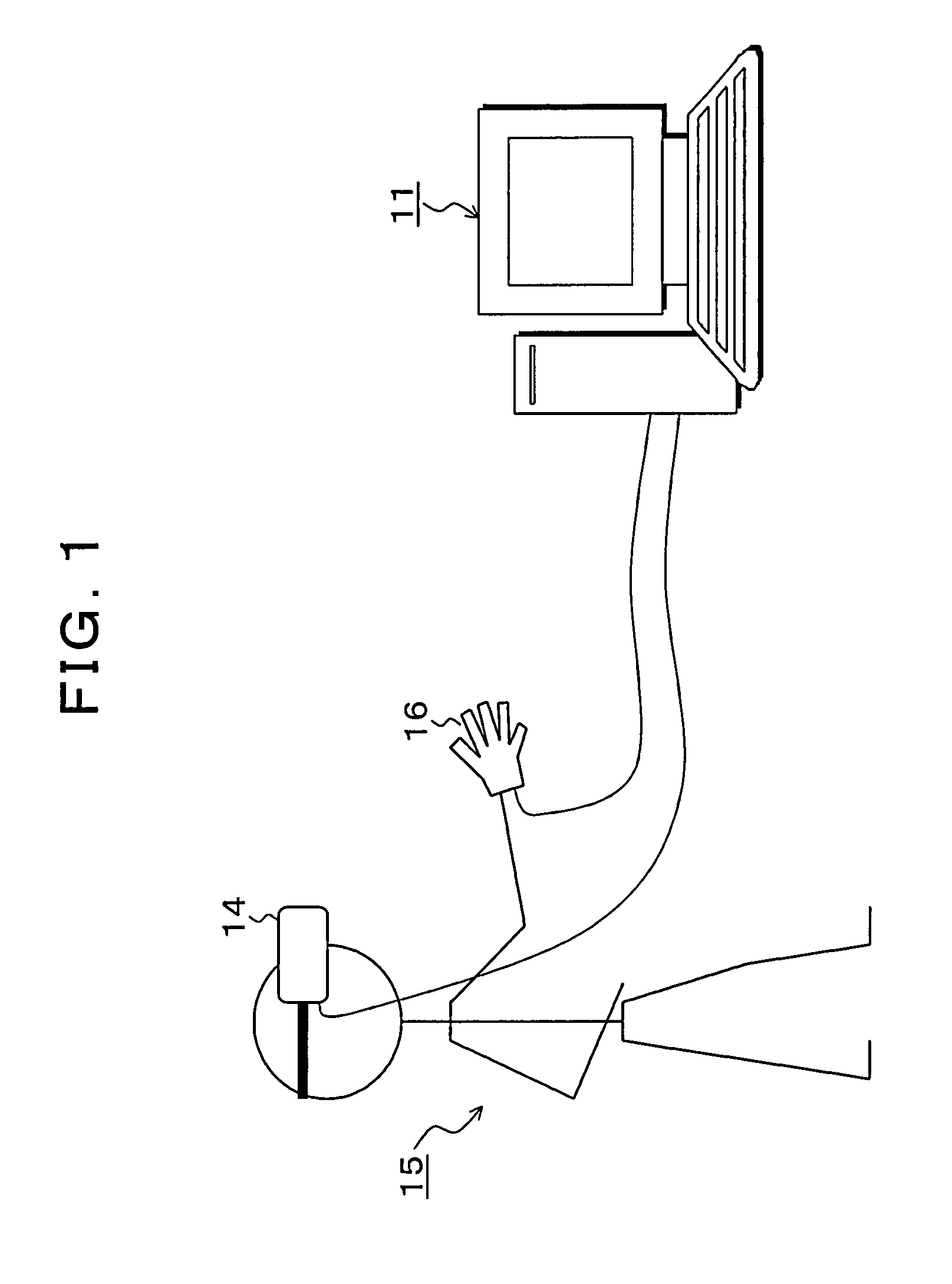

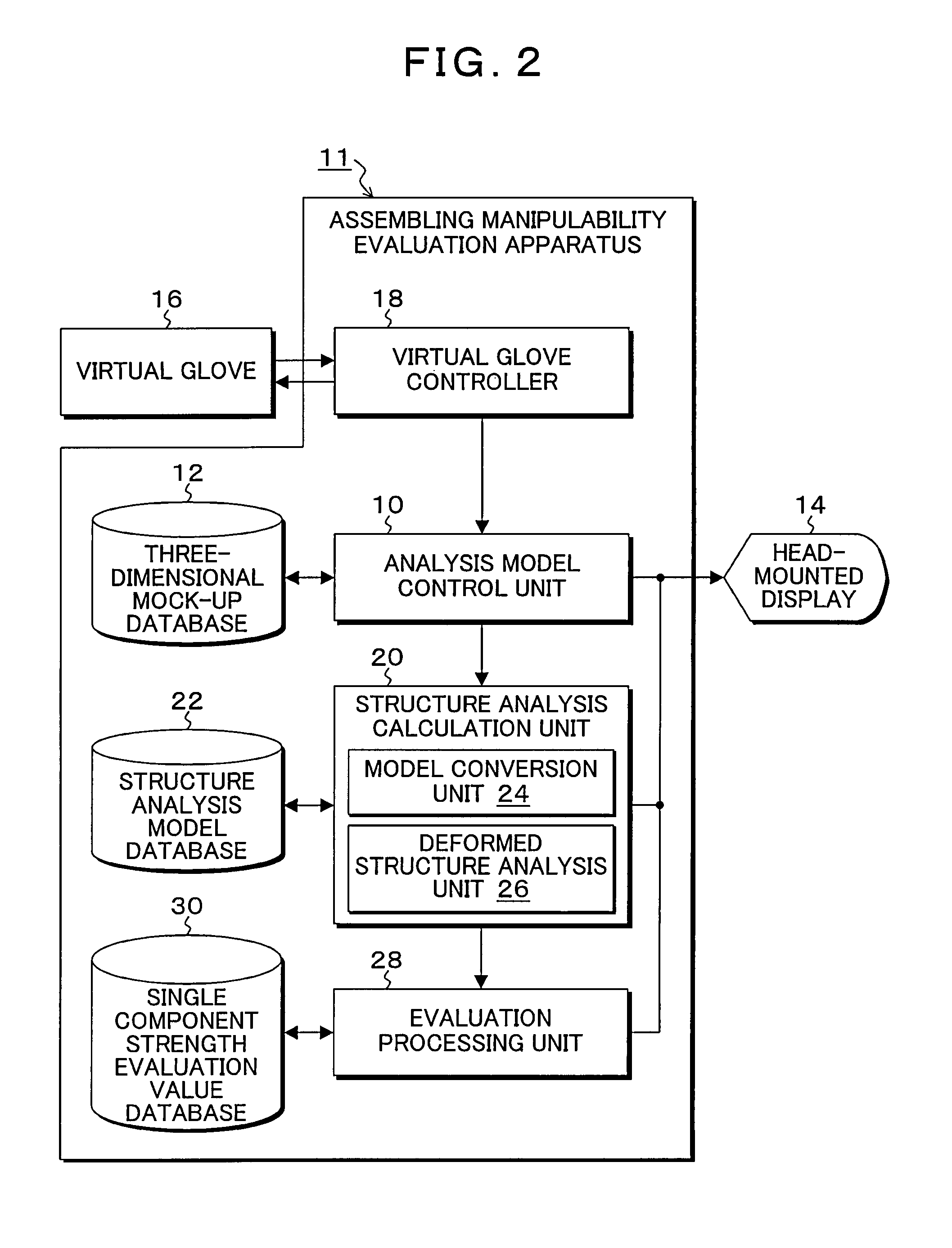

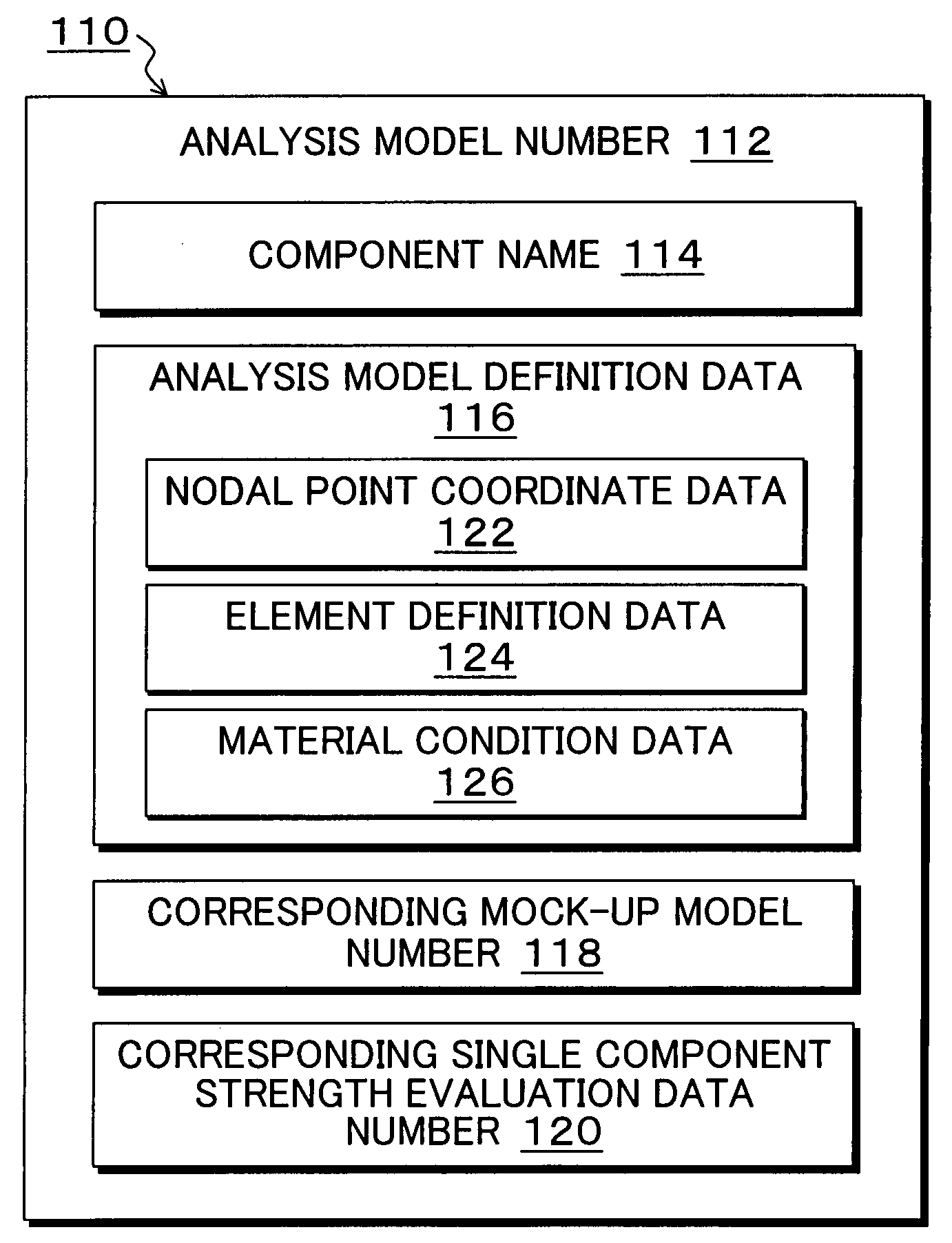

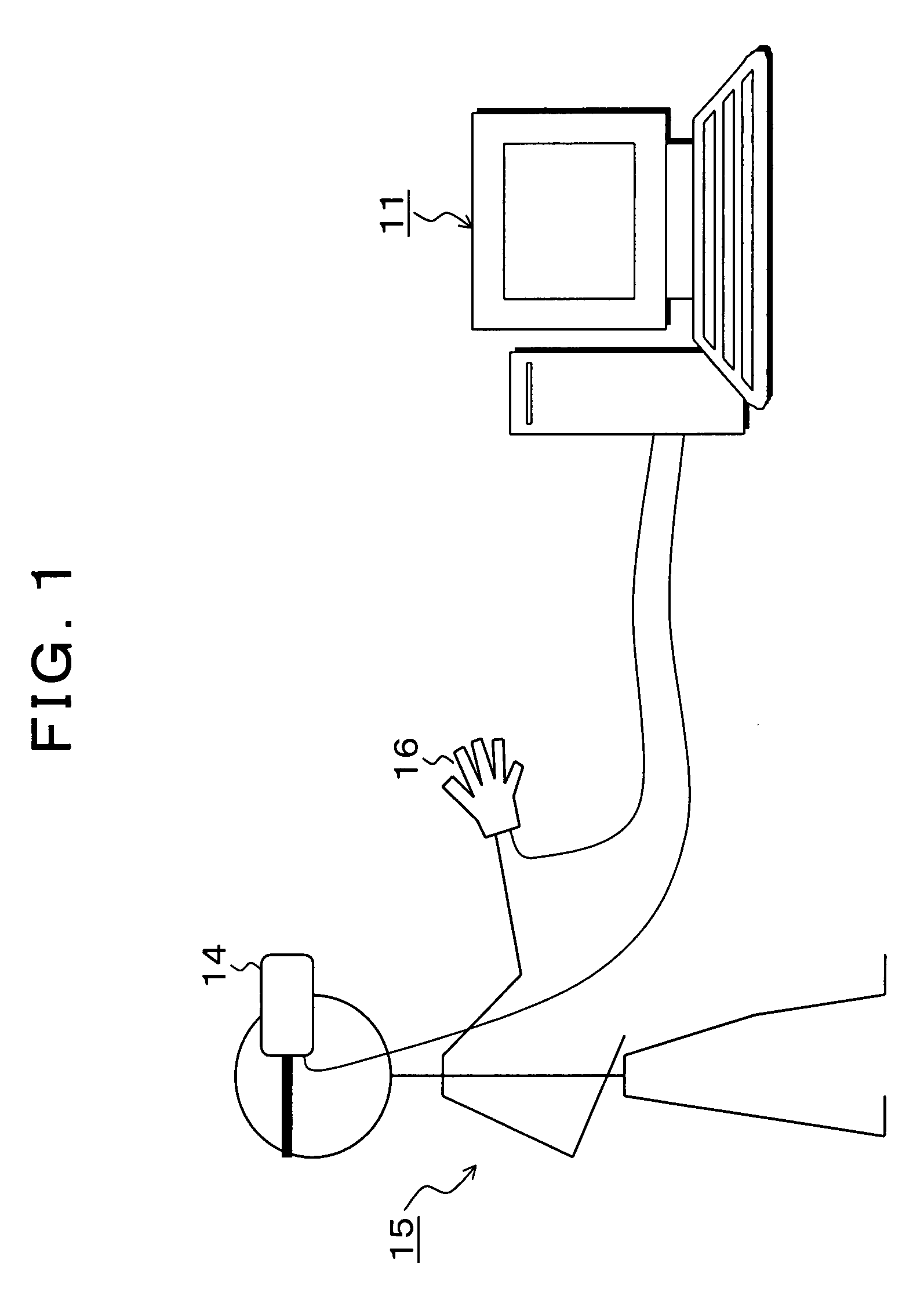

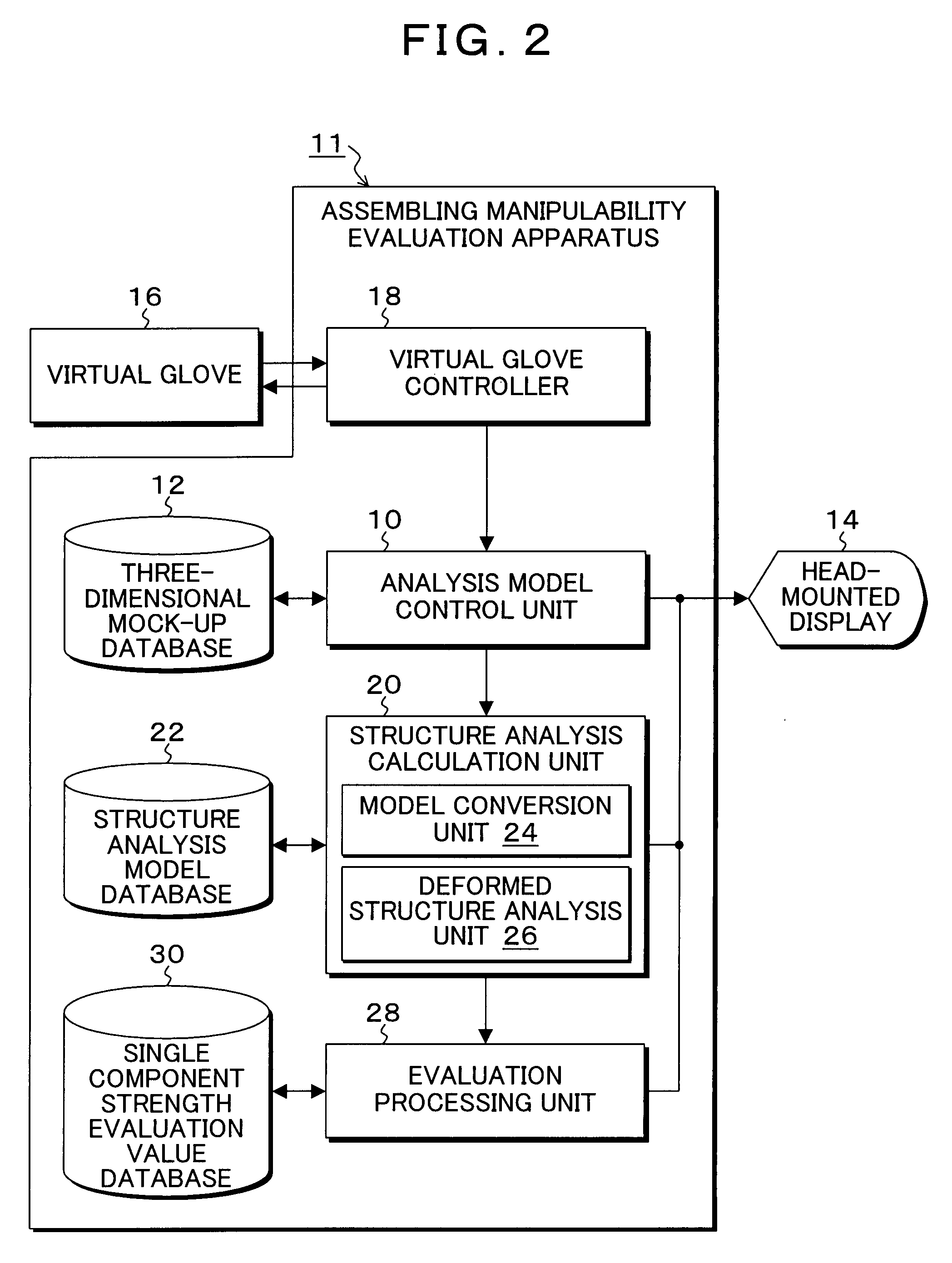

Assembling manipulability evaluation apparatus, method, and program

ActiveUS8447572B2Design optimisation/simulationSpecial data processing applicationsStructure analysisUser input

An analysis model control unit disposes at least two component models, which are to be used in assembly of a product to be evaluated, in virtual space displayed on a screen. A virtual glove controller moves and operates component models, which are disposed in virtual space, in accordance with an input operation signal of a user by a virtual glove. When the two component models are brought into contact with each other, a model conversion unit converts them into component analysis models. A deformed structure analysis unit executes structure analysis calculations with respect to the relative movement caused along with assembly of the two component analysis models after contact so as to calculate deformation and deformation stresses. An evaluation processing unit compares the deformation stress with a threshold stress of the material so as to evaluate whether assembly can be performed without breaking the components.

Owner:FUJITSU LTD

Assembling manipulability evaluation apparatus, method, and program

ActiveUS20080162097A1Design optimisation/simulationSpecial data processing applicationsStructure analysisUser input

