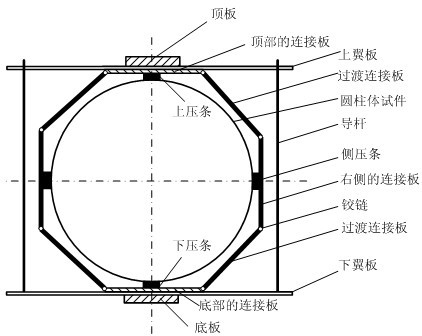

Fixture and test method for two-way alternating split test of road material cylinder specimen

A technology for road materials and cylinders, which is used in the analysis of materials, the use of repetitive force/pulse force to test the strength of materials, and measurement devices, etc. Fatigue resistance of pavement materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Both the embodiment 1 and the embodiment 2 use the above-mentioned fixture to carry out the bidirectional alternate splitting fatigue test of the specimen.

[0035] Example 1 Bidirectional Alternate Splitting Fatigue Test of Asphalt Mixture Cylindrical Specimen with a Diameter of 100mm

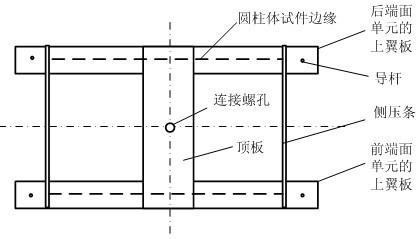

[0036] (1) The size and material of the main components of the test fixture

[0037] The cylindrical specimen used for the test has a diameter of 100 mm and a height of 40 mm. The dimensions of the main components of the corresponding fixture are shown in Table 1.

[0038]

[0039] The length of each bead is 60mm, so that when the specimen is placed in the middle of the fixture, 10mm is left at both ends of the specimen.

[0040] The guide rod is a cylinder with a diameter of 4mm and a length of 150mm.

[0041] The material of each component of the fixture is alloy high carbon steel with a tensile strength of 600MPa. The friction force of the hinge is less than 0.1N. After c...

Embodiment 2

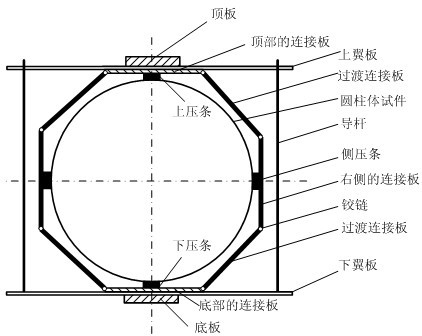

[0057] Example 2 Two-way Alternate Splitting Fatigue Test of Asphalt Mixture Cylindrical Specimen with a Diameter of 150mm

[0058] (1) The size and material of the main components of the test fixture

[0059] The cylindrical specimen used for the test has a diameter of 150 mm and a height of 60 mm. The dimensions of the main components of the corresponding fixture are shown in Table 2.

[0060]

[0061] The length of each bead is 80mm, so that when the specimen is placed in the middle of the fixture, 10mm is left at both ends of the specimen.

[0062] The guide rod is a cylinder with a diameter of 4mm and a length of 200mm.

[0063] The material of each component of the fixture is alloy high carbon steel with a tensile strength of 800MPa. The friction force of the hinge is less than 0.1N. After calibration, when a tensile force of 10kN is applied on the top plate of the fixture, the pressure transmitted to the side pressure bar on the specimen is 9.99kN.

[0064] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com