True triaxial hydraulic coupling test device for realizing visualization based on biaxial rheometer

A hydraulic coupling and test device technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of less research on evolution laws, unsatisfactory, lack of crack networks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

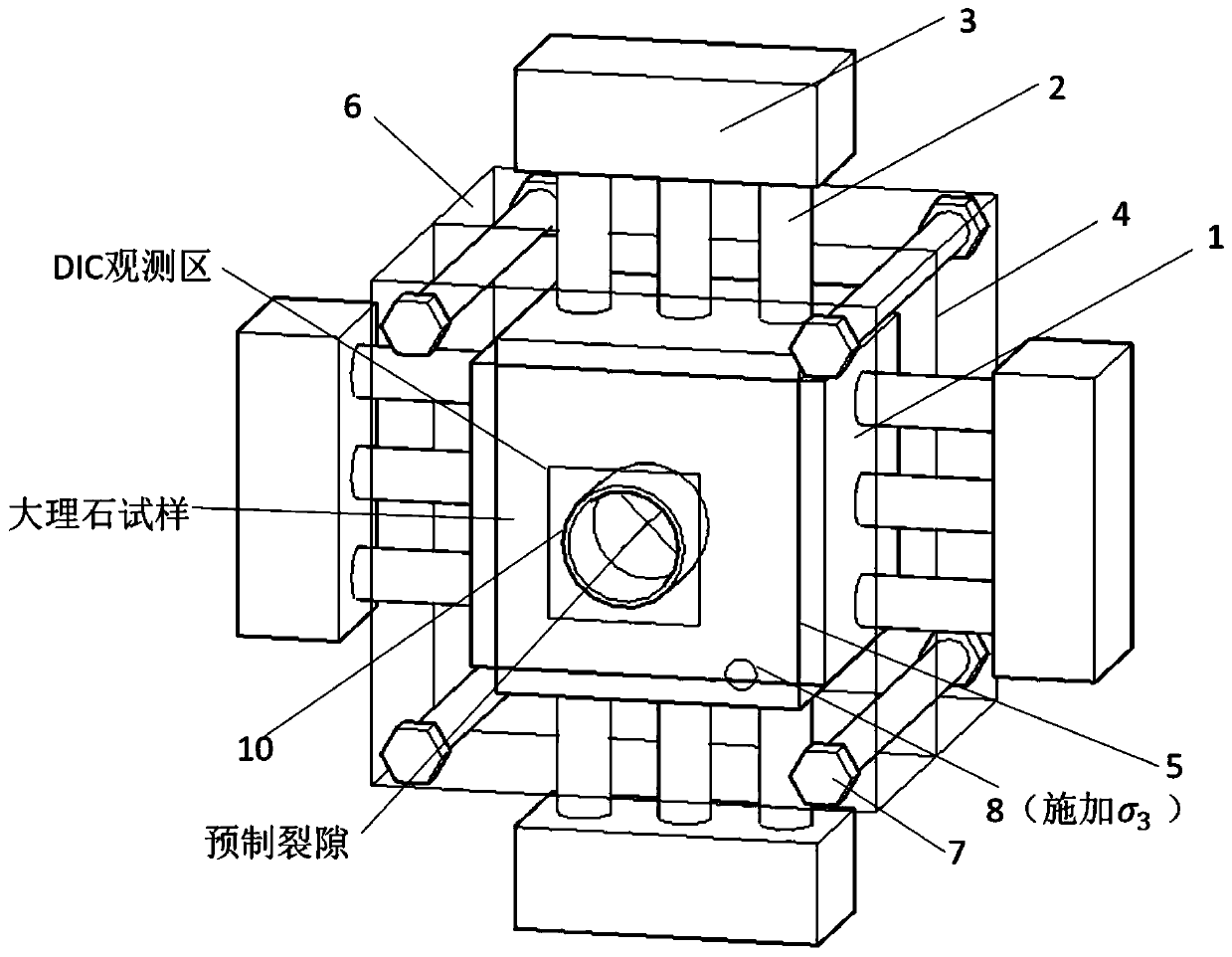

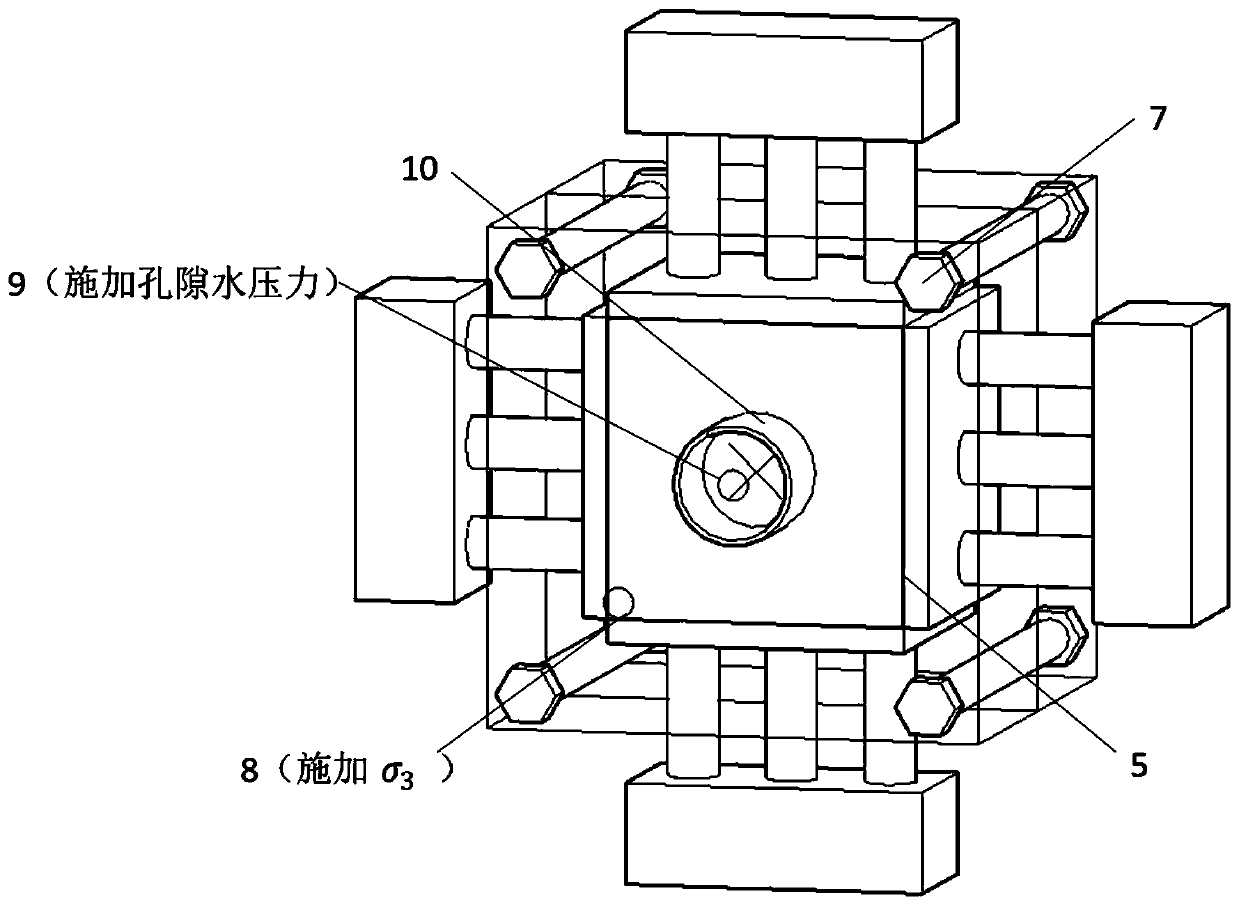

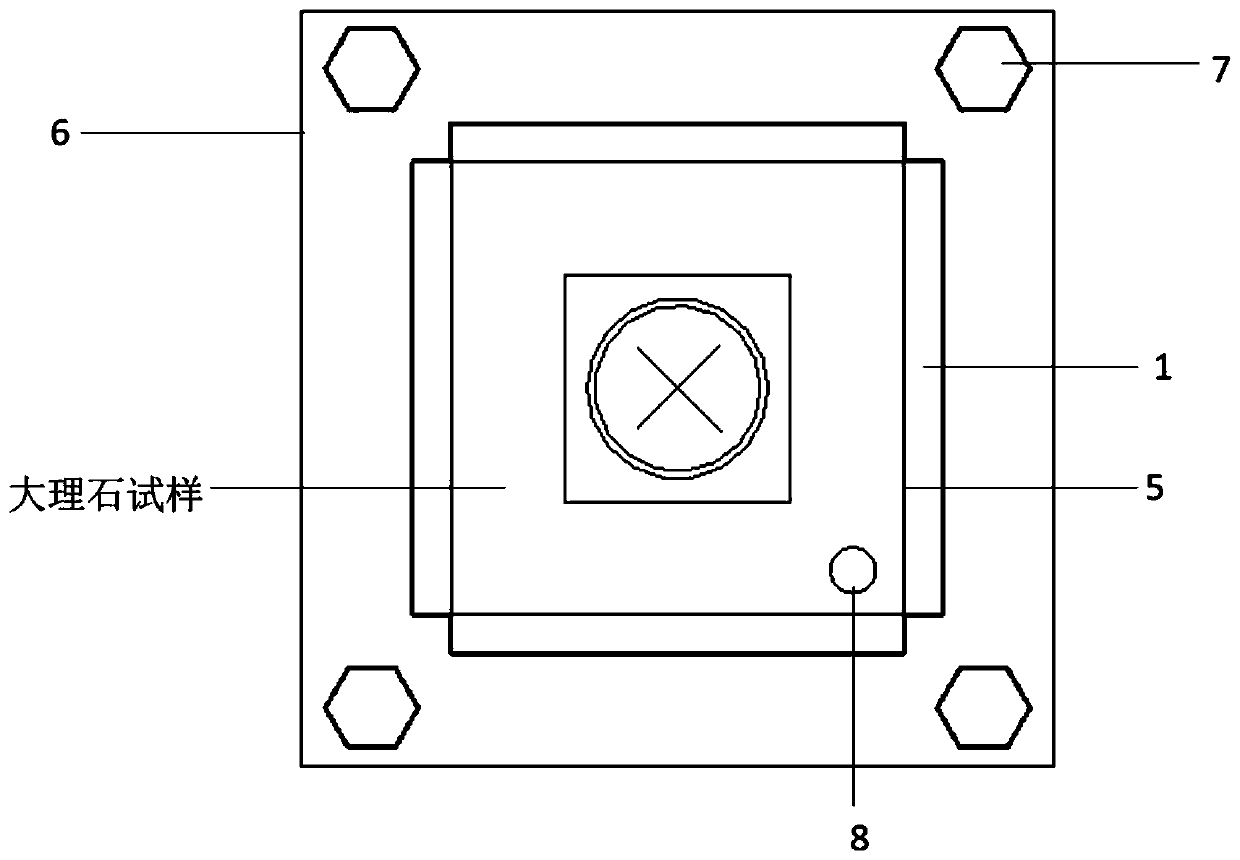

[0029] Such as Figure 1-4 As shown, the present invention provides a real triaxial hydraulic coupling test device based on a biaxial rheometer to realize visualization, the device includes a loading gasket 1, an axial force transmission member 2, a biaxial rheometer loading plate 3, and a rubber gasket 4. Confining pressure seal ring 5, modified polycarbonate plate 6, fastening bolt 7, oil injection hole 8, water injection hole 9, pore water pressure seal ring 10. During the test, prepare a marble sample with a specification of 50mm×150mm×30mm, use a water jet to make a prefabricated crack through the middle of the front of the sample, cover the four sides of the sample with rubber confining pressure sealing ring 5, and use rubber The marble sample covered by the sealing ring 5 is fixed on the loading plate 3 through the loading pad 1 and the axial force transmission member 2 . Fix the pore hydraulic sealing ring 10 at the center of the front and back of the sample, seal the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com