An analysis model control unit disposes at least two component models, which are to be used in assembly of a product to be evaluated, in virtual space displayed in a screen. A virtual glove controller which functions as a virtual operation control unit moves and operates component models, which are disposed in virtual space, in accordance with an input operation signal of a user by a virtual glove. When the two component models are brought into contact with each other, a model conversion unit converts them into component analysis models. A deformed structure analysis unit executes structure analysis calculations with respect to the relative movement caused along with assembly of the two component analysis models after contact so as to calculate deformation and deformation stresses. An evaluation processing unit compares the deformation stress obtained as a result of the structure analysis calculations of the component analysis models with a threshold stress of the material so as to evaluate whether assembly can be performed without breaking the components.

Owner:FUJITSU LTD

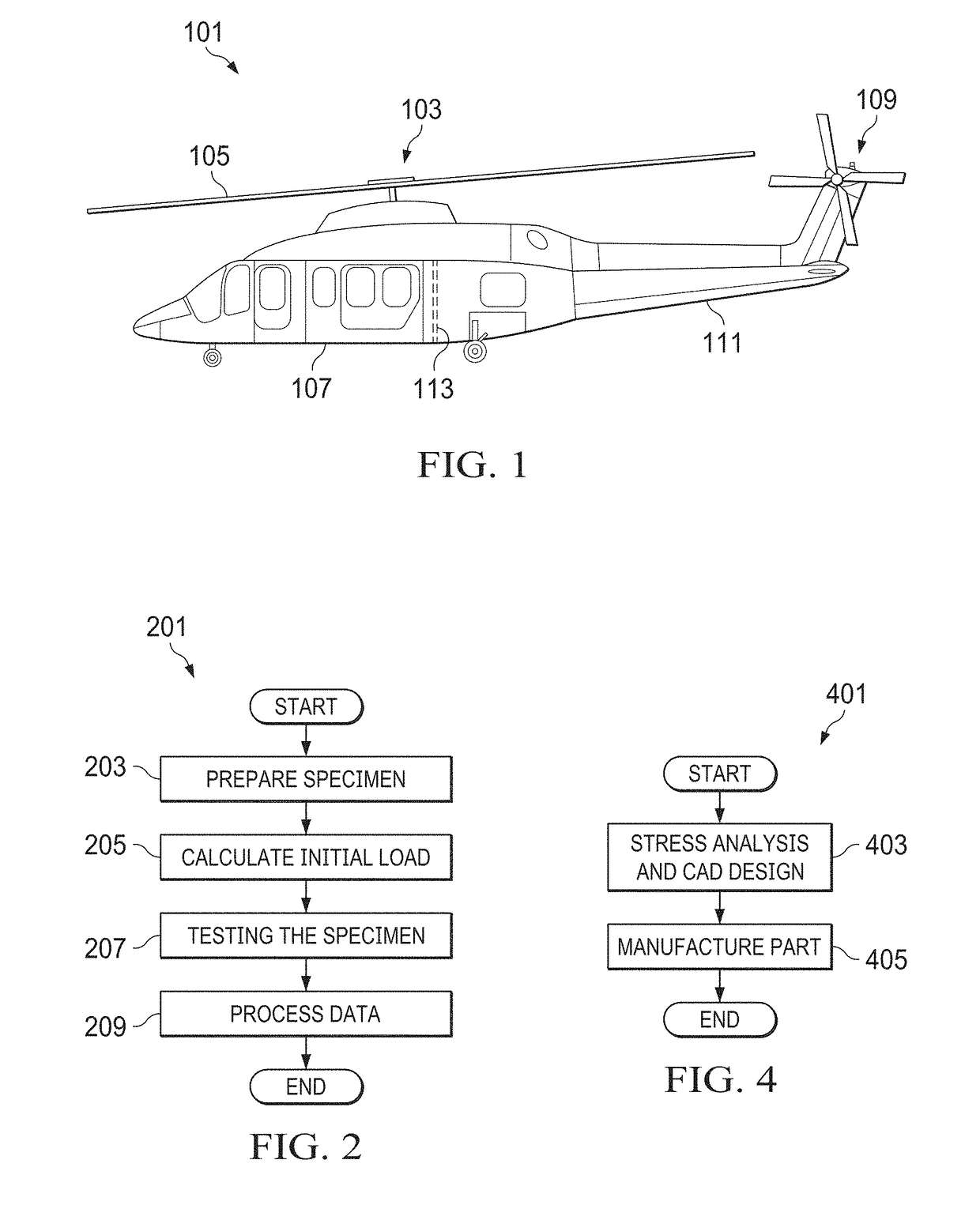

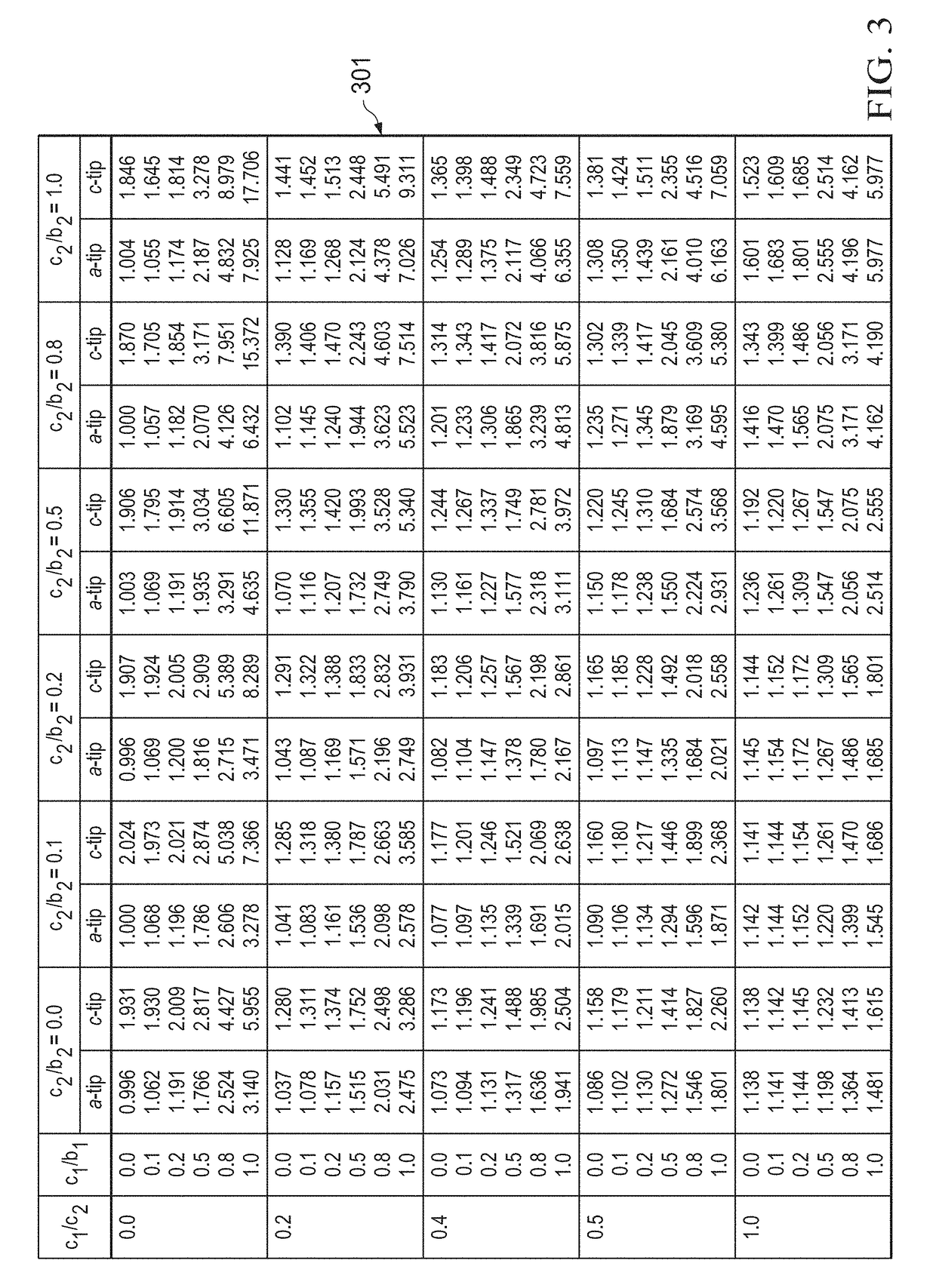

Method for defining threshold stress curves utilized in fatigue and damage tolerance analysis

A method for defining a threshold stress curve utilized in fatigue and / or damage tolerance analysis, the method including conducting a direct test method on a plurality of specimens with a notch to generate raw data, the notch in each of the specimens having a notch dimension; determining a plurality of analyzed data points based upon the raw data; determining a regression line based upon the plurality of data points, the regression line including an exponential portion and a power law portion; and connecting the exponential portion and the power law portion of the regression line to form a threshold stress curve based on the regression line.

