High-performance spray-applied waterproof acrylate material and preparation method thereof

An acrylate and spray film waterproof technology, applied in the direction of coating, can solve the problems of reduced strength, easy cracking, long particle size of continuous basalt fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

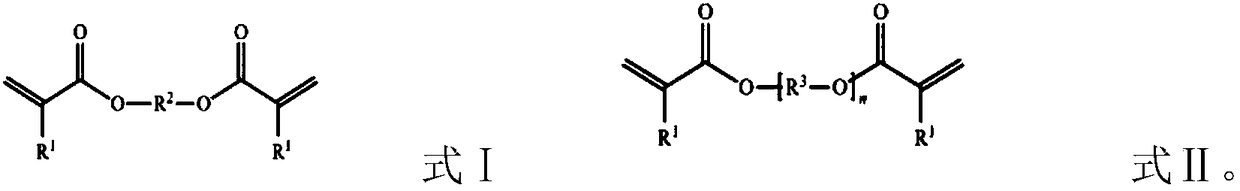

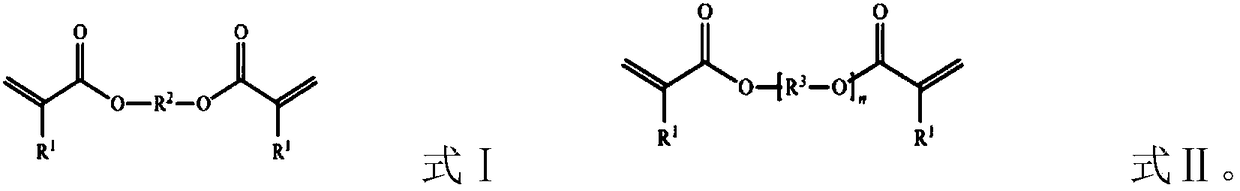

[0022] Another aspect of the present invention provides a method for preparing the above-mentioned high-performance acrylate spray film waterproofing material, the preparation method comprising: adding an acrylate aqueous solution containing two C=C double bonds and passing a flexible carbon chain between the two double bonds The linked compound and optional pigment and / or co-solvent are mixed uniformly, divided into two parts A and B, and mixed with the oxidizing agent and the reducing agent respectively. The "mixing with the oxidizing agent and the reducing agent separately" means that one part is mixed with the oxidizing agent, and the other part is mixed with the reducing agent.

[0023] According to the present invention, the ratio of A part to B part can be determined according to needs, preferably, the ratio of A part to B part is 0.01:1-1:0.01.

[0024] As a preferred solution, all raw materials for preparing the high-performance acrylate spray film waterproofing mater...

Embodiment 1

[0027] In parts by weight, the raw materials for preparing the waterproof material of this embodiment are: 55 parts of magnesium acrylate aqueous solution with a mass concentration of 45%, 10 parts of octylene glycol dimethacrylate, 5 parts of sodium persulfate, and 5 parts of triethanolamine And 30 parts of light calcium carbonate.

[0028] Concrete preparation steps are as follows:

[0029] Mix magnesium acrylate aqueous solution, octylene glycol dimethacrylate, and light calcium carbonate, disperse at high speed, stir evenly, divide into two parts A and B at a ratio of 1:1, and add sodium persulfate and triethanolamine respectively.

Embodiment 2

[0031] In parts by weight, the raw materials for preparing the waterproof material of this embodiment are: 50 parts of magnesium acrylate aqueous solution with a mass concentration of 45%, 10 parts of polypropylene glycol dimethacrylate, 5 parts of ammonium persulfate, and 5 parts of sodium thiosulfate. Parts, 2 parts of fumed silica, 30 parts of heavy calcium carbonate and 5 parts of propylene glycol.

[0032] Concrete preparation steps are as follows:

[0033] Mix magnesium acrylate aqueous solution, polypropylene glycol dimethacrylate, propylene glycol, fumed white carbon black, and heavy calcium carbonate, disperse at high speed, stir evenly, divide into two parts A and B according to the ratio of 1:1, and add over Ammonium Sulfate and Sodium Thiosulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com