Method for predicting service life of high-temperature structural member based on nonlinear creep-fatigue interaction

A technology of life prediction and interaction, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as large errors in creep-fatigue life prediction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

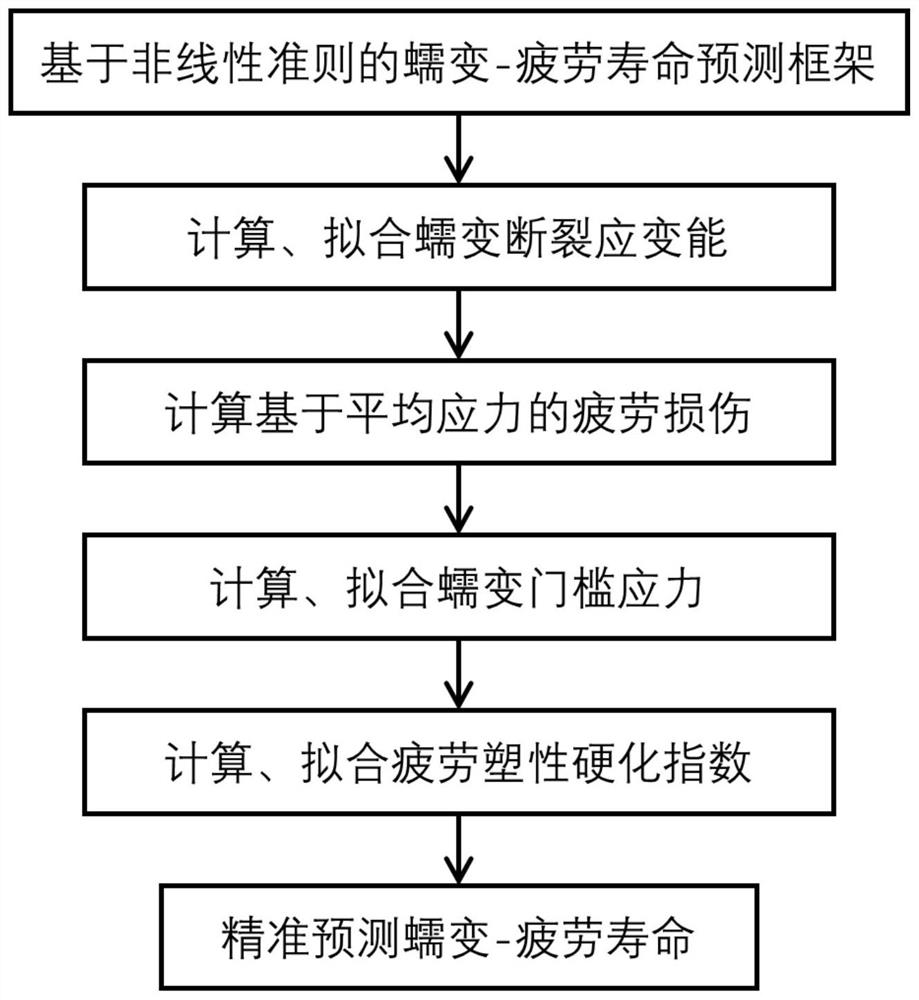

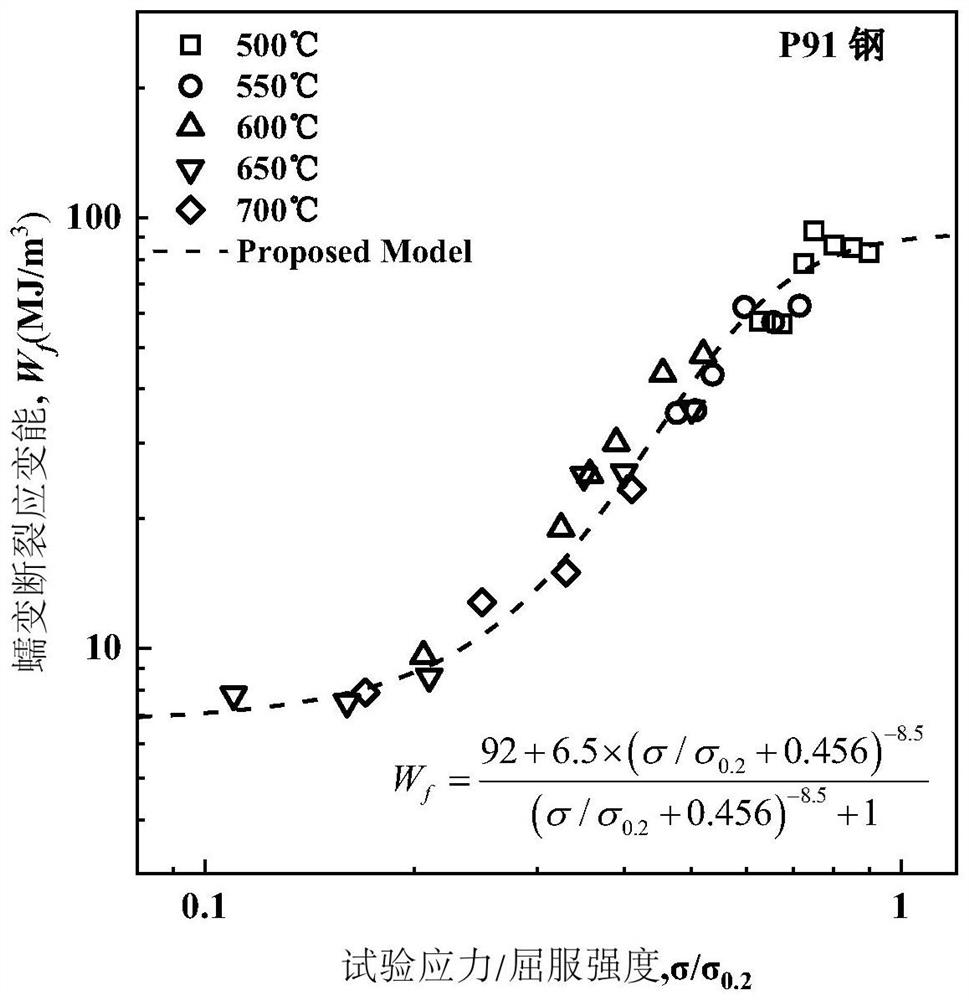

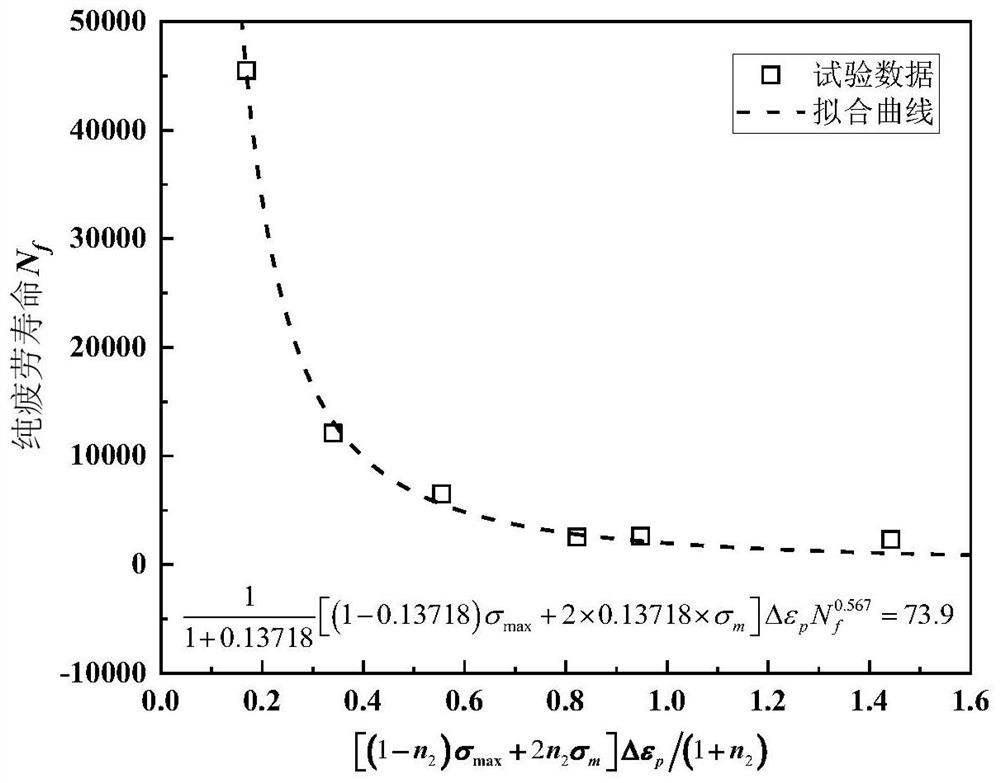

[0085] Example 1: See figure 1 As shown, the life prediction method of high temperature structural parts provided by the present invention includes: creep damage prediction method based on threshold stress, fatigue damage prediction method based on average stress and creep-fatigue life prediction method under nonlinear interaction conditions. The present invention is further explained through pure creep test, pure fatigue test and creep-fatigue test. The test material is P91 martensitic heat-resistant steel, and the test temperature is 550°C. The creep-fatigue test adopts strain loading, and at the peak The strain is maintained, and the loading waveform is a trapezoidal wave.

[0086] In step (1), a life prediction method based on nonlinear creep-fatigue interaction under creep-fatigue test conditions is proposed:

[0087]

[0088] where D c is the creep damage based on the threshold stress, D f is the creep damage based on the mean stress. D. c and D f The specific e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com