Owner:BELL HELICOPTER TEXTRON INC

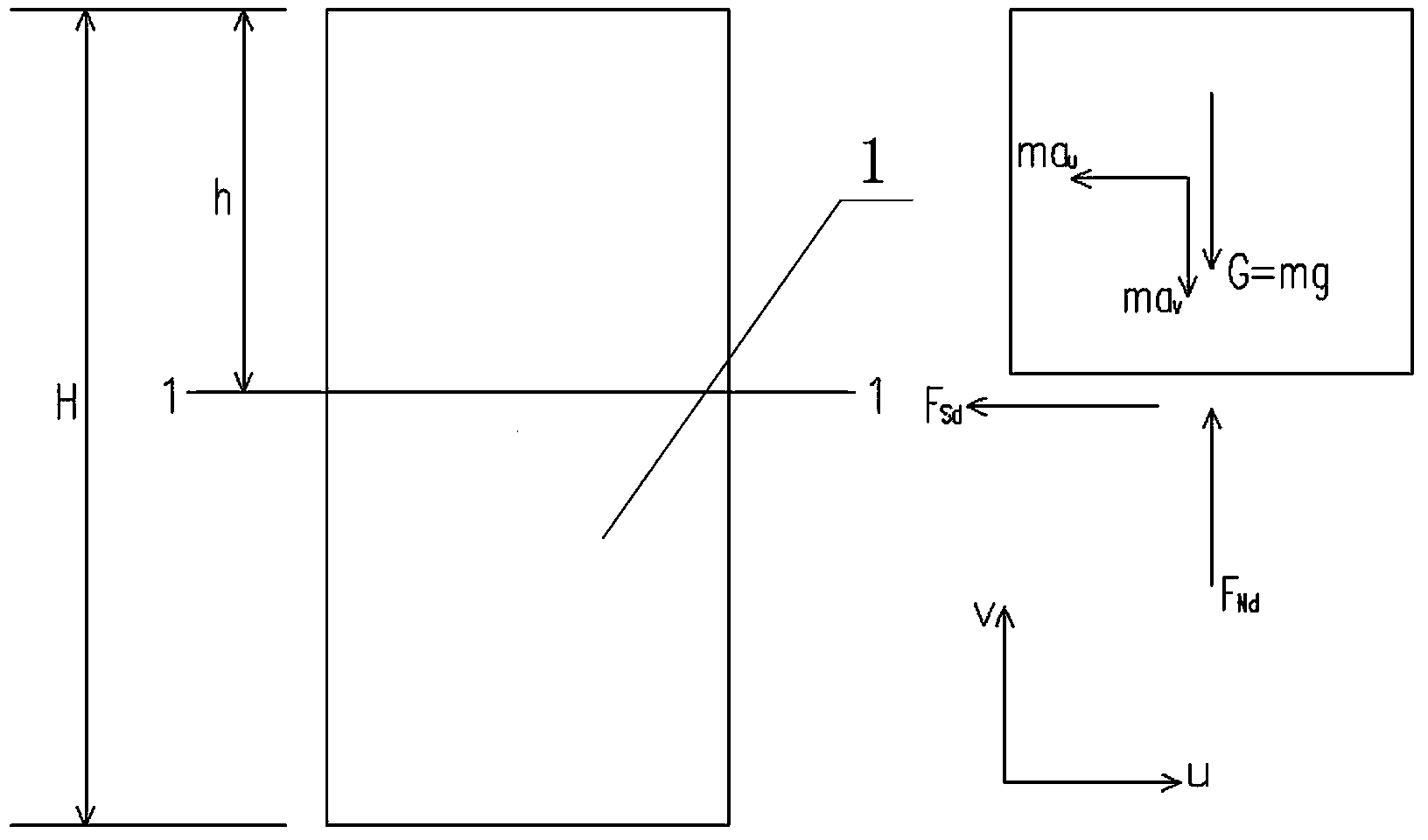

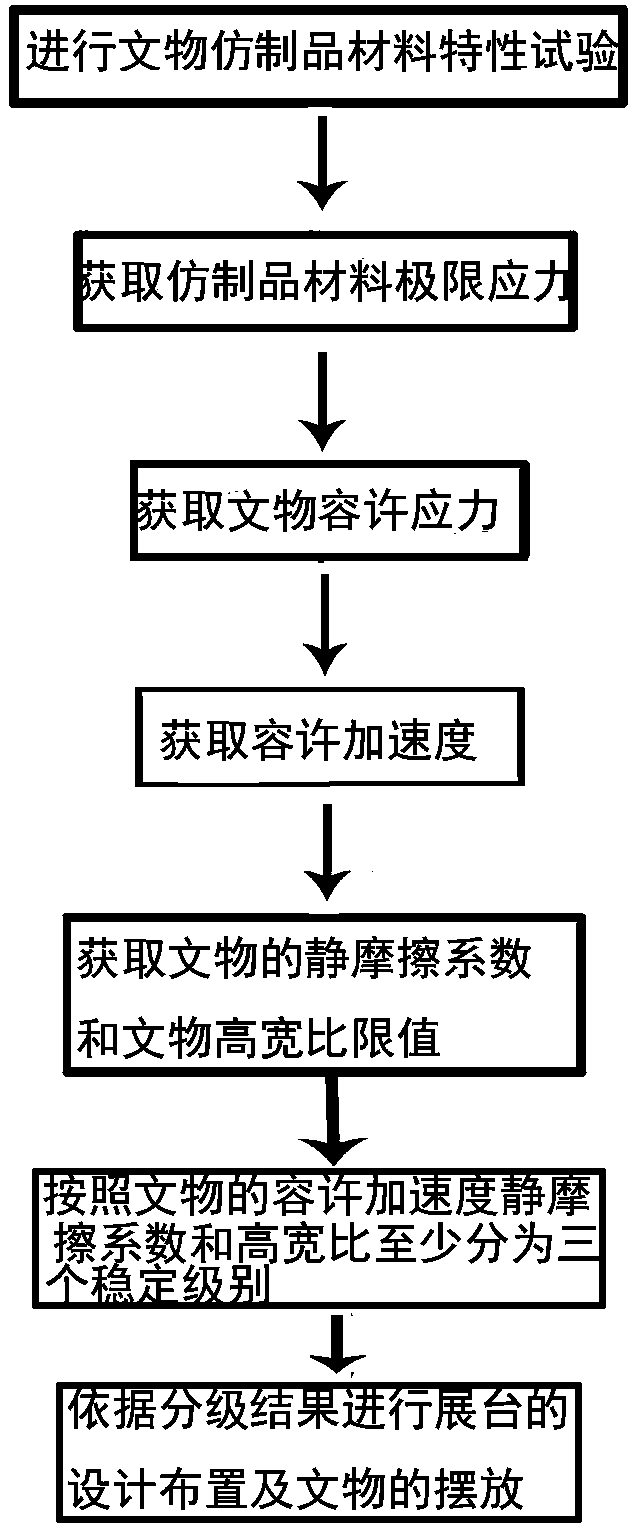

Method for protecting safety and stability of movable museum collection in earthquake

InactiveCN103810385AImprove securityThe method of discrimination is simpleSpecial data processing applicationsDynamic modulus of elasticityEngineering

The invention relates to a method for protecting the safety and stability of a movable museum collection in an earthquake. The method comprises the following steps: a museum collection imitation is subjected to a material characteristic test in a laboratory, so that tensile and compression resistance limit stress, shear resistance limit stress and a dynamic modulus of elasticity and a dynamic modulus of shearing of a material are obtained; after a stress reduction factor K is fetched, the tensile and compression resistance limit stress and the shear resistance limit stress of the imitation are multiplied by the K, and the product serves as allowable dynamic stress of the museum collection; allowable acceleration is calculated according to the D'Alembert's principle; the stability of the museum collection is classified into three stability levels according to the allowable acceleration, the friction factor and the height-width ratio (namely the allowable vibration index)of the museum collection; finally, an exhibition stand is designed and arranged, and the museum collection is placed according to a classification result. The discriminating method is simple and practicable, and the result is accurate; the allowable vibration index provides a scientific basis and a quantitative criterion for control cover the safety guarantee of the museum collection in an earthquake.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Method for Monitoring the Carrying Capacity of Steel-Concrete Structures

InactiveUS20090231151A1Reduce resistanceObserve clearlyResistance/reactance/impedenceAlarmsPre stressingEngineering

A method for monitoring and estimating the carrying capacity of a pre-stressed ferromagnetic metal armature element of a metal-concrete load-bearing structure is proposed, comprising the steps of: preliminary calibrating the element by passing electric current therethrough and measuring its electrical resistance with respect to the tension stress applied to the element, determination of an ultimate resistance value corresponding to a predetermined ultimate limit stress value permitted to the element, saving the ultimate resistance value in a computer memory, passing electric current through the element during construction or exploitation of the load-bearing structure being in a loaded state, measuring altered resistance of the element, comparing the altered resistance with the ultimate resistance value, and warning when the altered resistance reaching the ultimate resistance value. Additional embodiments disclose deployment of two types of electric current: alternating and direct. The method allows significantly increasing safety of metal-concrete structures and reducing electric energy consumption.

Owner:KOROLEV IGOR GENNADIEVICH

Gear Bending Fatigue Life Prediction Method and Device

ActiveCN106886663BSimplify the operating life prediction processPredicting Flexural Fatigue LifeGeometric CADDesign optimisation/simulationGear wheelClassical mechanics

