Device and method for testing hydrogen induced cracking of pipeline steel under hydrogen sulfide-containing condition and threshold stress intensity factor determination method

A technology of cracking test and hydrogen sulfide, applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve a large number of experimental accumulation, difficult actual site conditions, matching and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

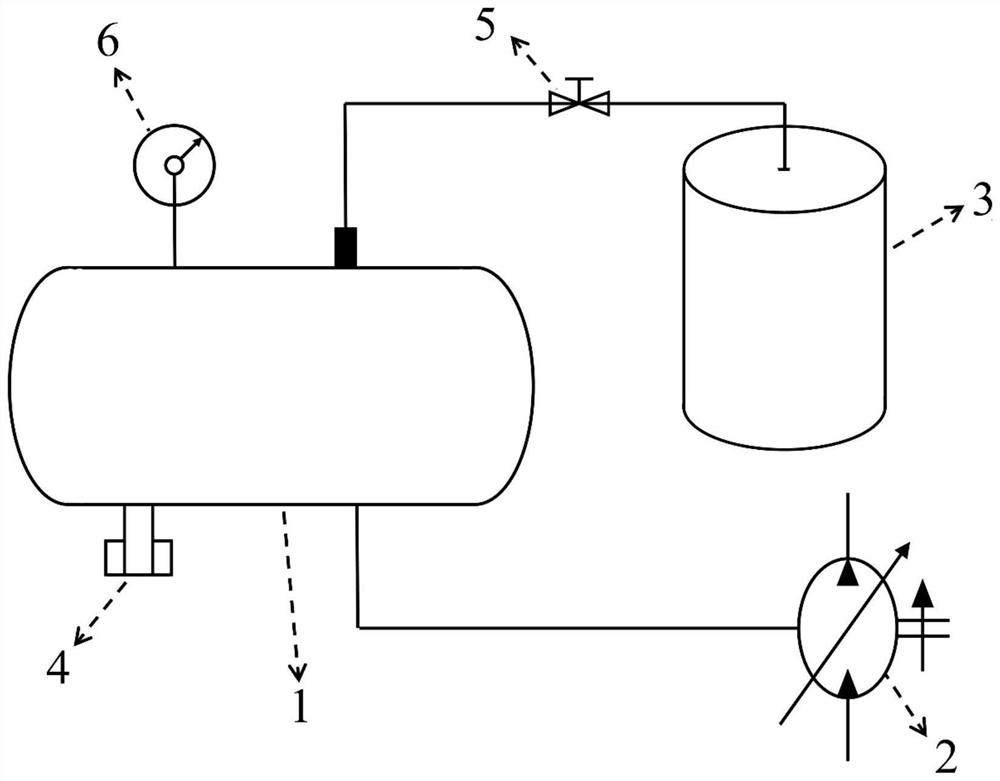

[0226] The present embodiment provides a hydrogen-induced cracking test device for pipeline steel under the condition of containing hydrogen sulfide, wherein the device includes:

[0227] Hydrogen-induced cracking test container, pressure test pump, hydrogen sulfide storage tank, one-way ventilation valve, barometer;

[0228] Among them, the hydrogen-induced cracking test container is made of the target pipeline steel; the hydrogen-induced cracking test container includes a tubular side wall and two end surfaces, the two end surfaces are arranged at both ends of the tubular side wall, and the tubular side wall and the two end surfaces are enclosed to form a closed The outer diameter of the tubular side wall is the same as the outer diameter of the pipeline made when the target pipeline steel is in service, and the inner diameter of the tubular side wall is the same as the inner diameter of the pipeline made when the target pipeline steel is in service; A group of prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com