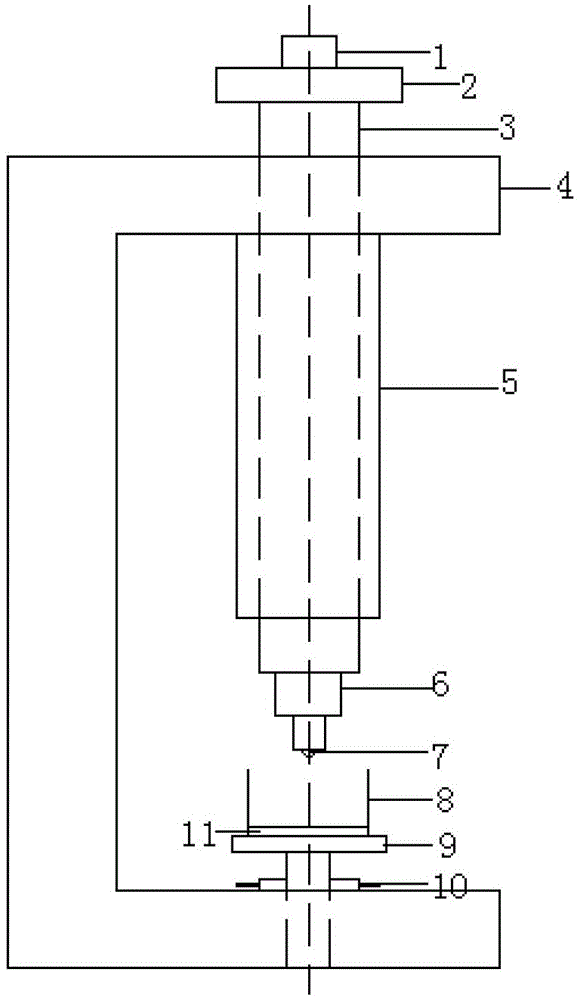

A continuous loading indentation type stress corrosion test machine and test method

A stress corrosion and testing machine technology, which is applied in weather resistance/light resistance/corrosion resistance, wear resistance testing, measuring devices, etc., can solve the problems of failing to meet the experimental requirements, and achieve low cost, good stability, and medium types controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

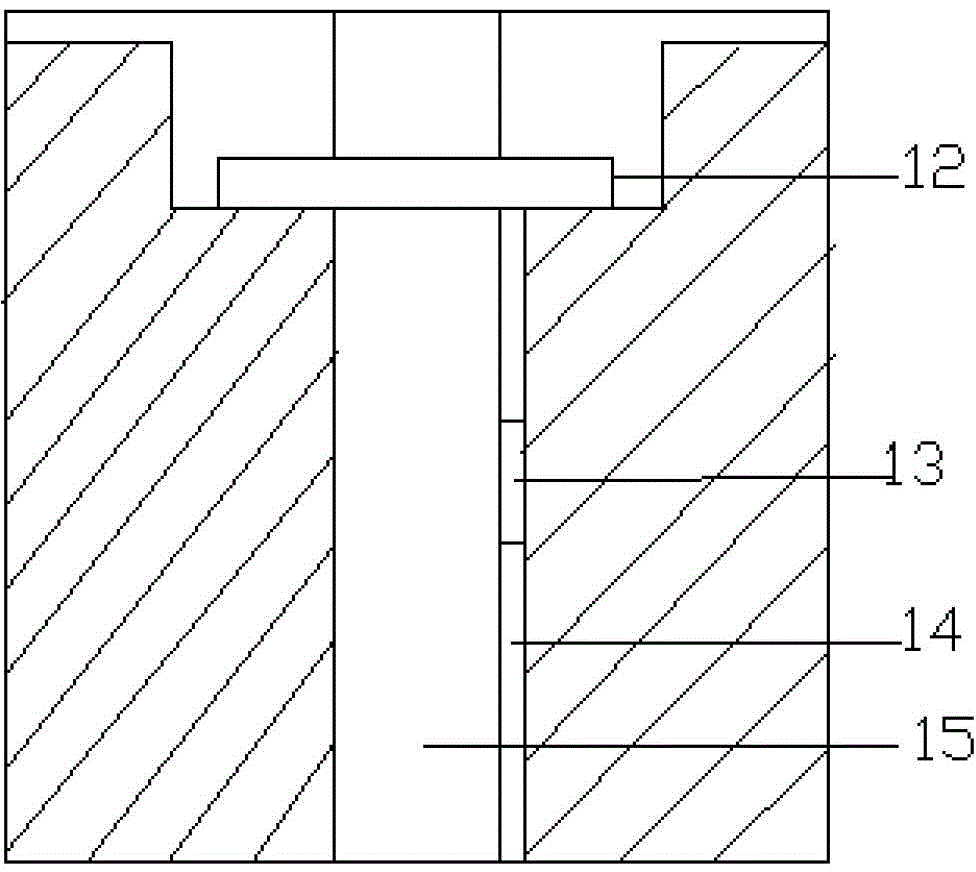

Embodiment Construction

[0026] First, the theoretical basis and research results of the present invention are introduced in detail.

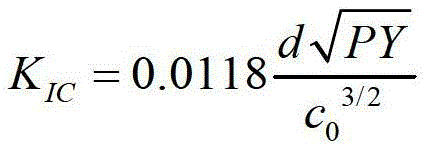

[0027] First analyze the unloading indentation crack, there is residual tensile stress after the indentation crack is unloaded, and the stress factor K caused by the residual stress r Equal to the fracture toughness K of the indentation crack IC :

[0028] K IC = 0.0118 d PY c 0 3 / 2

[0029] where: c 0 : Original length of crack, d: Diagonal length of indentation, P: Load magnitude, Y: Elastic modulus. Since in the environmental medium, the adsorption of medium molecules on the crack tip can reduce the atomic bonding force, and the adsorption of medium molecules on the crack tip can reduce the atomic bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com