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

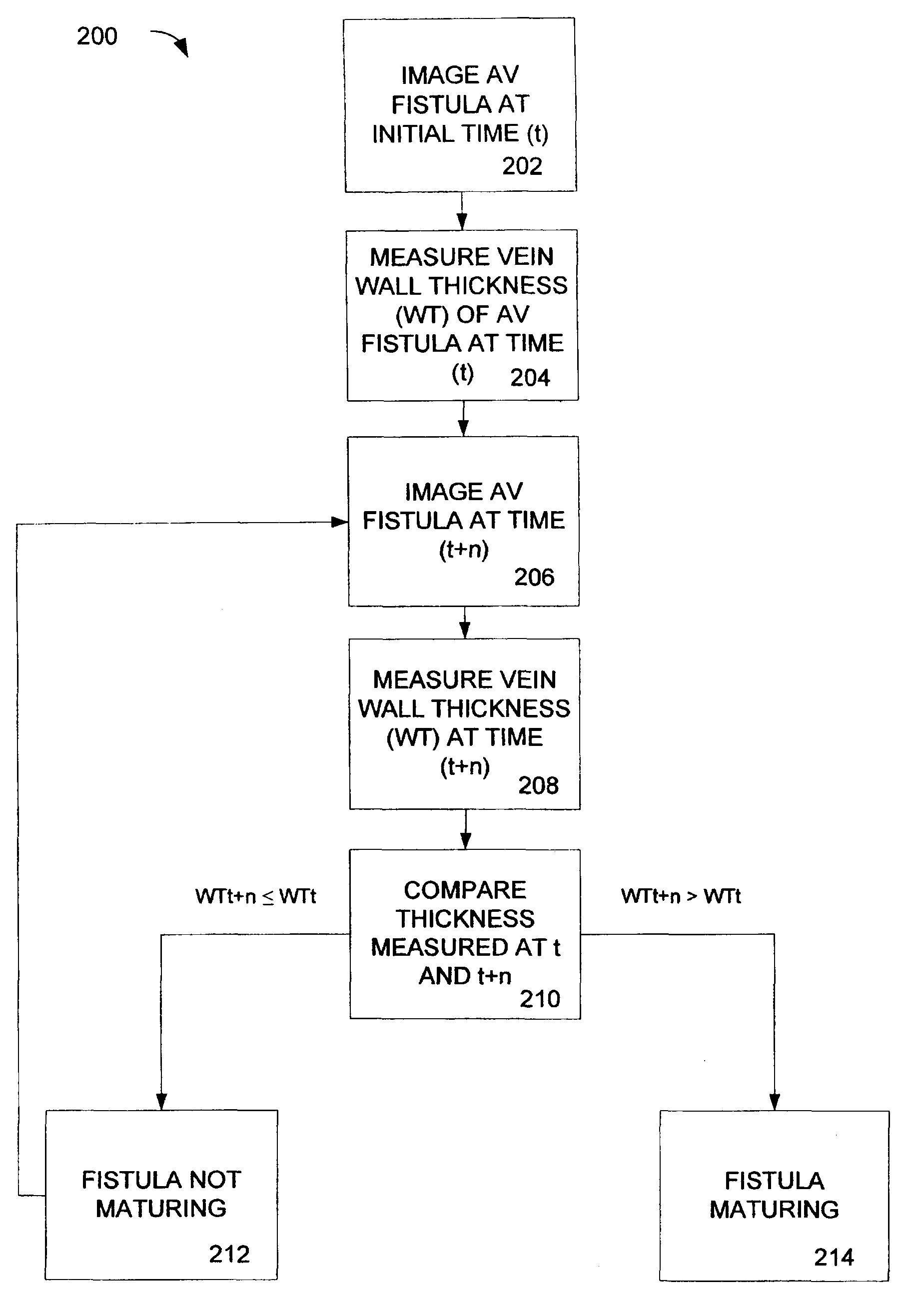

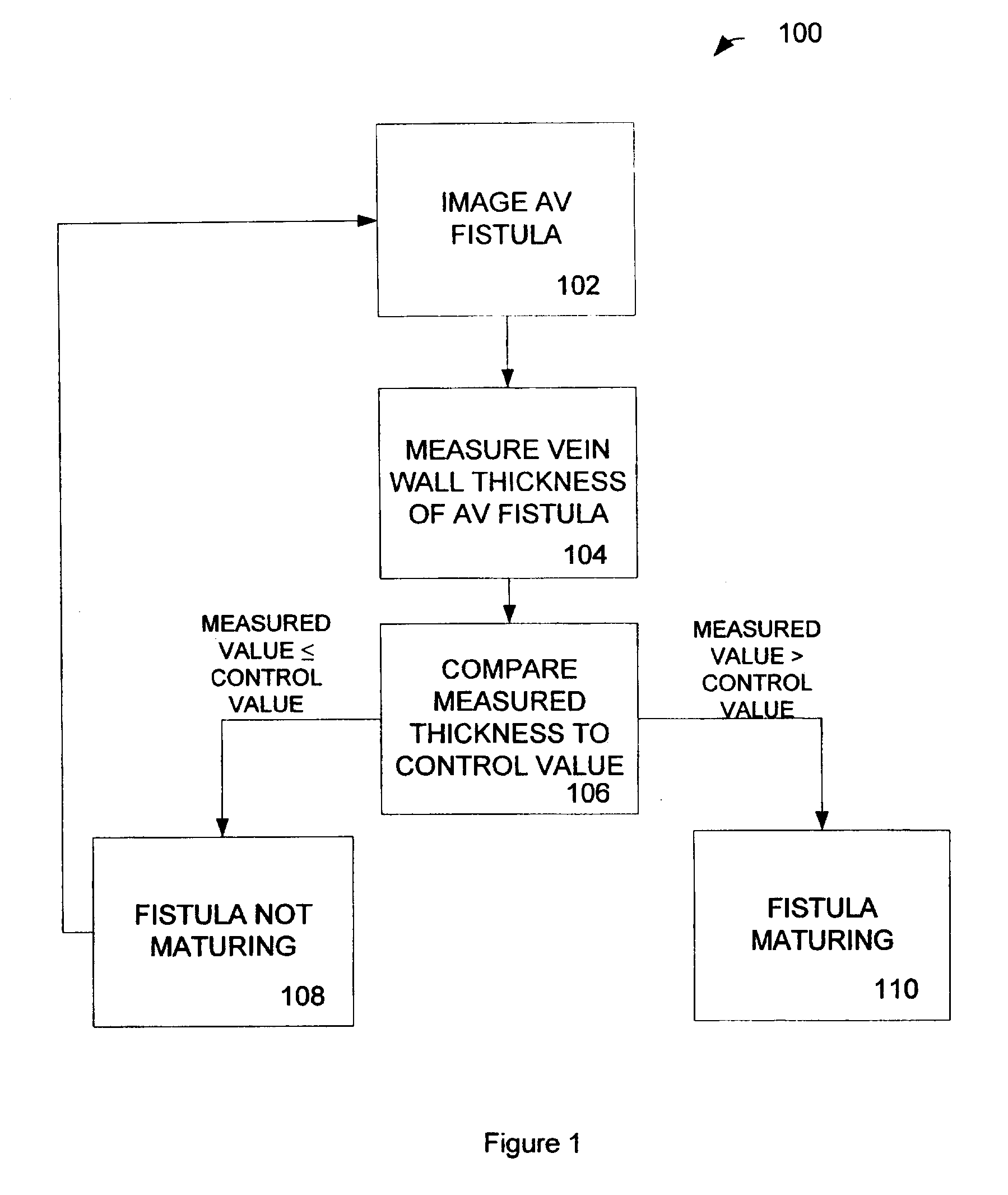

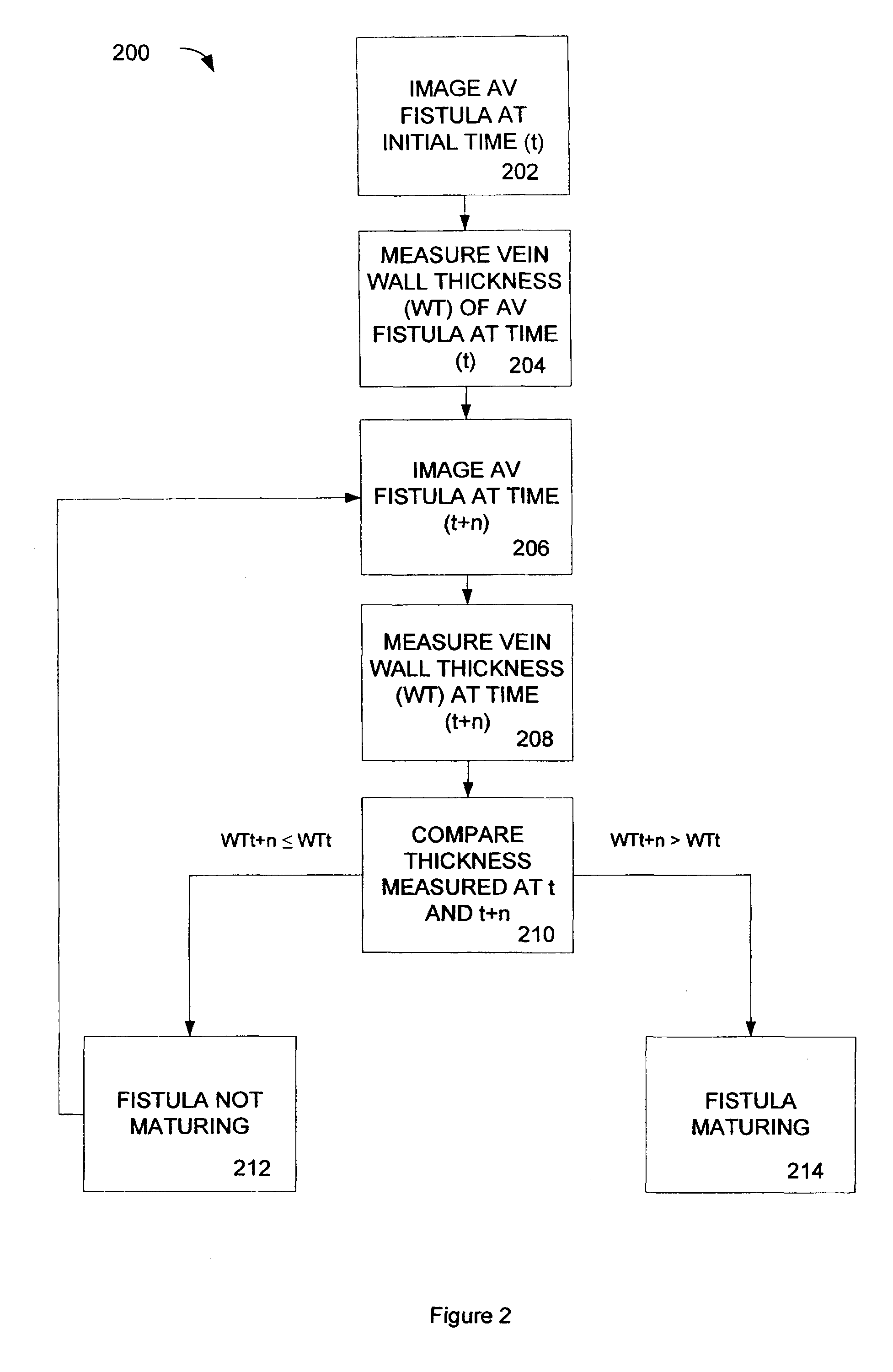

Ultrasonic evaluation of venous structures

Provided are methods and systems for detecting a maturing arterio-venous fistula comprising a vein. An exemplary method comprises determining a wall thickness of the fistula and a lumen diameter of the fistula vein using a high frequency ultrasound imaging system. A blood pressure of the subject is determined. A circumferential vessel wall stress is determined from the measured blood pressure, the wall thickness of the fistula and a determined radius of the measured diameter of the fistula. The determined circumferential vessel stress is compared to a predetermined threshold stress to determine if the fistula is mature.

