Optical sheet wheel, light source system and projection system

An optical sheet and runner technology, which is applied in the field of lighting and display, can solve the problem of heating of the filter 110 bracket, and achieve the effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

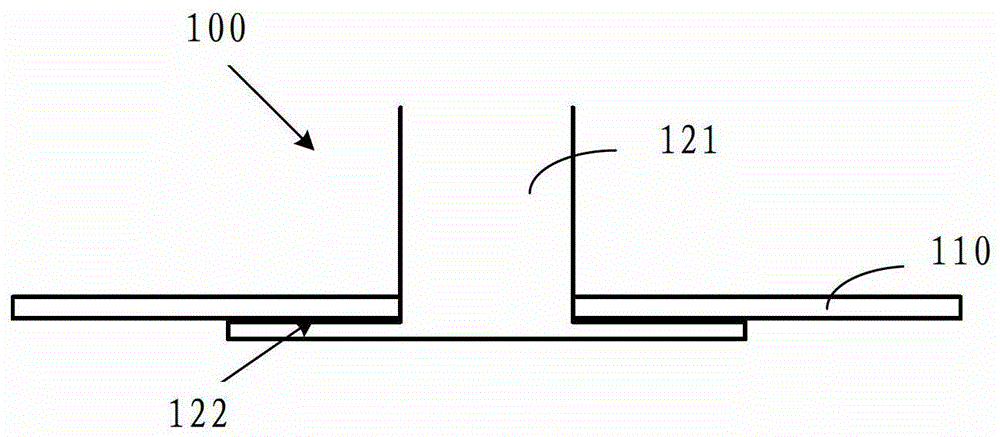

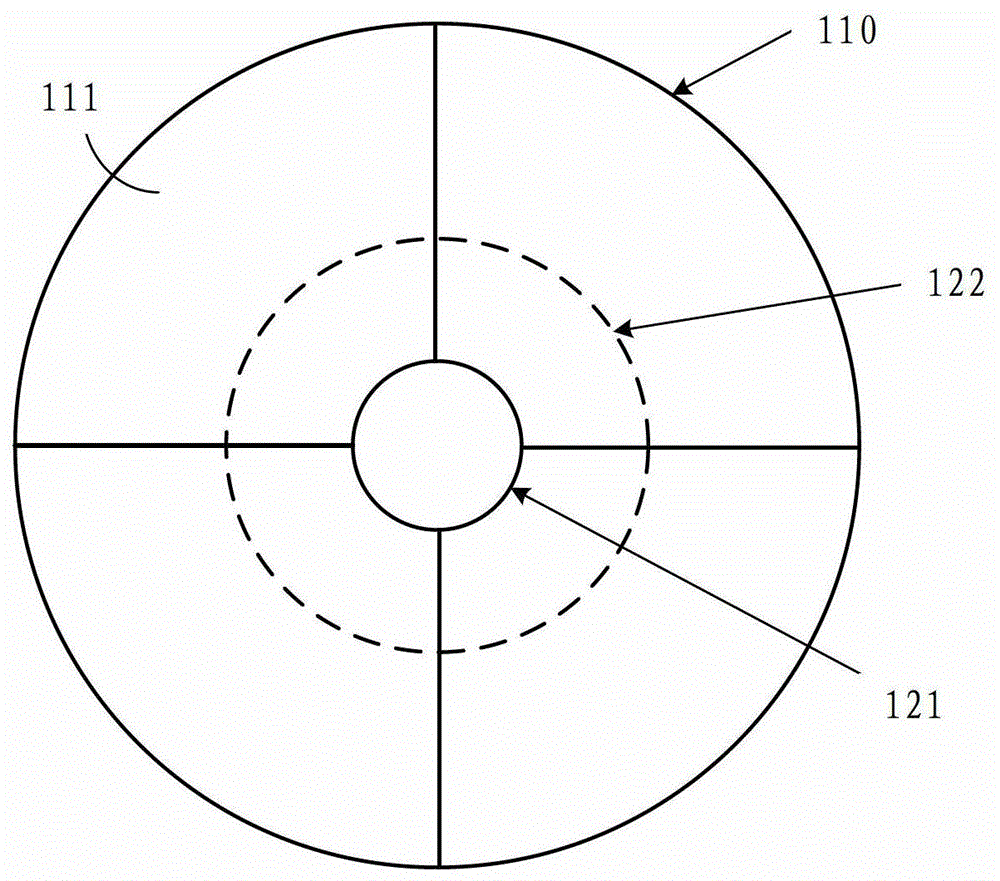

[0044] see Figure 2A , Figure 2A It is a structural schematic diagram of an embodiment of the optical sheet rotating wheel of the present invention. The optical sheet rotating wheel includes an optical device and a driving device 2 for driving the optical device to rotate.

[0045] The optical device includes a circular optical sheet 11 . Such as Figure 2B as shown, Figure 2B yes Figure 2A Bottom view of the optical setup in the optical sheet wheel shown. In this embodiment, the optical sheet 11 is assembled by splicing four sub-optical sheets 11 a ringed on the rotation axis 21 and perpendicular to the rotation axis 21 . In this embodiment, the optical sheet 11 may include at least one of a filter, a diffuser, a light-transmitting sheet, and a reflective sheet, which are respectively used to filter, scatter, transmit, or reflect light beams. The optical sheet 11 is generally made of glass material. It is worth noting that the number of sub-optical sheets in the o...

Embodiment 2

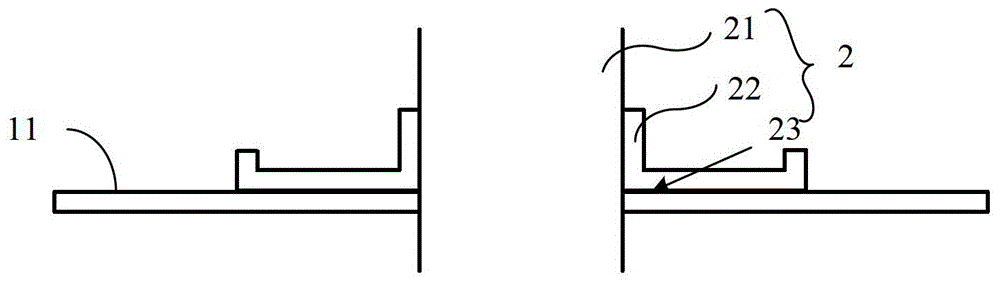

[0068] In Embodiment 1, each sub-optical sheet in the optical sheet is directly bonded to the fixed surface to form a ring-shaped optical sheet. During the high-speed rotation of the optical sheet rotating wheel, the glue between each sub-optical sheet and the fixed surface provides centripetal force for each sub-optical sheet, so that the optical sheet rotates accordingly. The greater the rotational speed of the optical sheet wheel, the greater the centripetal force. However, since the optical sheet is not a complete whole, when the glue is not hard enough, each sub-optical sheet will fly out. This embodiment provides a solution to this problem.

[0069] see Figure 4 , Figure 4 It is a structural schematic diagram of another embodiment of the optical sheet rotating wheel of the present invention. The optical sheet rotating wheel includes an optical device 1 and a driving device 2 for driving the optical device 1 to rotate.

[0070] The difference between this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com