Stress corrosion test method for metal sheet pre-cracked sample

A metal sheet, stress corrosion technology, applied in the field of electrochemical measurement, can solve the problems of lack of pertinence, conservative test results, lack of engineering application value, etc., to achieve the effect of convenient operation, shortening test time and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

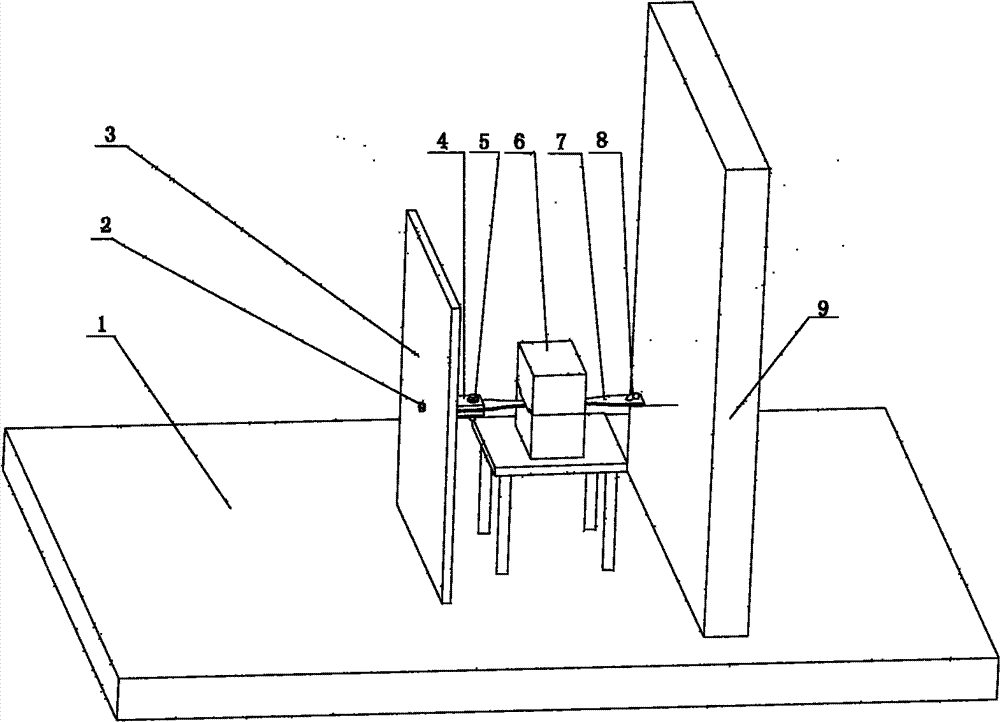

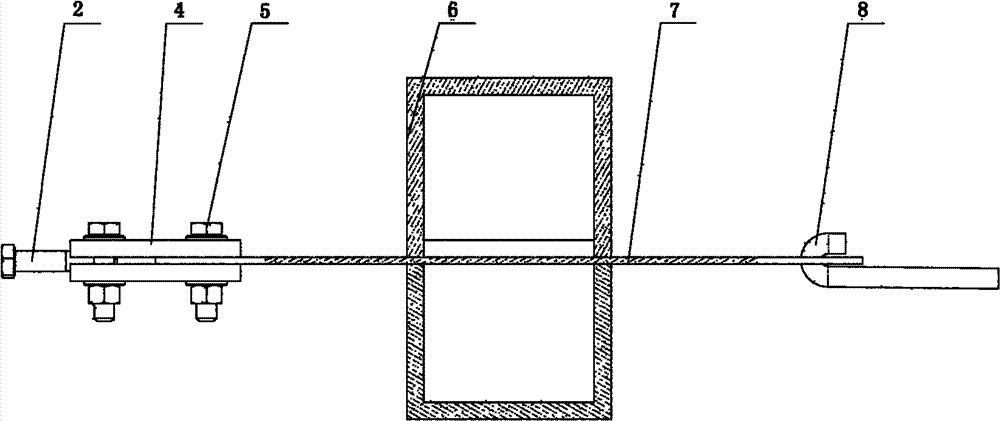

[0025] Below in conjunction with accompanying drawing, metal sheet pre-crack sample stress corrosion test method and device of the present invention are further described:

[0026] figure 1 It is a schematic diagram of the structure of the stress corrosion test device for the pre-cracked sample of the metal sheet. figure 2 for figure 1 Sectional view along the central axis. refer to Figure 1-2 As shown, the metal sheet pre-crack sample stress corrosion test device, wherein the fixed hook 8 is installed on the load-bearing wall 9, the upper and lower splints 4 are horizontally installed on the side of the baffle 3 facing the fixed hook, and three holes are opened on the splint. A triangular hole, the bolt passes through the hole to compress the splint to fix the sample, and a hole is opened on the baffle 3 corresponding to the middle of the upper and lower splints, and the screw rod of the loading screw 2 is first fitted with a pressure sensor and then passes through the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com