Owner:ST MICHAELS HOSPITAL

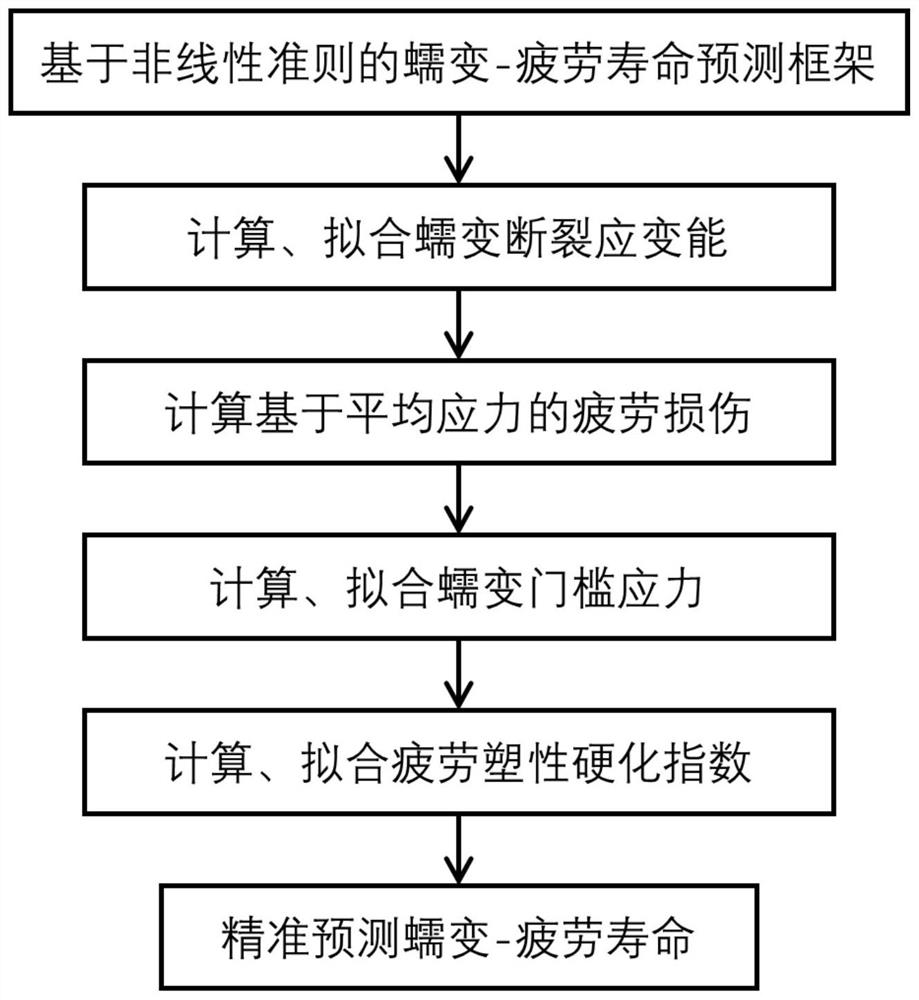

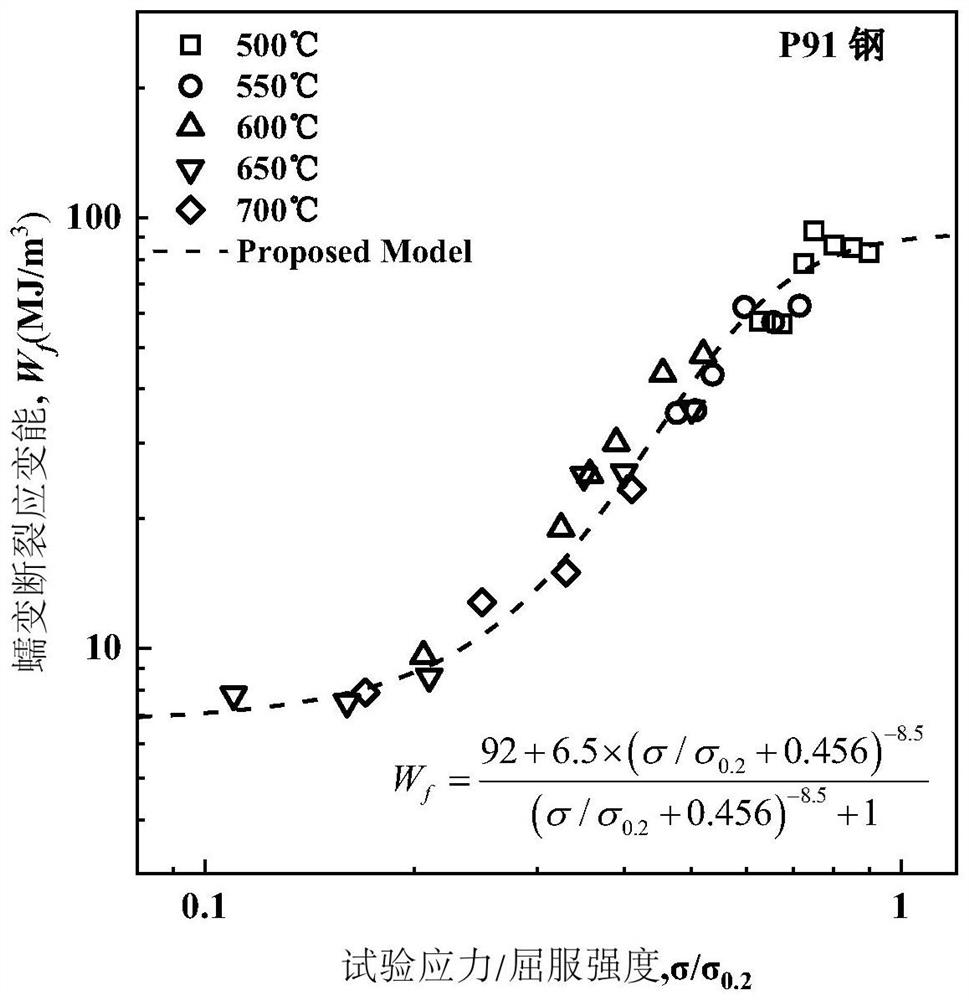

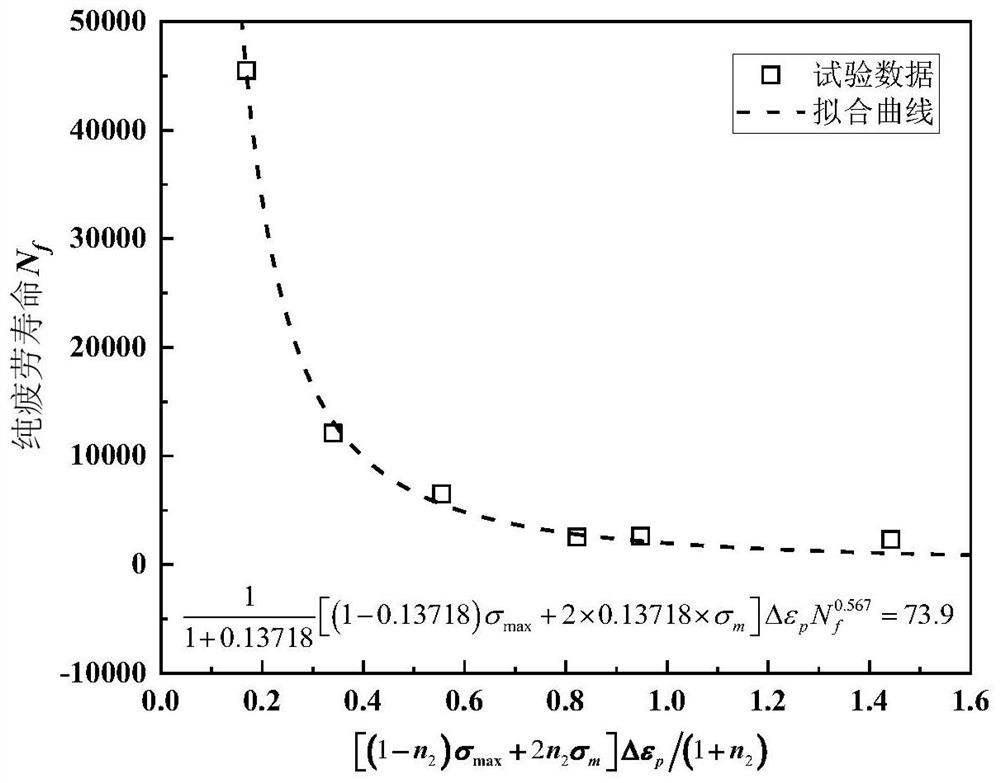

Method for predicting service life of high-temperature structural member based on nonlinear creep-fatigue interaction

ActiveCN114239175AOvercome limitationsImprove forecast accuracyGeometric CADNuclear energy generationFatigue damageStress level

The invention discloses a high-temperature structural member service life prediction method based on nonlinear creep-fatigue interaction, and the method comprises the following steps: constructing a service life prediction model which is used for carrying out the service life prediction of a high-temperature structural member through obtaining first creep damage based on threshold stress and second fatigue damage based on average stress; the method comprises the following steps: acquiring first creep damage by acquiring creep fracture strain energy, elastic modulus, stress level and peak strain retention time of a high-temperature structural member; second fatigue damage is obtained by obtaining the plastic strain range and average stress of the high-temperature structural part under the creep-fatigue condition, the plastic hardening index of the high-temperature structural part under the pure fatigue condition and the material constant of the high-temperature structural part; based on a life prediction model, according to the first creep damage and the second fatigue damage, life prediction is conducted on the high-temperature structural part; according to the method, the limitation of a bilinear creep-fatigue life prediction method is solved, and the prediction precision of the creep-fatigue life of the material is relatively high.

