Method for constructing forming limit stress diagram of metal sheet

A technology of forming limit and sheet metal, which is used in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, sampling, etc. It can solve the problem of difficulty in measuring stress, and achieve the effect of solving the difficulty of direct measurement of stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

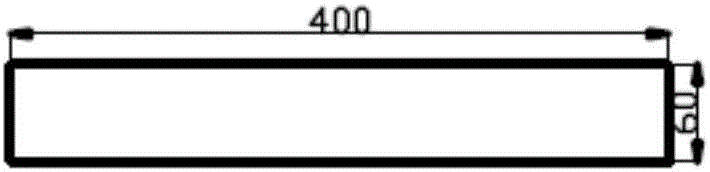

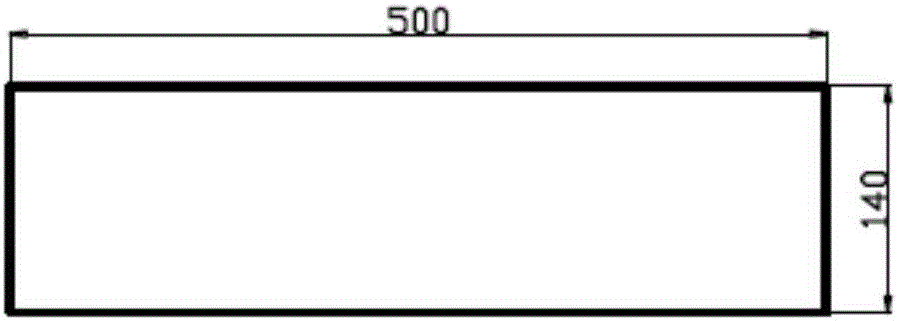

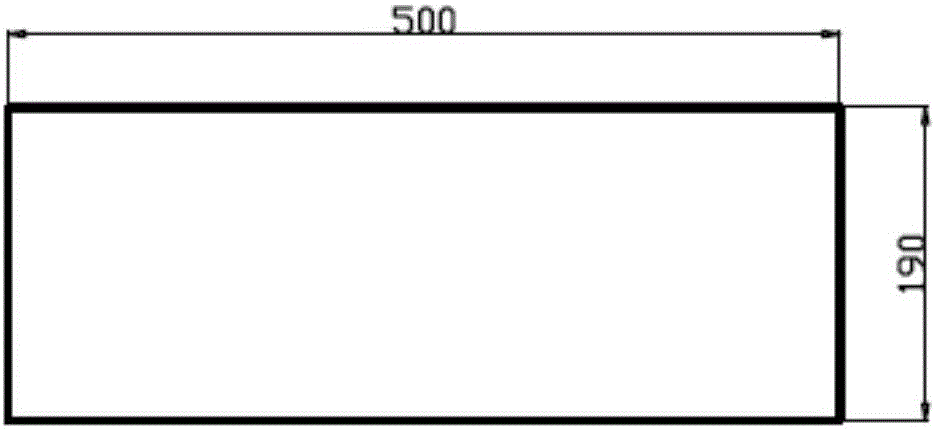

[0030] 1. Put the DP780+Z high-strength steel with a thickness of 0.9mm according to the following figure 1 , figure 2 , image 3 Dimensions shown are cut into pre-uniaxial tensile specimens according to Figure 5 Dimensions cut into pre-plane strain specimens, according to Figure 6 The dimensions are cut into pre-biaxial tensile strain specimens;

[0031] 2. Use the electrolyte corrosion method to print grids or speckles in the uniformly deformed area in the middle of the sample;

[0032] 3. Pre-strain the sample. The pre-uniaxial tension was realized by a triaxial loading test machine, and the figure 1 , figure 2 , image 3 The specimens shown were subjected to uniaxial tension with a predetermined amount of strain, and the pre-plane strain and pre-biaxial tensile strains were Figure 7 Schematic of the hemispherical rigid punch bulge test setup. The principal strain ε of the pre-strained specimen is measured by an off-line or on-line strain measurement system 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com