Prediction method for creep damage and deformation evolution behavior along with time

A technology of time evolution and prediction method, which is applied in the direction of testing the strength of materials by applying stable tension/pressure, which can solve the problems of difficulty in quantifying creep damage, lack of clear definition of correlation, and difficulty in continuous characterization, etc. The effect of low cost, strong interpolation and extrapolation capabilities, and few parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] In this embodiment, the creep damage and deformation prediction method of the present invention is applied to the creep damage and deformation prediction of the nickel-based superalloy GH4169 material, including the following steps:

[0081] (1) The high temperature tensile test of GH4169 material was carried out at 600°C and 650°C, and the corresponding tensile strengths were 1440MPa and 1255MPa respectively.

[0082] (2) Carry out high-temperature creep tests of GH4169 material under 6 different stress values at 600°C and 650°C respectively, and obtain the corresponding creep strain curve and minimum creep rate and the creep life t f . The specific test plan and the obtained test data are shown in Table 1.

[0083] Table 1 GH4169 material creep test scheme and data

[0084]

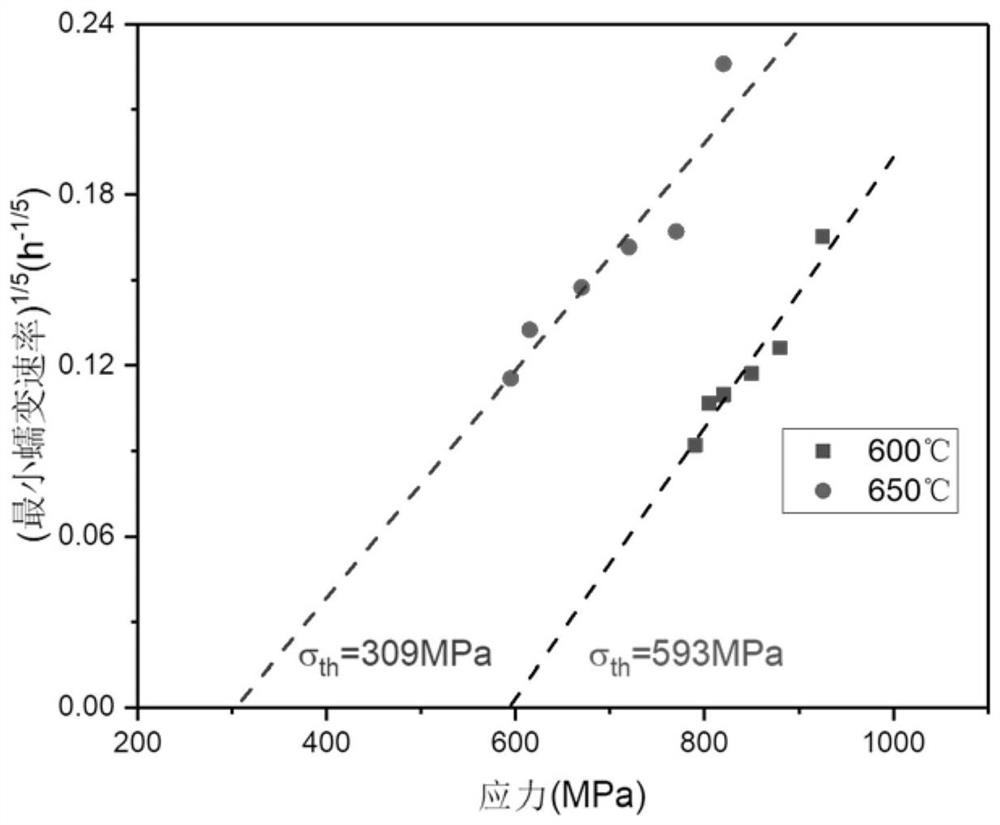

[0085] (3) Using the formula Linear fit at 600°C and 650°C, respectively -σ data, the stress value corresponding to the intersection of the fitting line and the X-axis is the threshold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com