Owner:TIANJIN UNIV

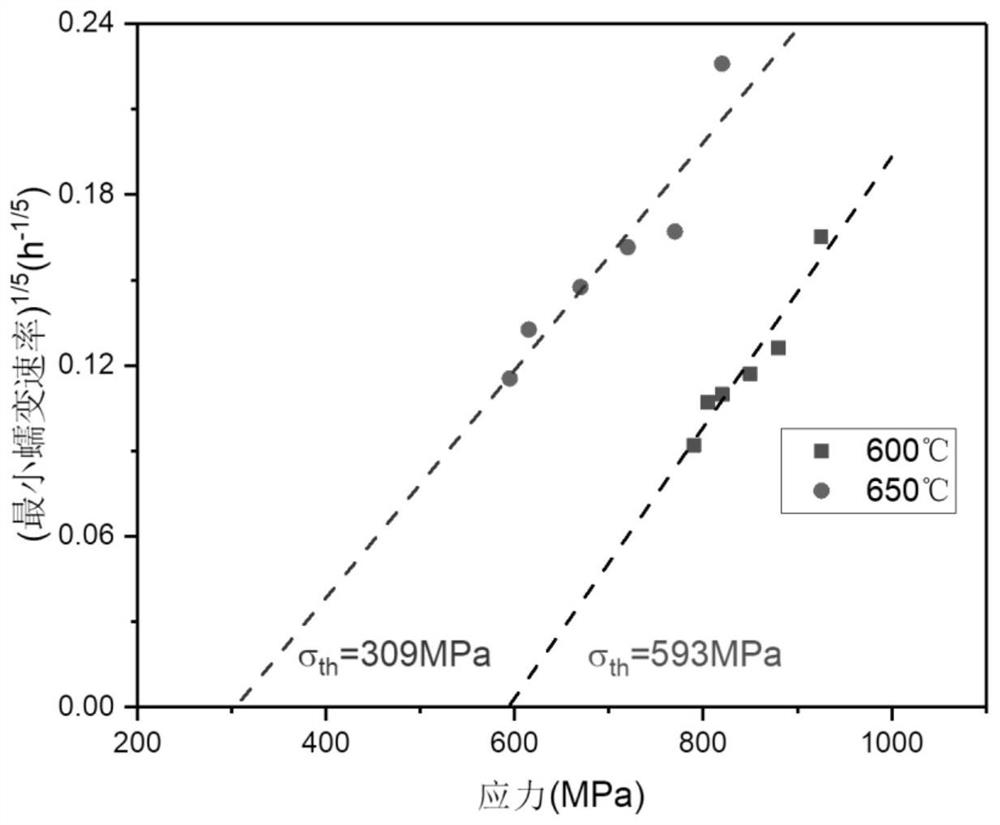

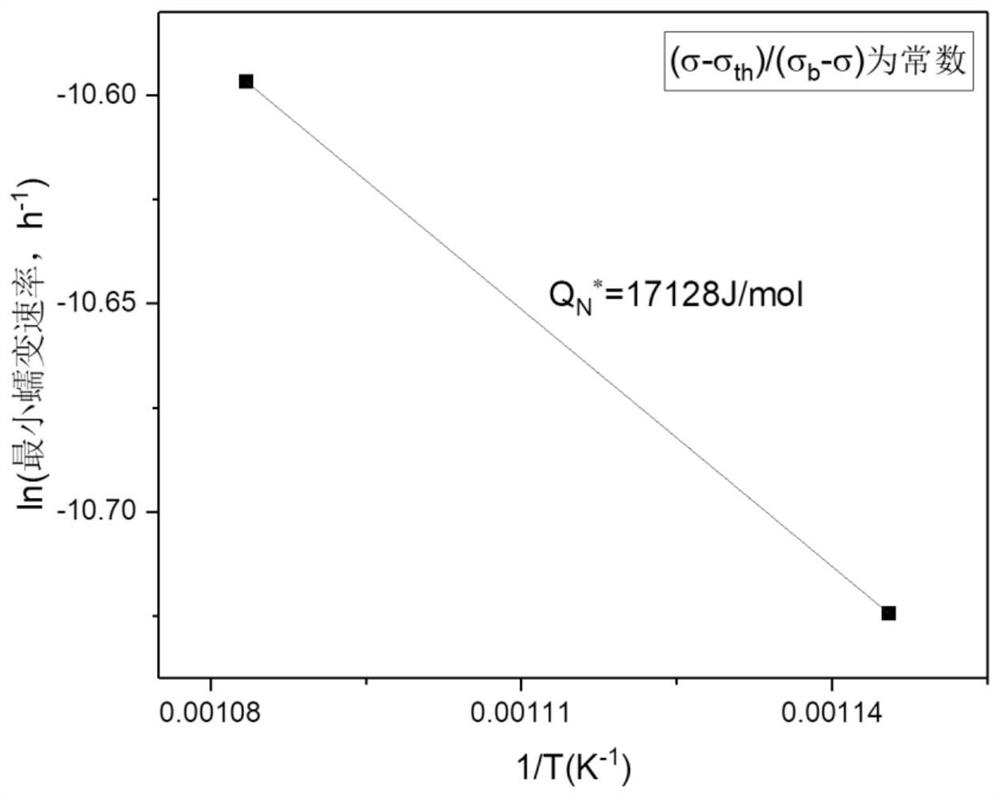

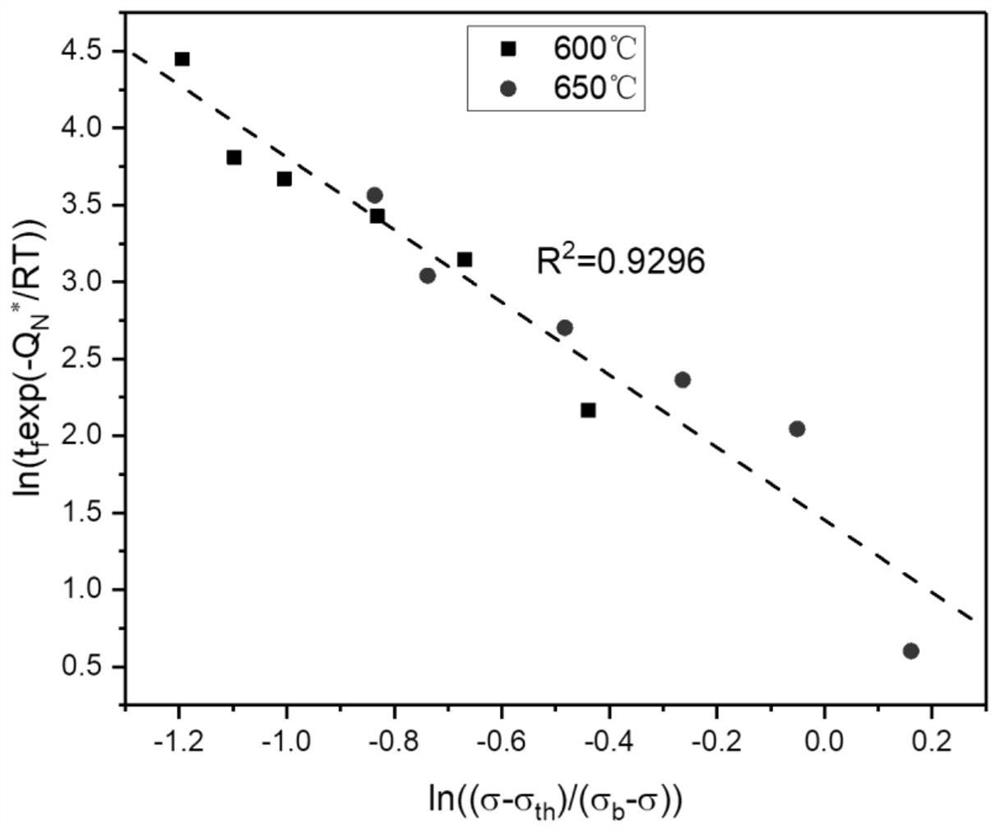

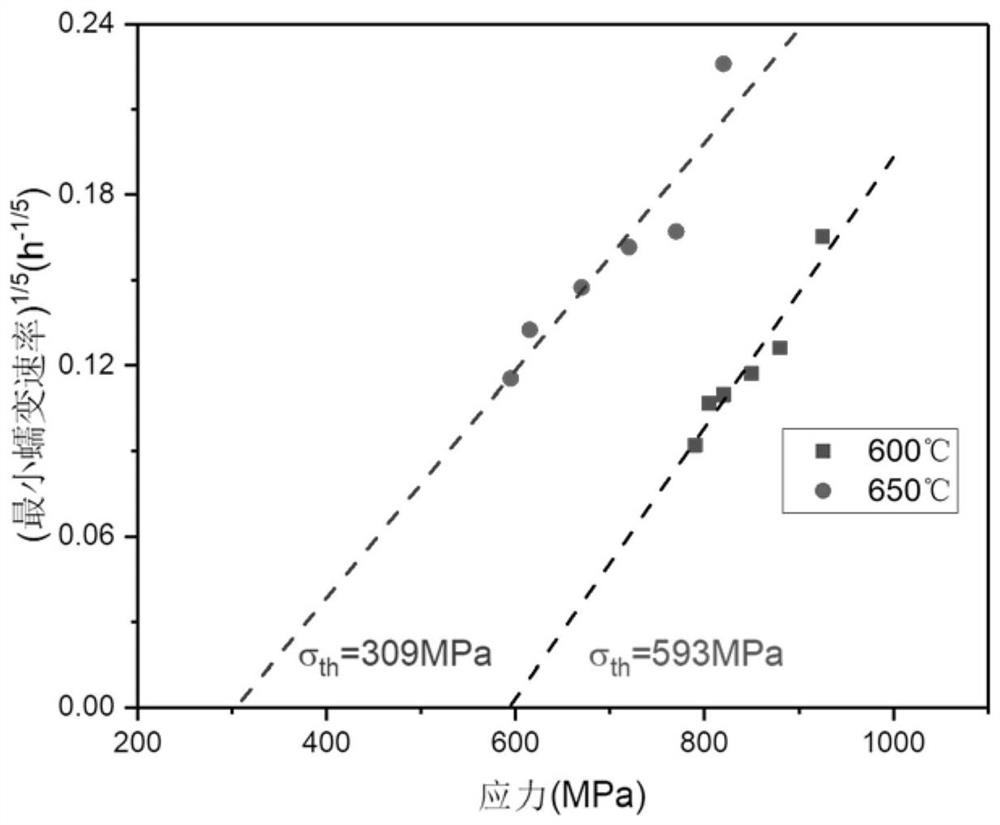

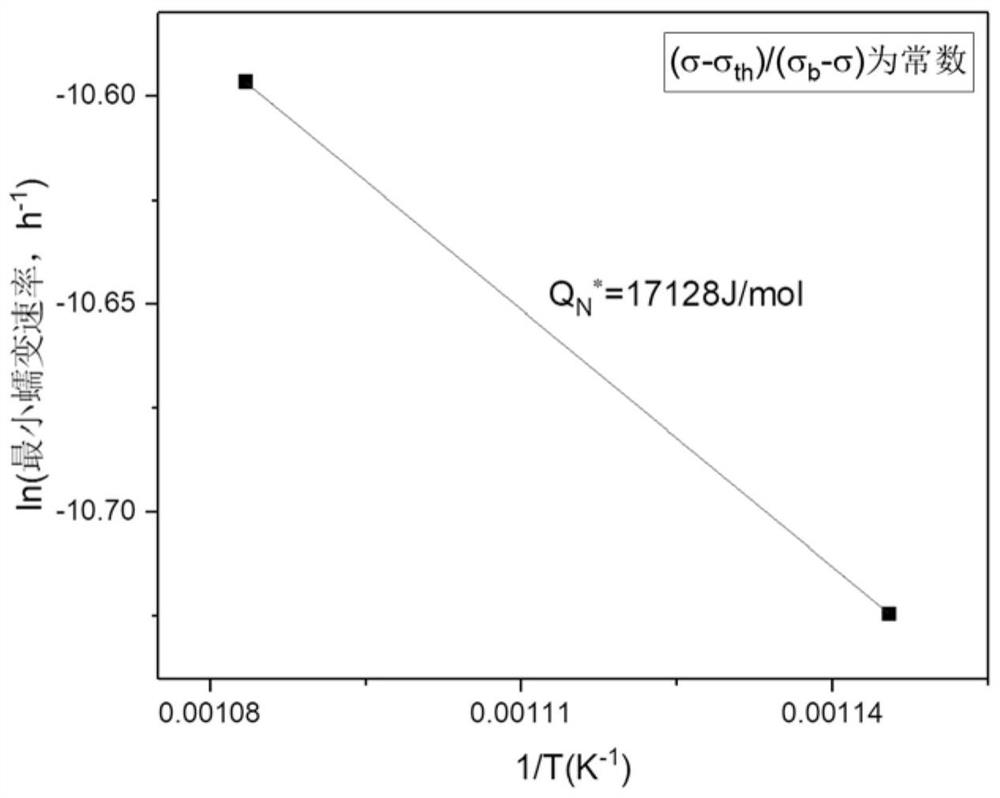

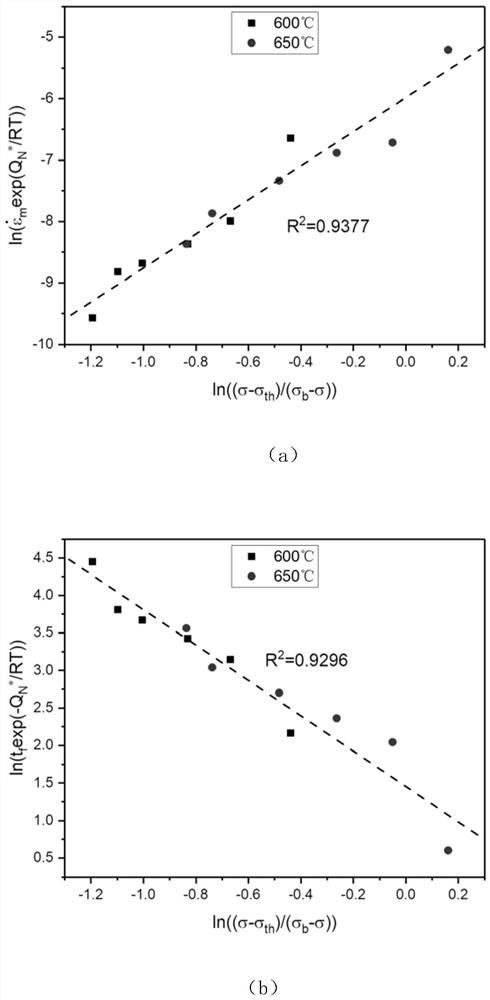

Creep life prediction method based on threshold stress and tensile strength

PendingCN113866008AFew parametersEasy to testMaterial strength using tensile/compressive forcesStructural engineeringThreshold stress

The invention discloses a creep life prediction method based on threshold stress and tensile strength, and the method comprises the following steps: 1, carrying out the high-temperature tensile test of a material at different temperatures T, and obtaining the tensile strength sigma b at the corresponding temperature; 2, carrying out a plurality of groups of high-temperature creep tests under different stress conditions at different temperatures to obtain the minimum creep rate and the creep life tf under the corresponding temperature stress conditions; 3, obtaining threshold stress sigma th corresponding to different temperatures according to the minimum creep rate; 4, establishing a function relationship between the threshold stress and the temperature based on the threshold stress sigma th at different temperatures; 5, on the basis of the threshold stress and the tensile strength, establishing a creep life prediction formula; and predicting the creep life under different stress temperature conditions through a creep life prediction formula. According to the method, the common influence of the threshold stress and the tensile strength is considered, the life prediction precision is high, and the extrapolation capability is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

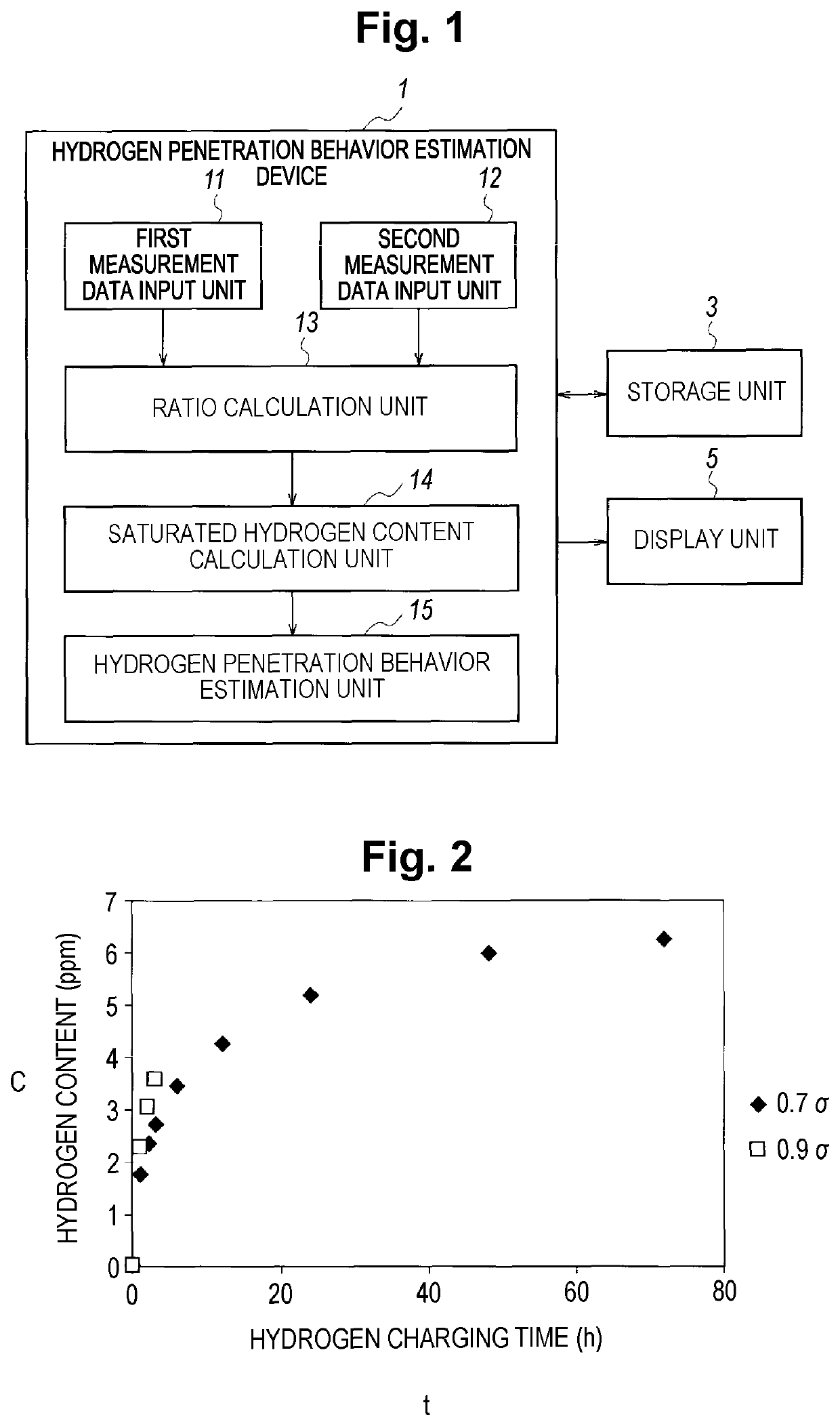

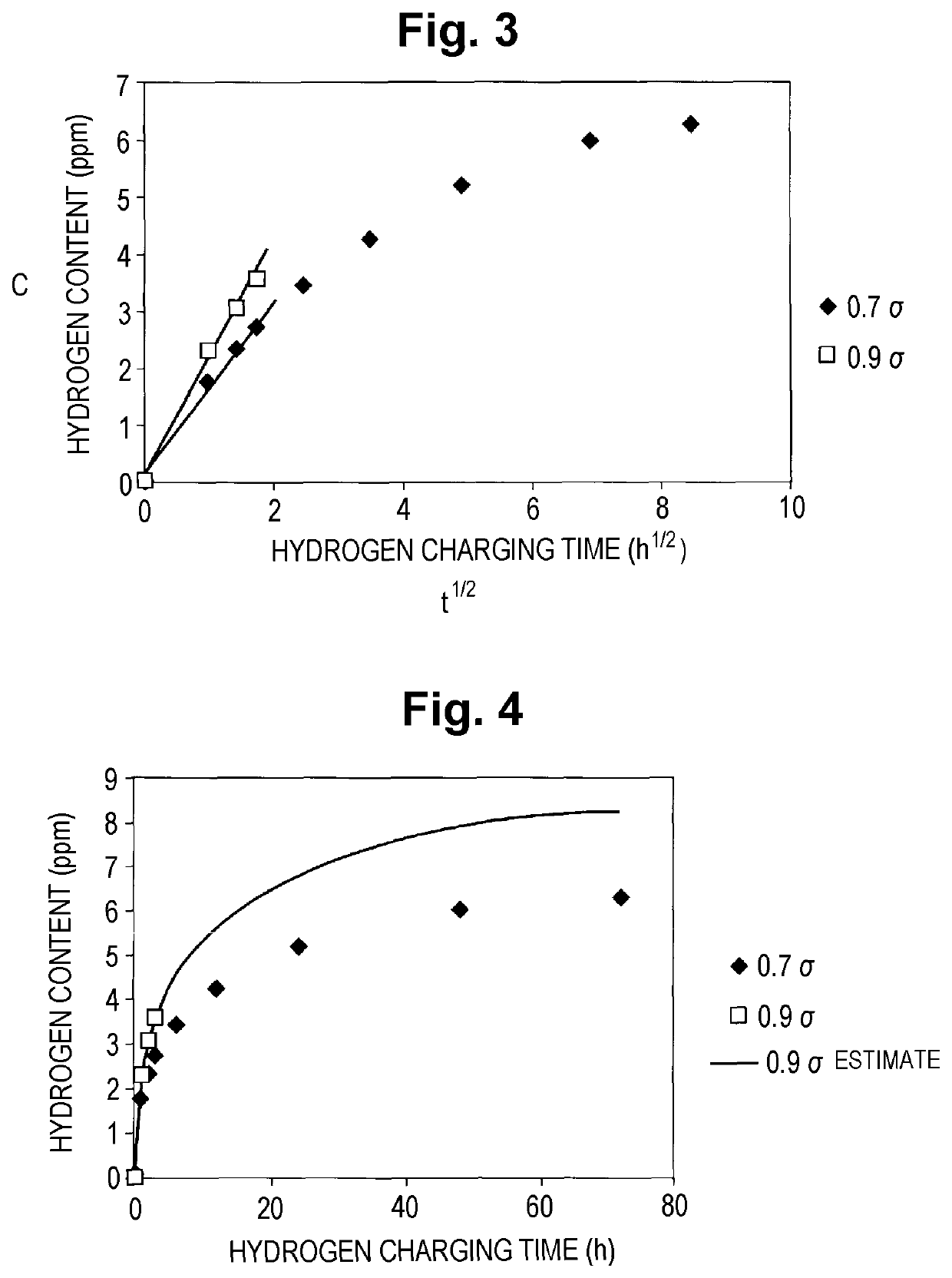

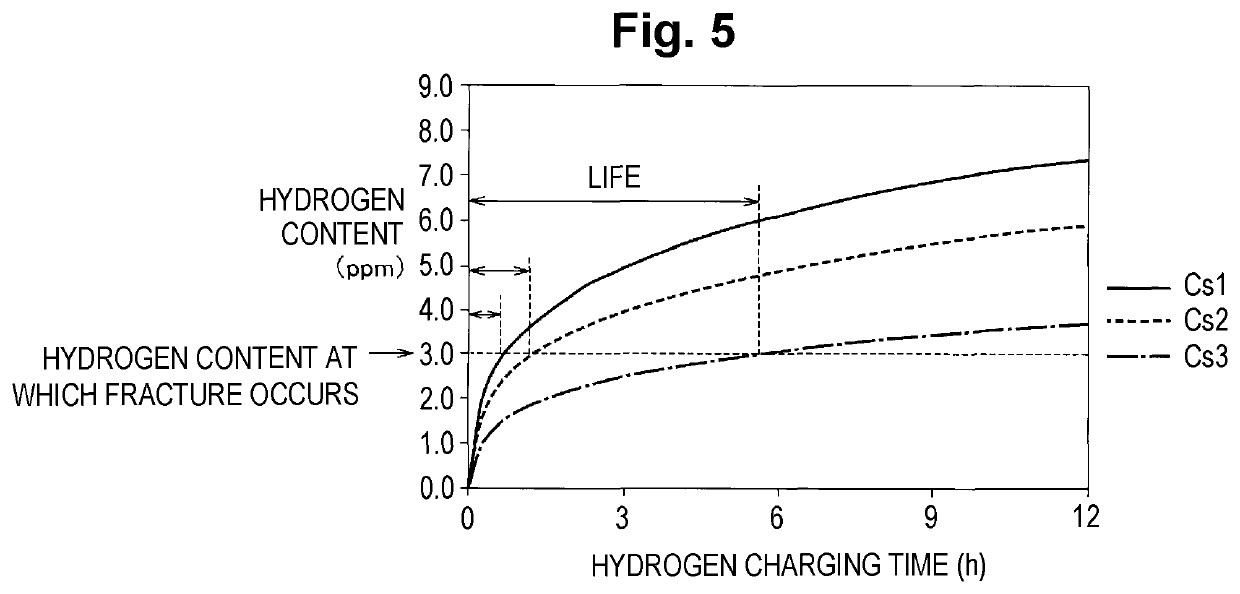

Method for estimating hydrogen absorption behavior, device for estimating hydrogen absorption behavior, and program for estimating hydrogen absorption behavior

To estimate penetration behavior of hydrogen up until hydrogen content reaches saturation even if load stress on steel is equal to or higher than threshold stress. A hydrogen penetration behavior estimation device includes a first measurement data input unit adapted to input first measurement data concerning variation of hydrogen content with time up until hydrogen content in steel-to-be-estimated reaches saturation when measurements are taken by applying such stress to the steel that no hydrogen embrittlement fracture occurs; a second measurement data input unit adapted to input second measurement data concerning variation of hydrogen content in the steel-to-be-estimated with time up until the steel fractures when measurements are taken by applying such stress to the steel that hydrogen embrittlement fracture occurs; a ratio calculation unit adapted to calculate increases in hydrogen contents in an initial stage of measurement and calculate a ratio of the second measurement data to the first measurement data in terms of increase in hydrogen content; and a saturated hydrogen content calculation unit adapted to multiply saturated hydrogen content based on the first measurement data by the ratio and designate the product as saturated hydrogen content of the steel-to-be-estimated, the saturated hydrogen content being reached upon application of such stress that hydrogen embrittlement fracture occurs.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

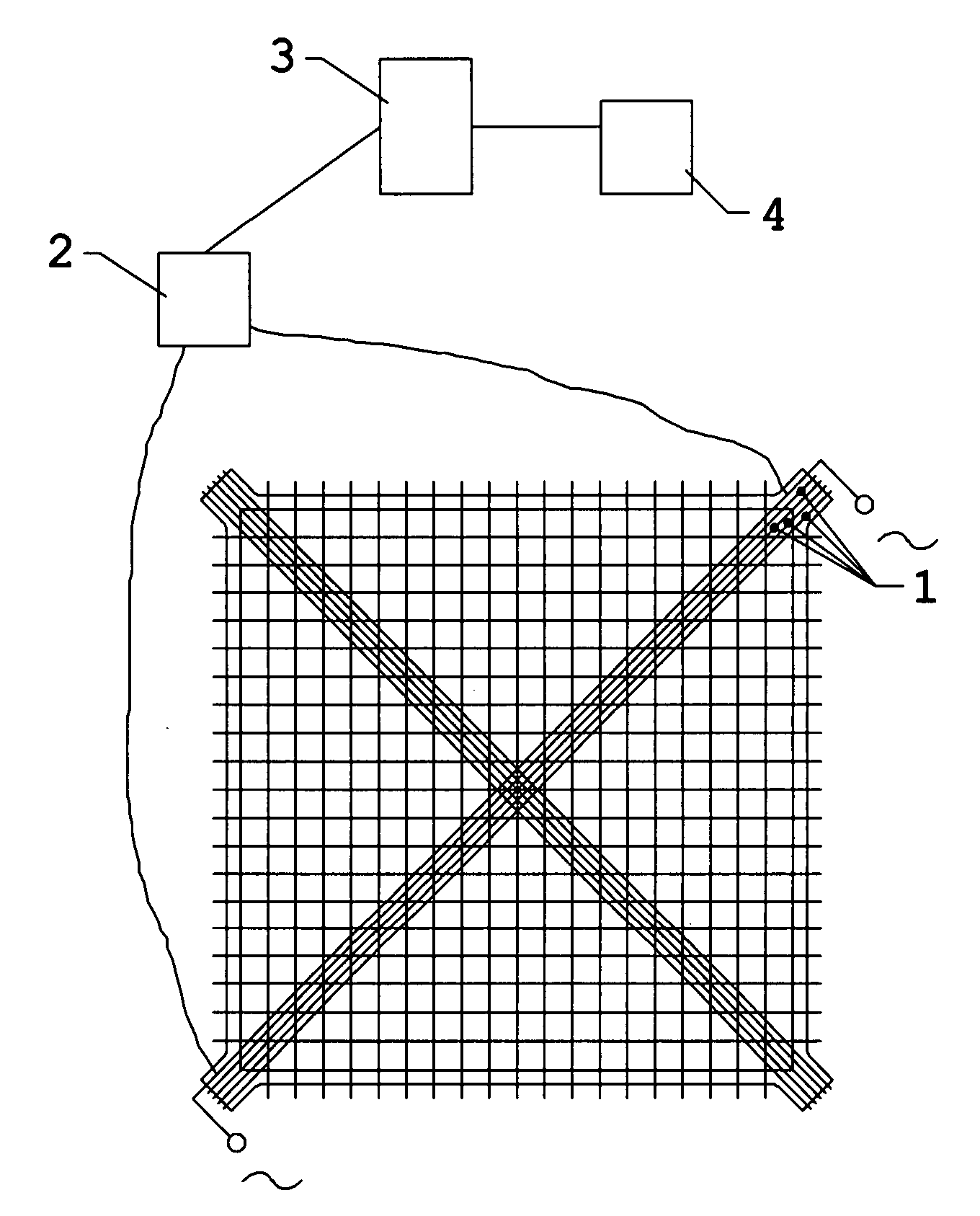

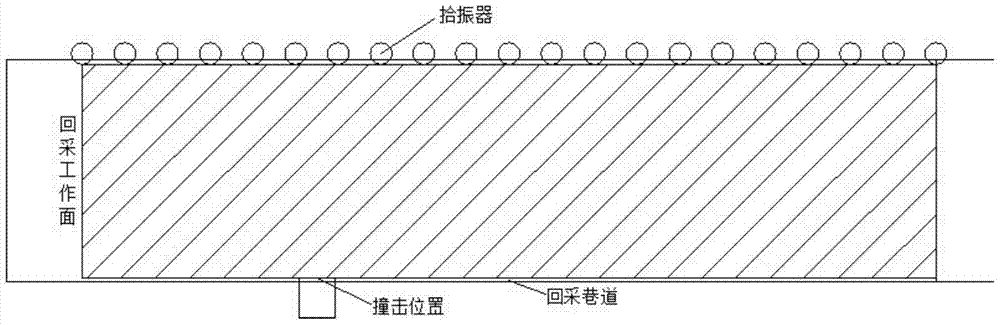

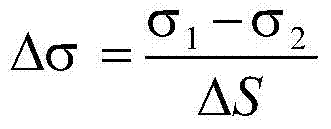

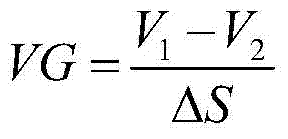

A Multi-information Coupling Prediction Method for In-situ Stress Type Rockburst Hazard

InactiveCN105045969BReal-time forecastImprove accuracySpecial data processing applicationsStress distributionTomography

The invention discloses a multi-information coupling prediction method for ground stress type rock burst risk. One side of the coal is blasted or hits the coal wall, and it is received by the pickup on the other side, and then CT tomography is used to obtain the distribution of the wave velocity gradient; (3) due to the coupling between the stress gradient and the wave velocity gradient, By determining the critical value of the stress gradient of the rock burst in the coal body, the critical value of the wave velocity gradient VGm is obtained; (4) In the process of coal mining, the wave velocity gradient VG in the coal body is obtained in real time through the formula; (5) The real-time The detected wave velocity gradient VG is compared with the wave velocity gradient critical value VGm. If VG is less than VGm, the prediction result is safe; if VG is greater than VGm, the prediction result is dangerous. It can predict the risk of rock burst in real time, and fully obtain the information of the outburst risk of rock burst.

Owner:CHINA UNIV OF MINING & TECH

Alloy vermicular cast iron for railway vehicle brake disc and its melting method

ActiveCN105483508BIncreased pearlite contentHigh strengthCompacted graphite ironStress concentration

The invention relates to an alloy vermicular cast iron for a railway vehicle brake disc and a melting method thereof. The chemical composition of the vermicular cast iron, in terms of mass percentage, includes: C: 3.3-3.5%, Si: 2.3-2.5%, Mn: 0.4~0.7%, Cu: 0.6~1.0%, Mo: 0.2~0.6%, Ni: 0.6~1.0%, P≤0.07%, S≤0.02%, and the balance of Fe, among them, vermicular graphite cast iron brake disc The creep rate is ≥75%, and the pearlite content is 50%-60%. The invention can increase the stress threshold value of disc cracking and expansion caused by thermal stress concentration, and improve the mechanical properties of the railway vehicle brake disc.

Owner:CHANGZHOU LANGRUI CASTING +1

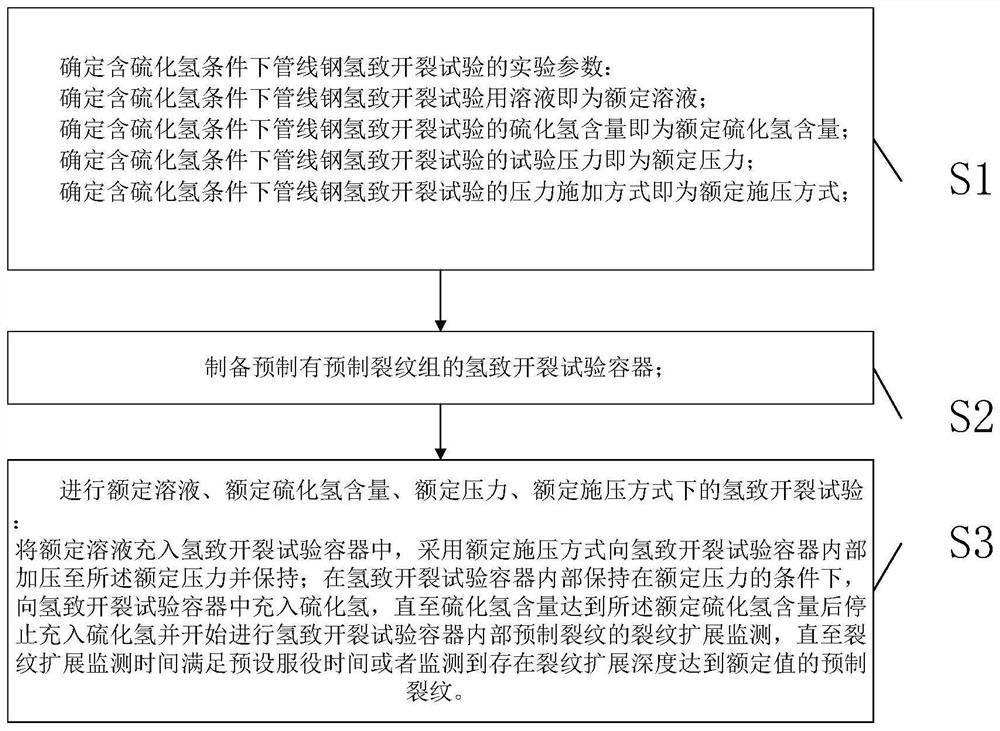

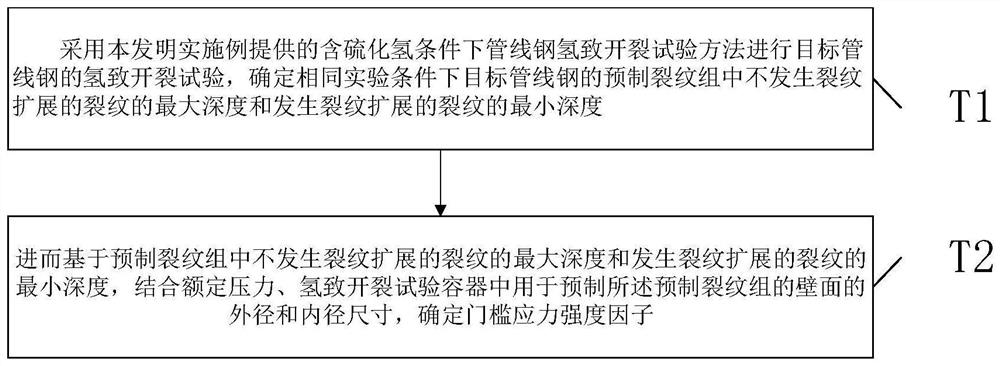

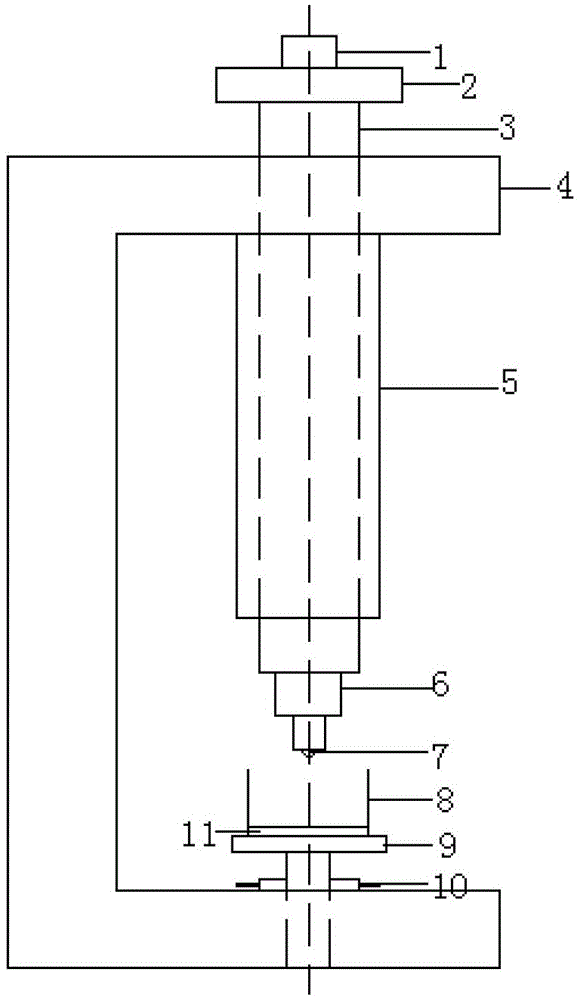

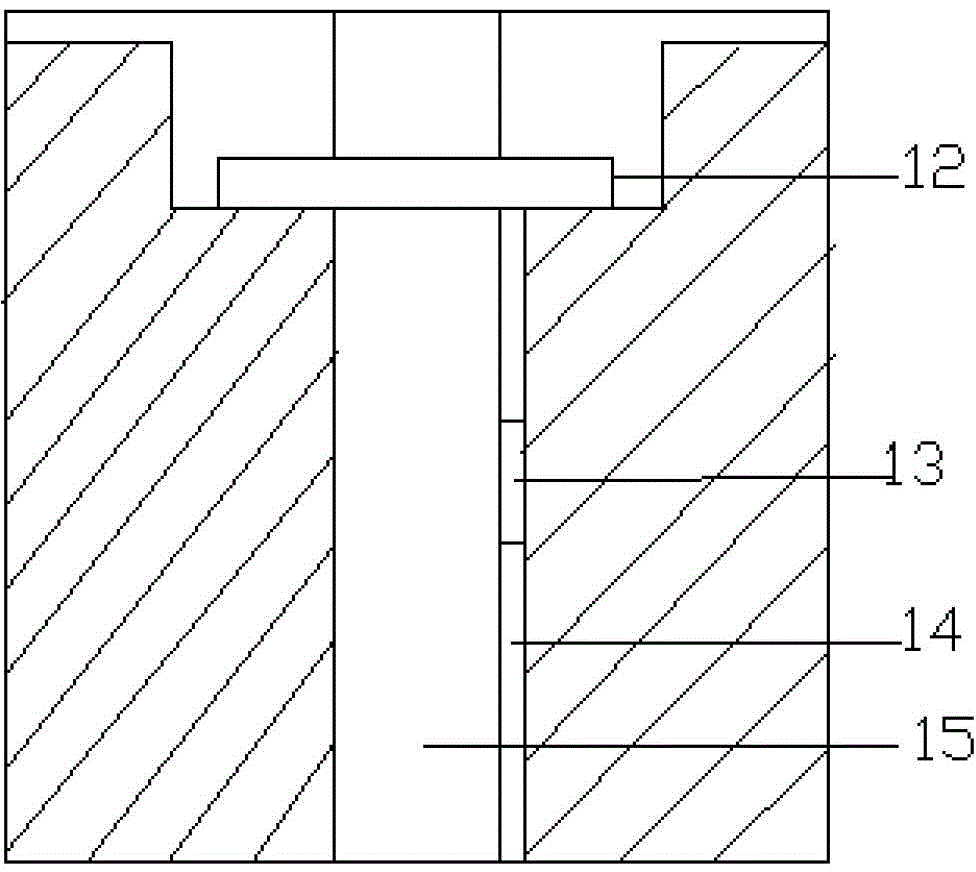

Device and method for testing hydrogen induced cracking of pipeline steel under hydrogen sulfide-containing condition and threshold stress intensity factor determination method

PendingCN114674670AAchieving Hydrogen-Induced Cracking BehaviorMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention discloses a device and a method for testing hydrogen induced cracking of pipeline steel under a hydrogen sulfide-containing condition and a method for determining a threshold stress intensity factor. The device comprises a hydrogen induced cracking test container, a pressure test pump and a hydrogen sulfide storage tank, the hydrogen induced cracking test container is made of target pipeline steel, and at least one group of prefabricated cracks are prefabricated on the inner wall; each prefabricated crack group consists of at least two prefabricated cracks with different depths; and the pressure test pump and the hydrogen sulfide storage tank are connected with the hydrogen induced cracking test container. The test method comprises the following steps: determining experimental parameters of a pipeline steel hydrogen induced cracking test under a hydrogen sulfide-containing condition; preparing a hydrogen induced cracking test container prefabricated with a prefabricated crack group; and carrying out a hydrogen induced cracking test. The determination method comprises the following steps: performing a hydrogen induced cracking test on target pipeline steel, and determining the maximum depth of a crack without crack propagation and the minimum depth of a crack with crack propagation; and further determining a threshold stress intensity factor.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Prediction method for creep damage and deformation evolution behavior along with time

PendingCN114295491AHigh precisionFew parametersMaterial strength using tensile/compressive forcesCreep strainEngineering

The invention discloses a method for predicting creep damage and deformation evolution behaviors along with time, which comprises the following steps of: obtaining tensile strength sigma b through a high-temperature tensile test of a material; a corresponding creep strain curve, the minimum creep rate and the creep life tf are obtained through a high-temperature creep test; obtaining threshold stress sigma corresponding to different temperatures; establishing a function relationship between the tensile strength sigma b and the temperature T and between the threshold stress sigma th and the temperature T; respectively establishing a minimum creep rate and creep life tf prediction formula based on the threshold stress sigma and the tensile strength sigma ; establishing a creep damage constitutive model, wherein the creep damage constitutive model comprises a strain rate formula and a damage rate formula; obtaining an evolution behavior of strain deformation along with time by solving a strain rate formula; and obtaining the evolution behavior of the damage along with time by solving a damage rate formula. According to the method, the defect that a traditional creep damage constitutive model is difficult to extrapolate is overcome, accurate extrapolation can be achieved, and the prediction precision is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Stress corrosion test method for metal sheet pre-cracked sample

InactiveCN102103063BLower requirementSave materialWeather/light/corrosion resistanceMetallic materialsMetal sheet

The invention discloses a stress corrosion test method and a stress corrosion test device for a metal sheet pre-cracked sample. The method comprises the following steps of: fixing one end of the sample on a bearing wall, clamping the other end of the sample by using an upper clamping plate and a lower clamping plate and fixing; clamping a test section of the sample by using a corrosion environment test box; pre-estimating the initially applied stress field intensity factor according to the threshold stress field intensity factor of crack propagation of similar metal materials, wherein the pre-estimated value is greater than the threshold stress field intensity factor of the crack propagation of the metal materials; loading stress to the metal sheet sample, measuring the crack length of the sheet sample to obtain a crack stress field intensity factor, and stopping loading the stress when the crack stress field intensity factor is equal to the pre-estimated value; filling a corrosion medium in the corrosion environment test box; measuring the length of a crack at the tip of the pre-cracked sample at intervals of certain time; and measuring the crack length and the loaded stress after the crack stress field intensity factor is stabilized to obtain the threshold stress field intensity factor of stress corrosion crack propagation. The method is convenient to operate and high in measuring accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Measuring Method for Tensile Stress Corrosion of Deformed Aluminum Alloy

ActiveCN108398320BReasonable testComprehensive testingWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesAlcladThreshold stress

The invention discloses a method for measuring stretching stress corrosion of a deforming aluminium alloy. The method comprises the following steps: removing an alclad layer on the surface of a sample; measuring stress corrosion sensitivity through relative change of same mechanics parameters of the same sample exposed under contrast test environment and exposed under inertia environment; and measuring the threshold stress of stress corrosion according to a binary search method. The method for measuring the stretching stress corrosion of the deforming aluminium alloy is capable of performing quantification measurement on stress corrosion sensitivity of the aluminium alloy.

Owner:CASIC DEFENSE TECH RES & TEST CENT

A continuous loading indentation type stress corrosion test machine and test method

InactiveCN103163035BLow costImprove stabilityWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceHysteresisWorkstation

Owner:UNIV OF SCI & TECH BEIJING

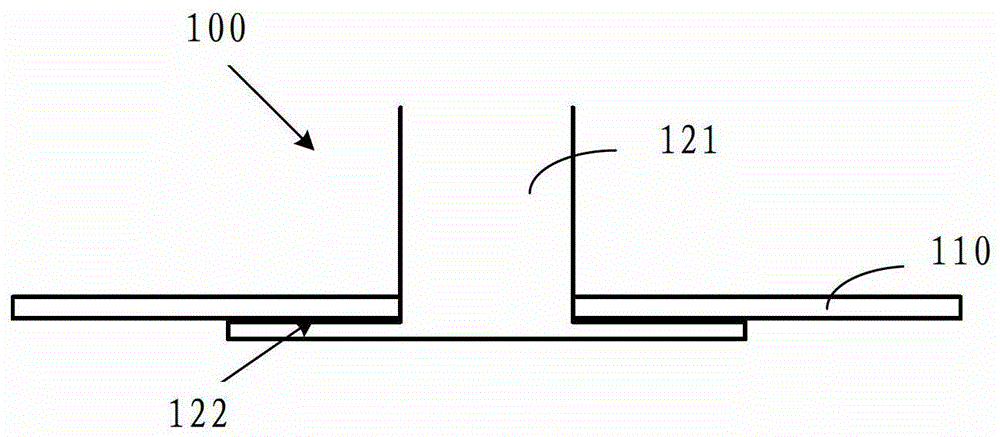

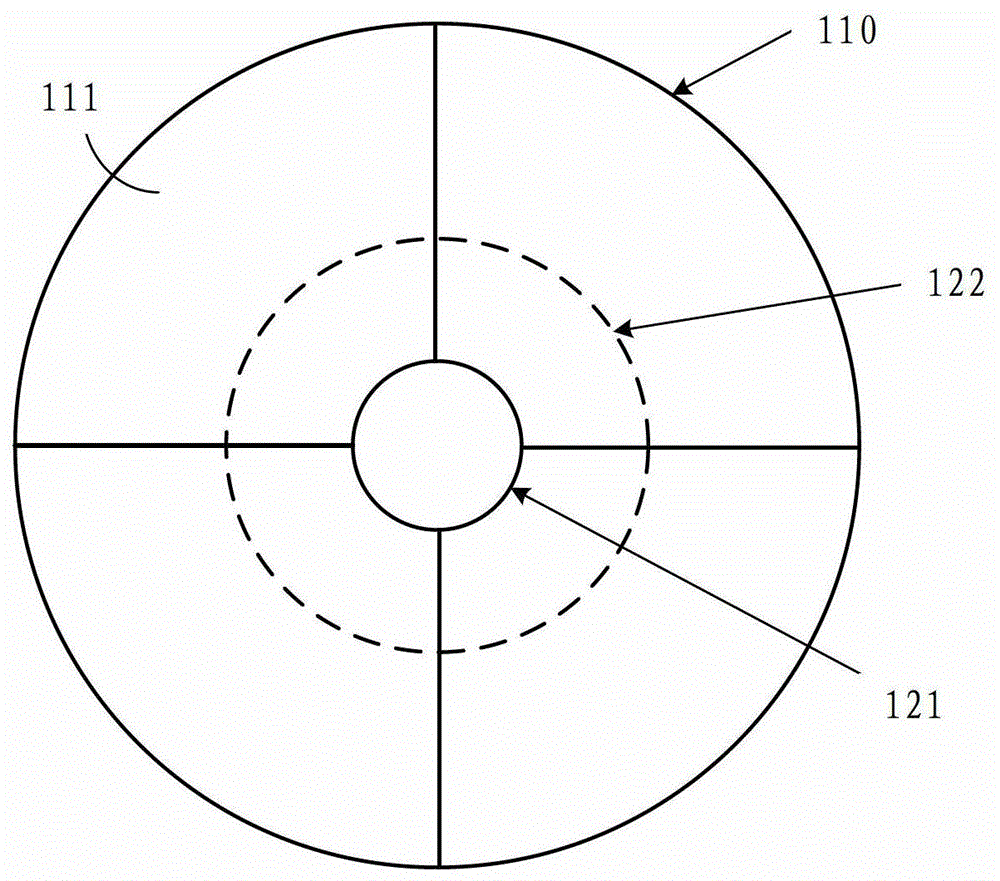

Optical sheet wheel, light source system and projection system

The embodiment of the invention discloses an optical sheet rotating wheel, a light source system and a projection system. The optical sheet rotating wheel includes a rotating shaft and a fixed surface fixed on the rotating shaft; The outer diameter of the optical sheet is larger than the outer diameter of the fixed surface; the fixed surface includes two hollow areas, and each hollow area is equipped with a dispensing area and a beam group, and each dispensing area only passes through the beam group and the non-hollowed out area. The areas are connected and fixed, and the beam group includes at least one beam; the optical device is fixed to the fixed surface only by bonding with the dispensing area; the stiffness of the beam group in each hollow area along the radial direction passing through the center of the dispensing area The coefficient is less than the first predetermined value, so that when the branch beam group is deformed under the predetermined temperature difference, the stress on the optical device along the radial direction through the dispensing area is less than or equal to the critical value, so that the stress on the optical device is less than the stress that causes it to break. Stress critical value. The invention can provide an optical sheet rotating wheel which prevents the optical sheet from being pulled.

Owner:峰米(北京)科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com